Cotton fabric garment surface fluff impurity removal process

A cotton fabric and clothing technology, applied in the field of clothing processing, can solve the problems of low impurity removal efficiency, fluff polluting the air environment, clothing impurity removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

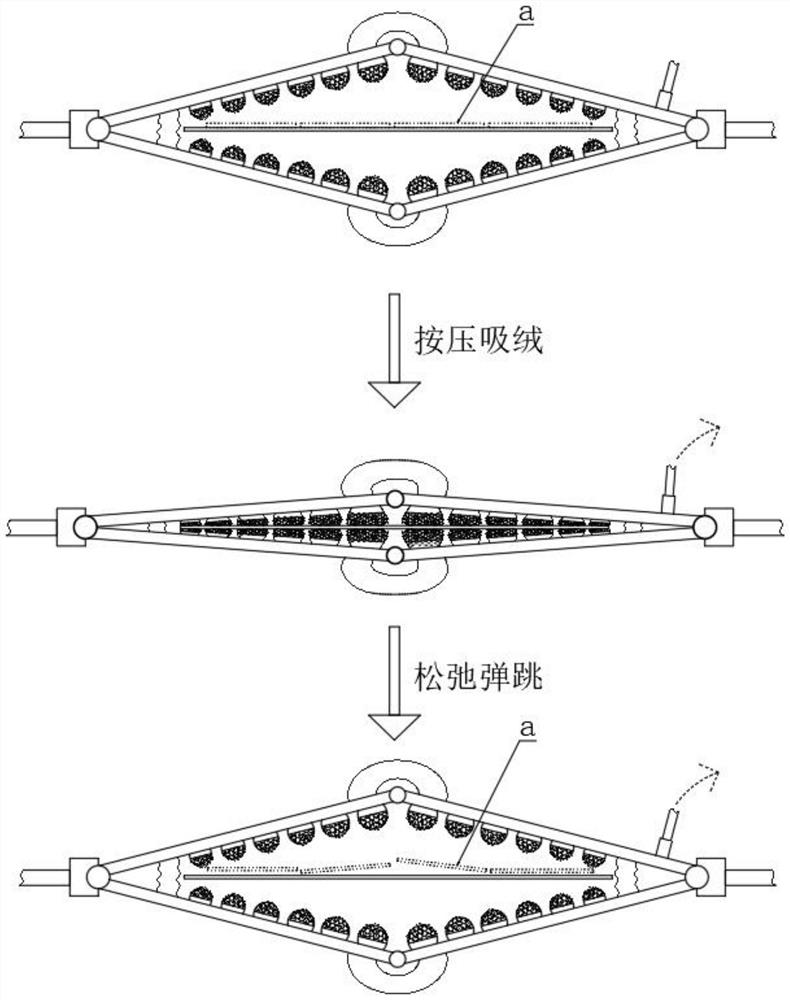

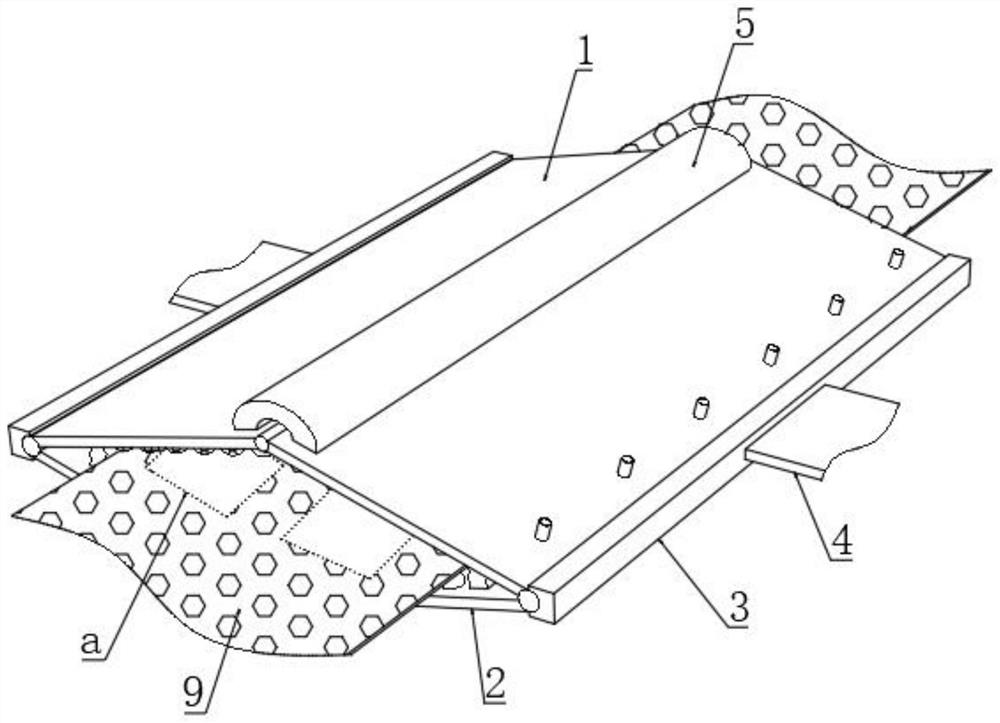

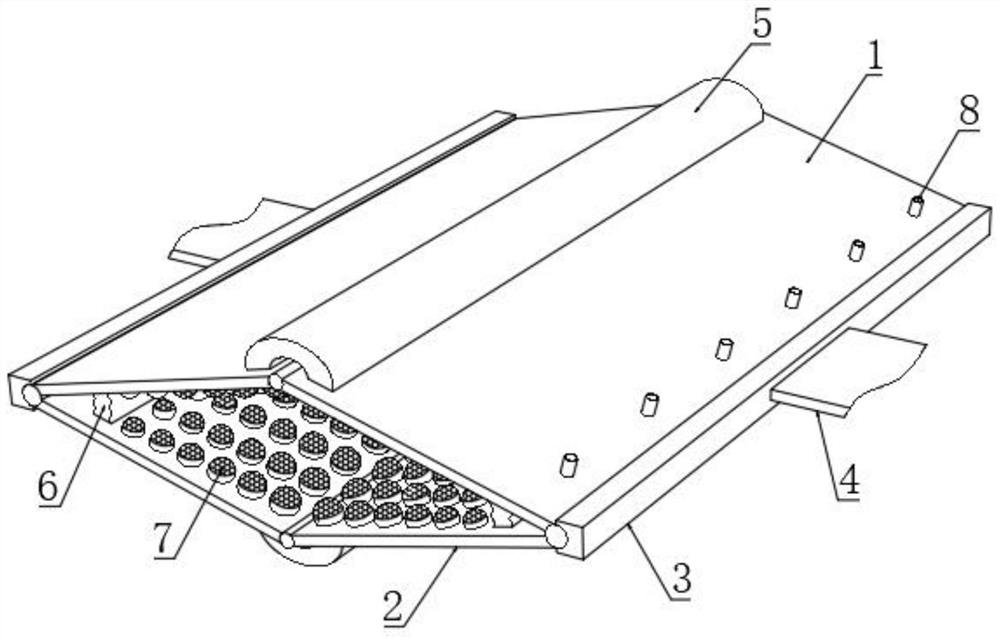

[0047] see figure 1 and figure 2 , a process for removing impurities on the surface of cotton fabric garments, comprising the following steps:

[0048] S1, the clothing to be processed (such as figure 1 and figure 2 The letter a) in is placed flat on the pad net 9, and the traction roller is started to drive the pad net 9 to move, and the garment is moved to the inner side of the diamond-shaped double-sided impurity remover;

[0049] S2. Connect one end of the shunt air duct to the suction pump, and the other end to the diamond-shaped double-sided impurity remover;

[0050] S3. Start the suction pump and cylinder. On the one hand, the cylinder drives the diamond-shaped double-sided impurity remover to perform circular telescopic movement to absorb the short fleece on the surface of the garment. On the other hand, the air suction pump drives the internal airflow of the diamond-shaped double-sided impurity remover , to collect the linters that have been adsorbed on the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com