Bottle cap assembling machine

A technology for assembly machines and bottle caps, which is applied to household components, household appliances, and other household appliances, and can solve problems such as low production efficiency, high floor space, and complex structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

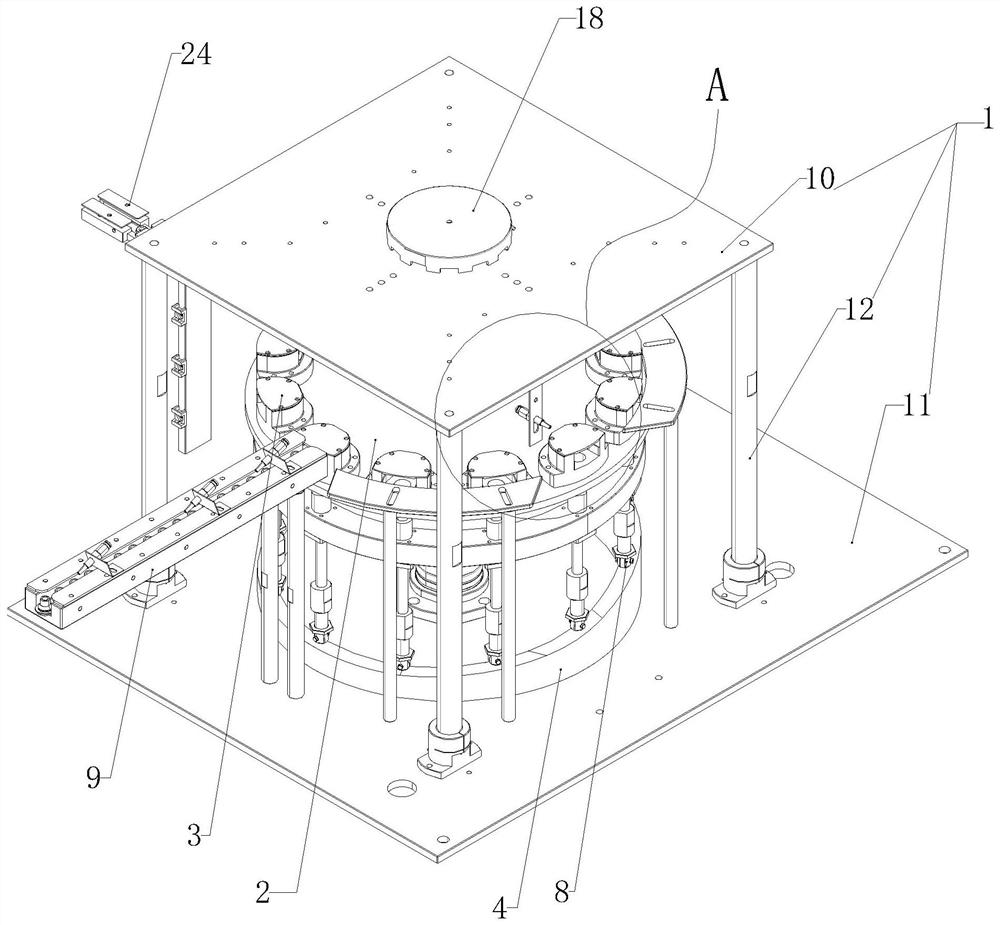

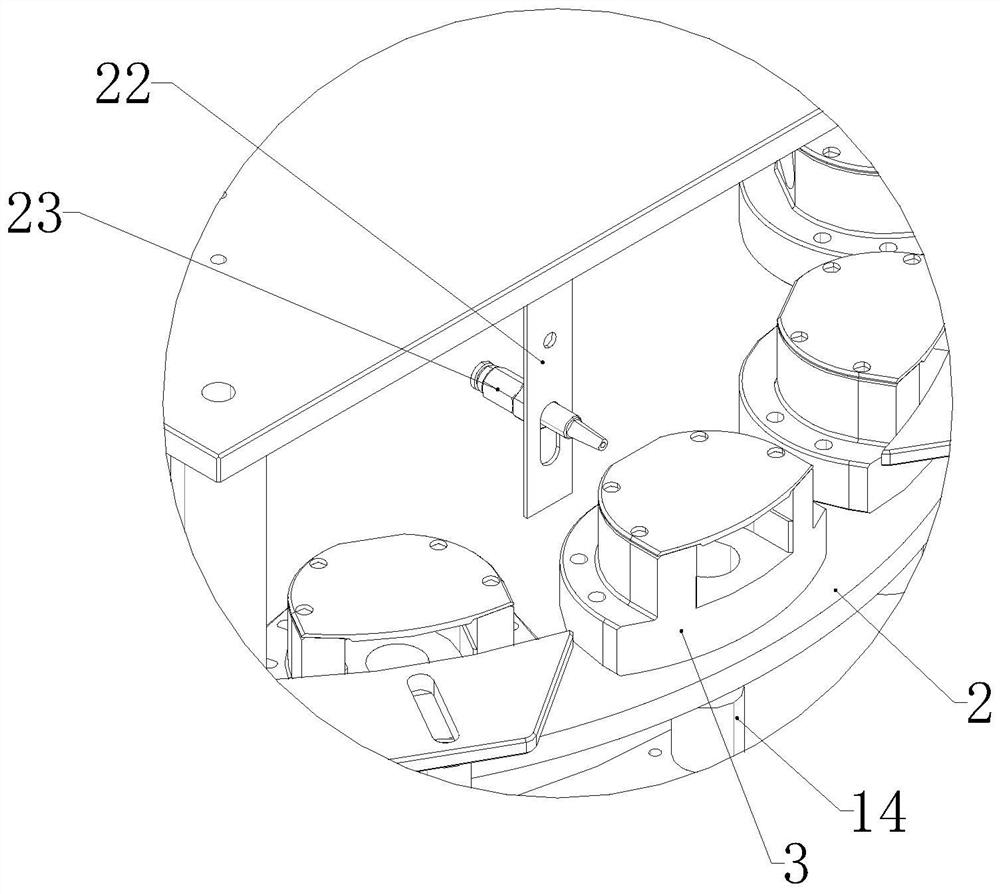

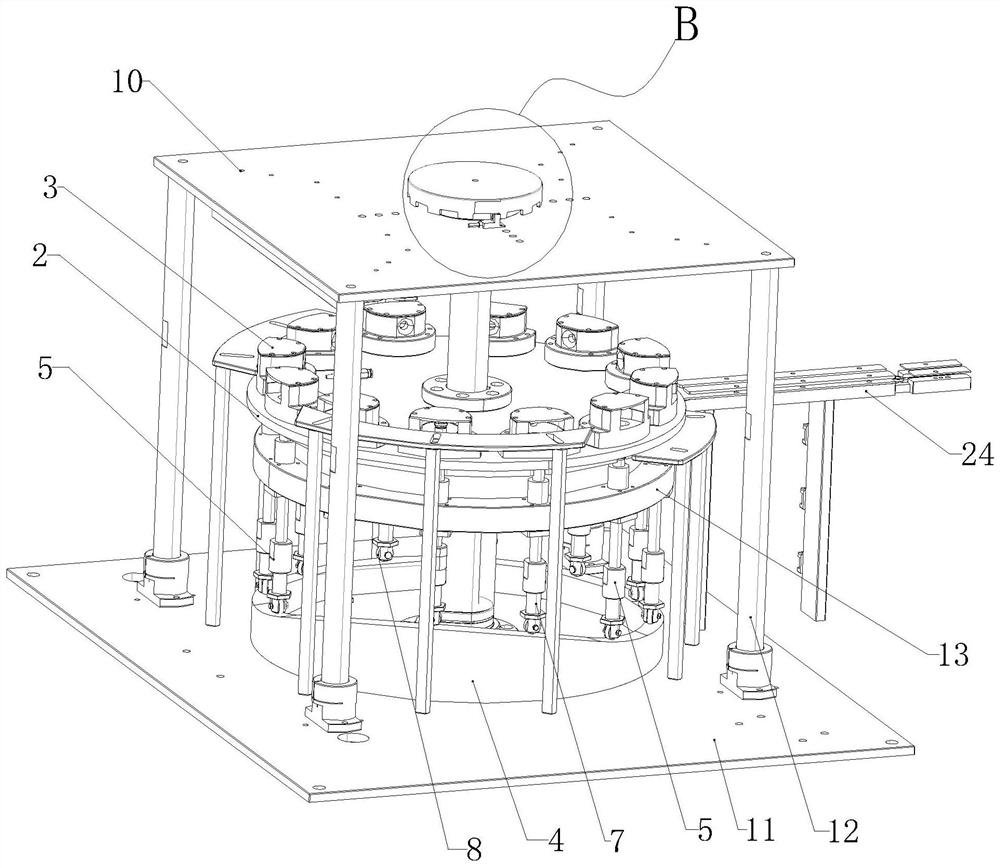

[0026] see Figure 1 to Figure 8 , the bottle cap assembly machine of a preferred embodiment of the present invention includes a bottle cap assembly assembly, the bottle cap assembly assembly includes a fixed frame 1, a turret 2 whose central axis is rotatably arranged on the fixed frame, and is arranged on the surface of the turret and A plurality of assembly seats 3 distributed around the central axis of the turret, a cam plate 4 arranged above or below the turret, and a push rod assembly 5 arranged between the cam plate and the turret;

[0027] The assembly seat is fixed on the turret, an assembly cavity is provided in the assembly seat, an input and output port commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com