Excavator bucket capable of preventing bucket teeth from falling off

A technology for excavators and buckets, which is applied in the field of excavator accessories, and can solve the problems of inconvenient installation of pin shafts and easy loss of springs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

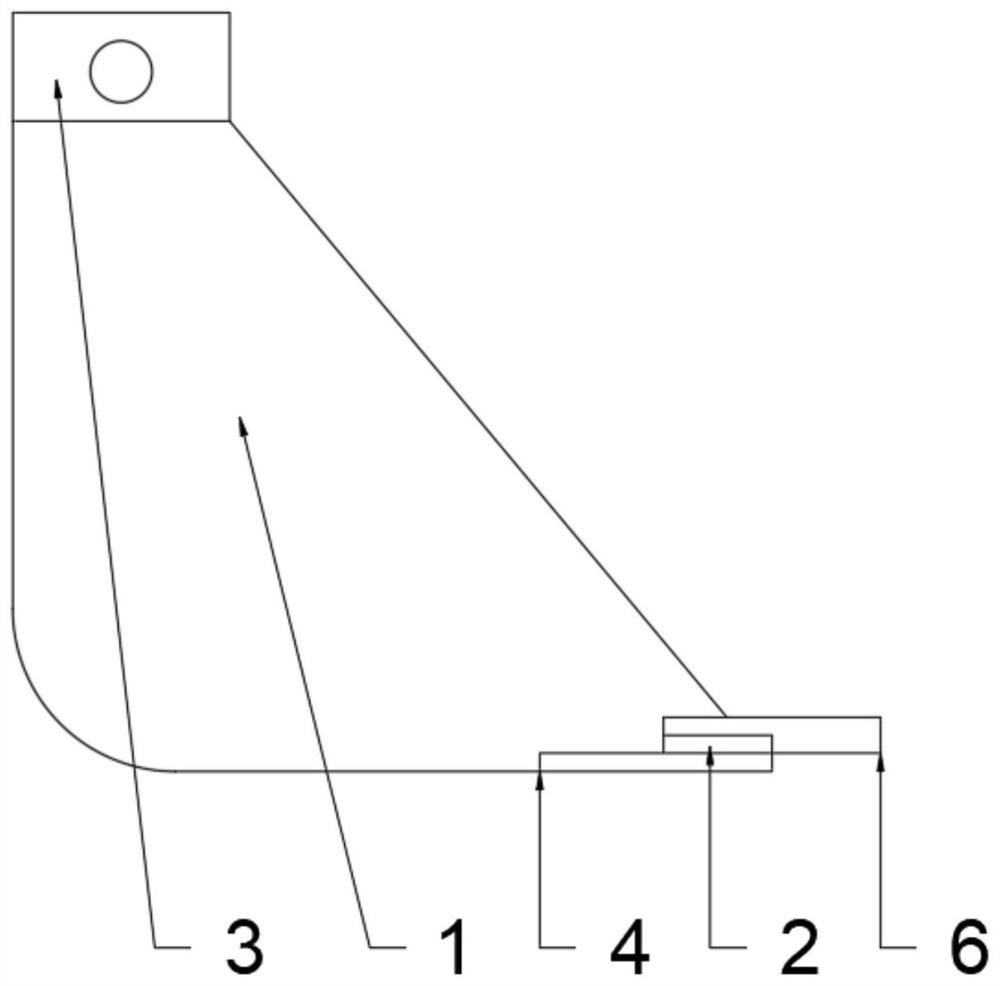

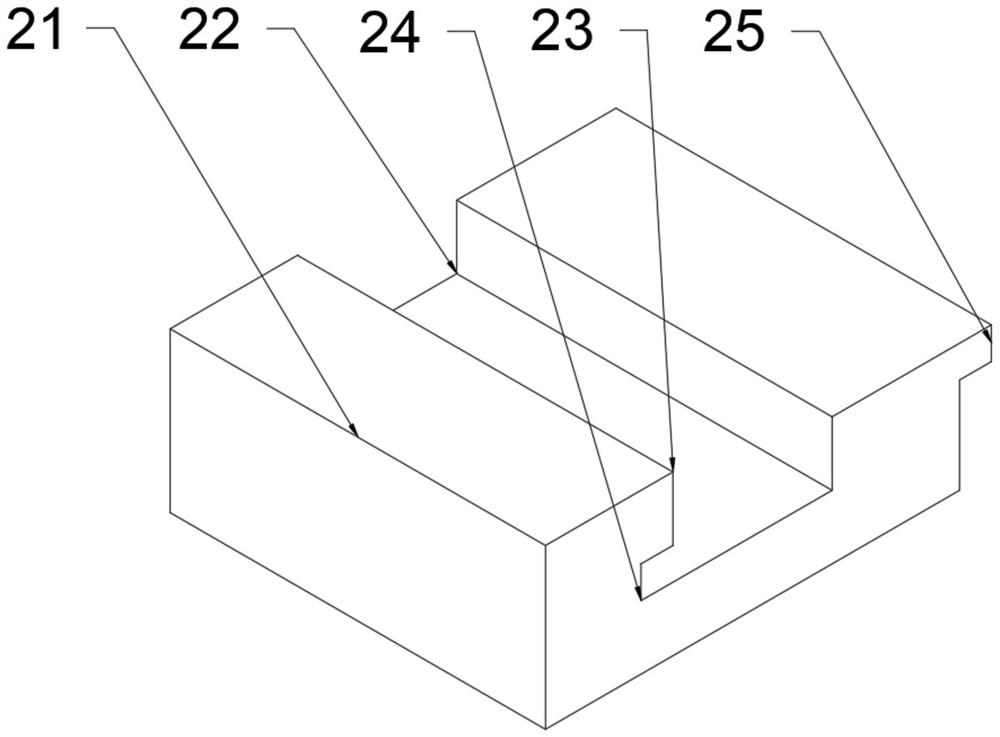

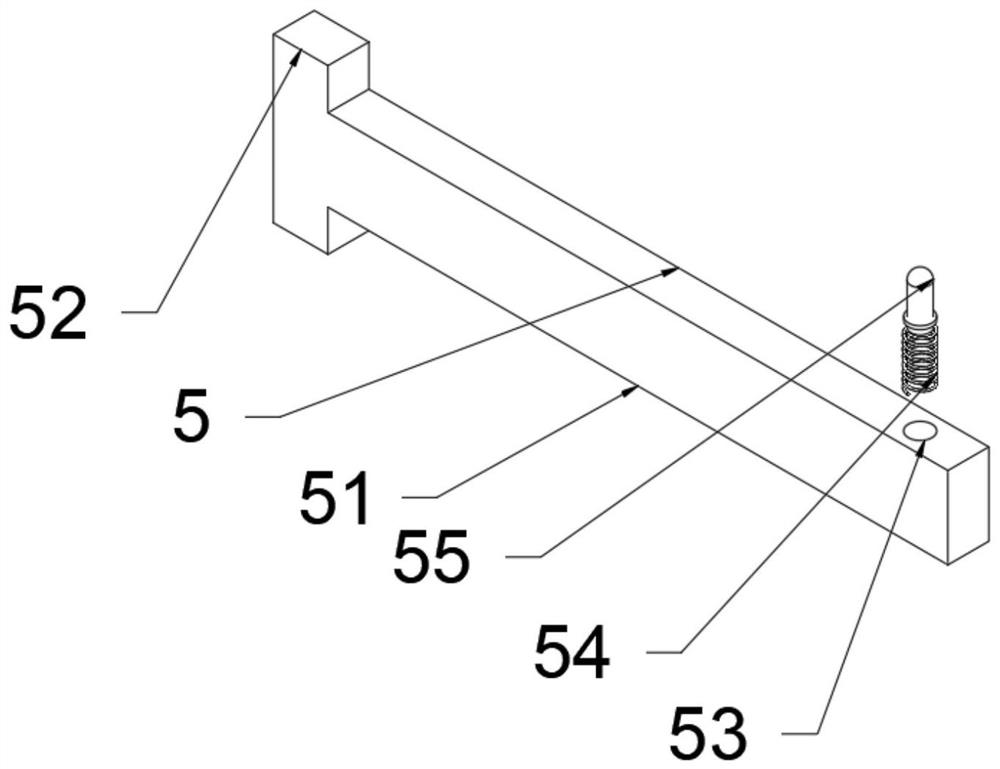

[0022] Example 1: Please refer to Figure 1-4 , an excavator bucket that prevents bucket teeth from falling off, comprising a bucket body 1 and a fixing seat 2, the upper end of the bucket body 1 is fixedly connected with a connecting seat 3, the upper end of the bottom plate of the bucket body 1 is fixedly connected with a tooth plate 4, the tooth plate 4 The upper end is fixedly connected with a number of fixed seats 2, and the fixed seats 2 are detachably connected with bucket teeth 6 through pin shafts 5. The fixed seats 2 include the main body 21 of the fixed seat and the first groove 22. The first groove 22, the upper side of the left wall of the first groove 22 is fixedly connected with the first longitudinal block 23, and the lower end of the first block 23 forms a longitudinal first block with part of the left wall and part of the lower wall of the first groove 22. Two grooves 24, the right end of the main body 21 of the fixing seat are fixedly connected with the seco...

Embodiment 2

[0029] Embodiment 2: This embodiment is a further improvement of the previous embodiment: Considering that most of the slider 55 is exposed outside the ninth groove 53 under the action of the spring 54, it is difficult to pass through the eighth groove 610 when installing the pin shaft 5 The slider is pressed into the ninth groove 53 , and an obliquely downward guide groove is opened on the front wall of the eighth groove 610 on the upper side, and the slider 55 is pressed into the ninth groove 53 through the guide groove.

[0030] The working principle of the present invention is: when the bucket tooth 6 needs to be installed, the tooth seat 61 of the bucket tooth 6 and the fixed seat 2 are installed in cooperation with each other, the tooth seat 61 is pushed to the left, the first block 23 enters the fourth groove 65, The second block 25 enters the seventh groove 68, and the third block 64 enters the second groove 24. After the slider of the pin shaft 5 is pressed down, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com