Automatic assembly method and system for swing lever type positive and negative electrode pieces

A technology of positive and negative plates and assembly methods, which is applied in the direction of electrode manufacturing, electrolytic capacitors, capacitor manufacturing, etc., can solve the problems of difficulty in meeting the output and quality requirements of such products, lagging behind the development of the battery industry, and low output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

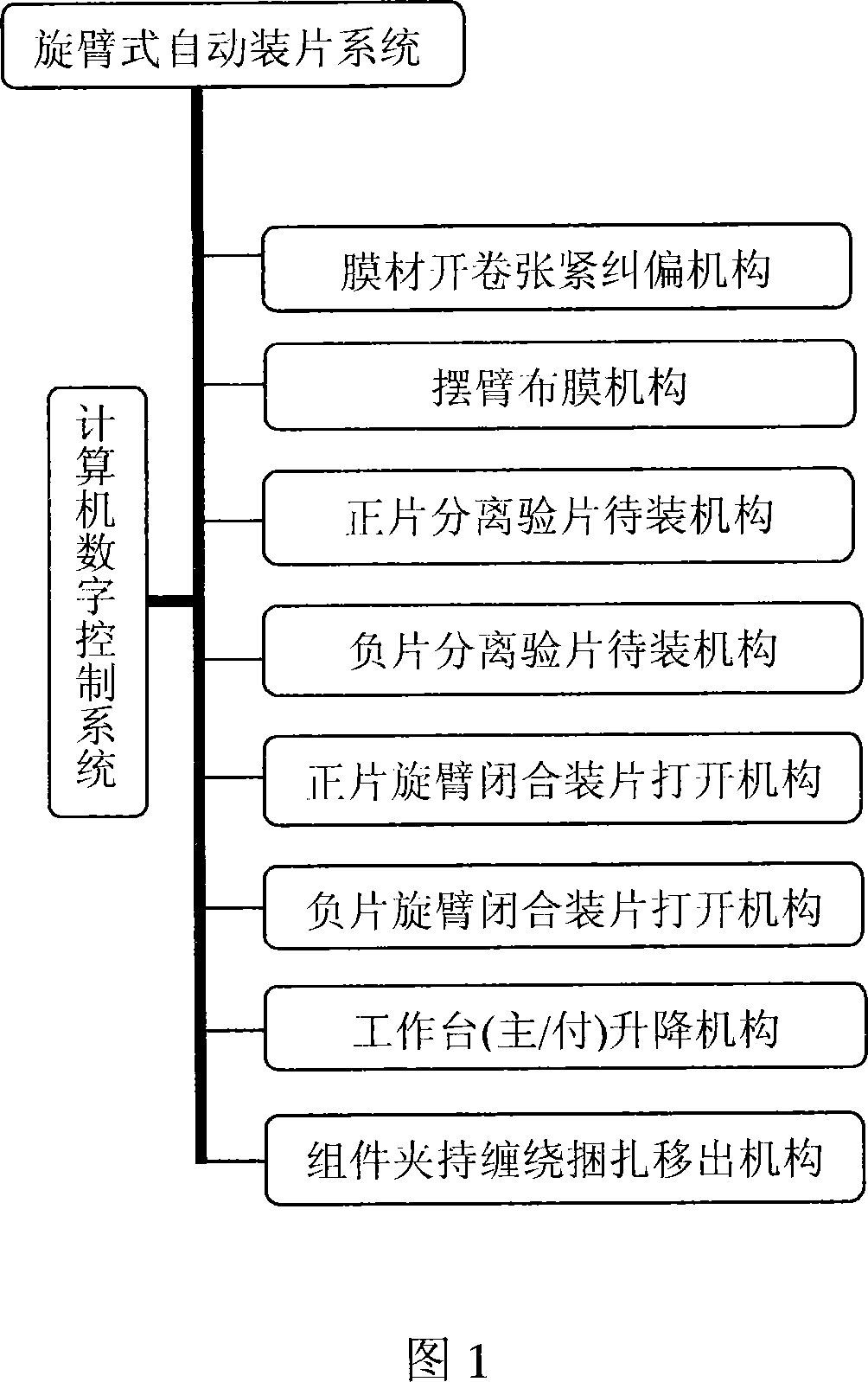

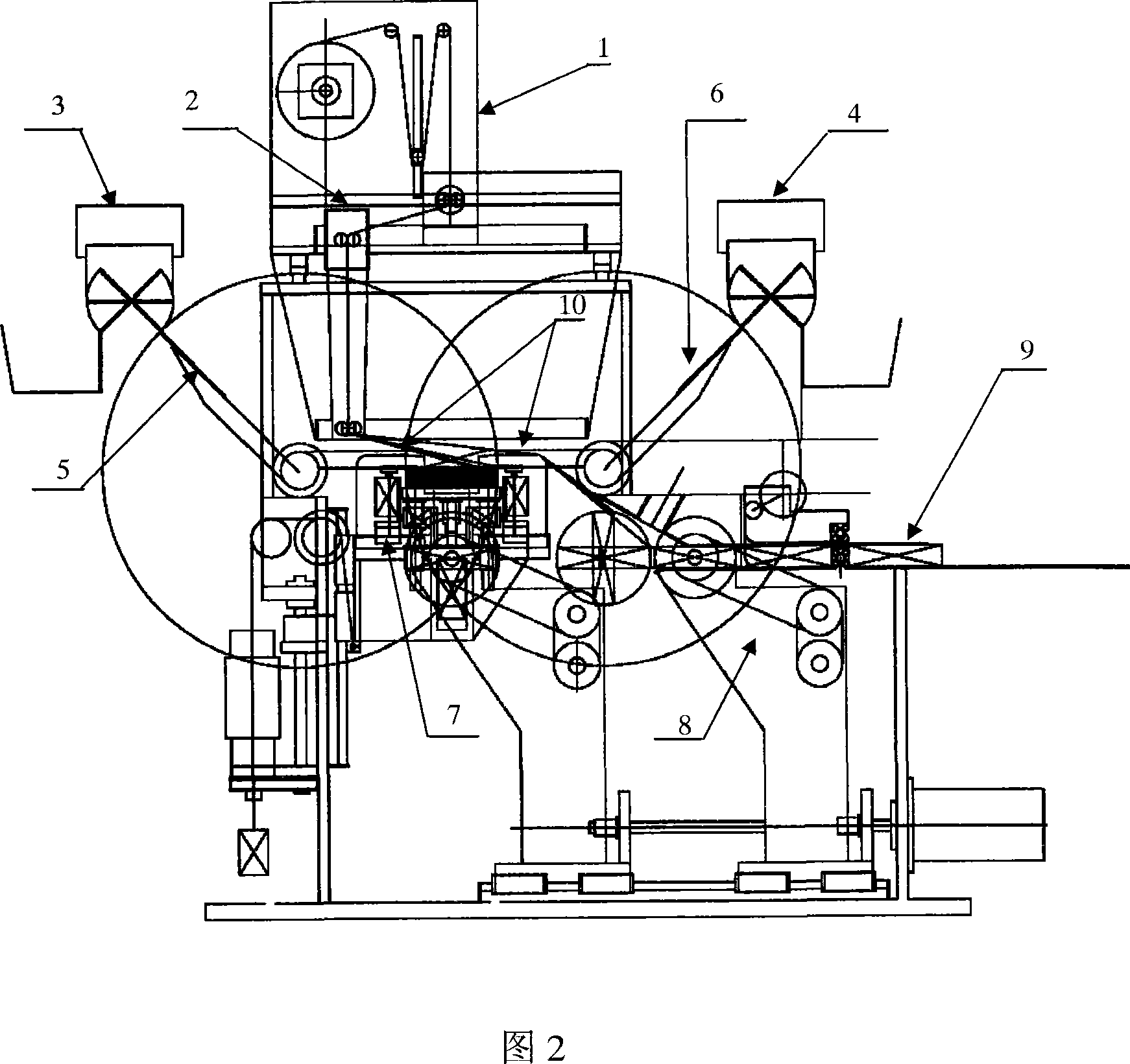

[0027] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Through the description of the preferred embodiments of the present invention, the advantages of the present invention can be seen and understood more clearly.

[0028] The present invention comprises the steps:

[0029] a) Separating and inspecting the pole pieces stacked in the positive and negative pole pieces one by one, and moving them to their respective positions to be assembled;

[0030] b) Unwind the isolation film and guide it to tension and rectify it, and use the swing arm to place the film between the positive and negative plates;

[0031] c) Use two sets of swing arms with controllable opening and closing widths to rotate in opposite directions to alternately install the positive and negative electrodes at their respective positions to be assembled between the separators, and press them into a stack on the workbench;

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com