Freezing and thawing cycle frozen soil shearing device capable of reducing normal pressure errors

A freeze-thaw cycle, normal pressure technology, used in the direction of using a stable shear force to test the strength of materials, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

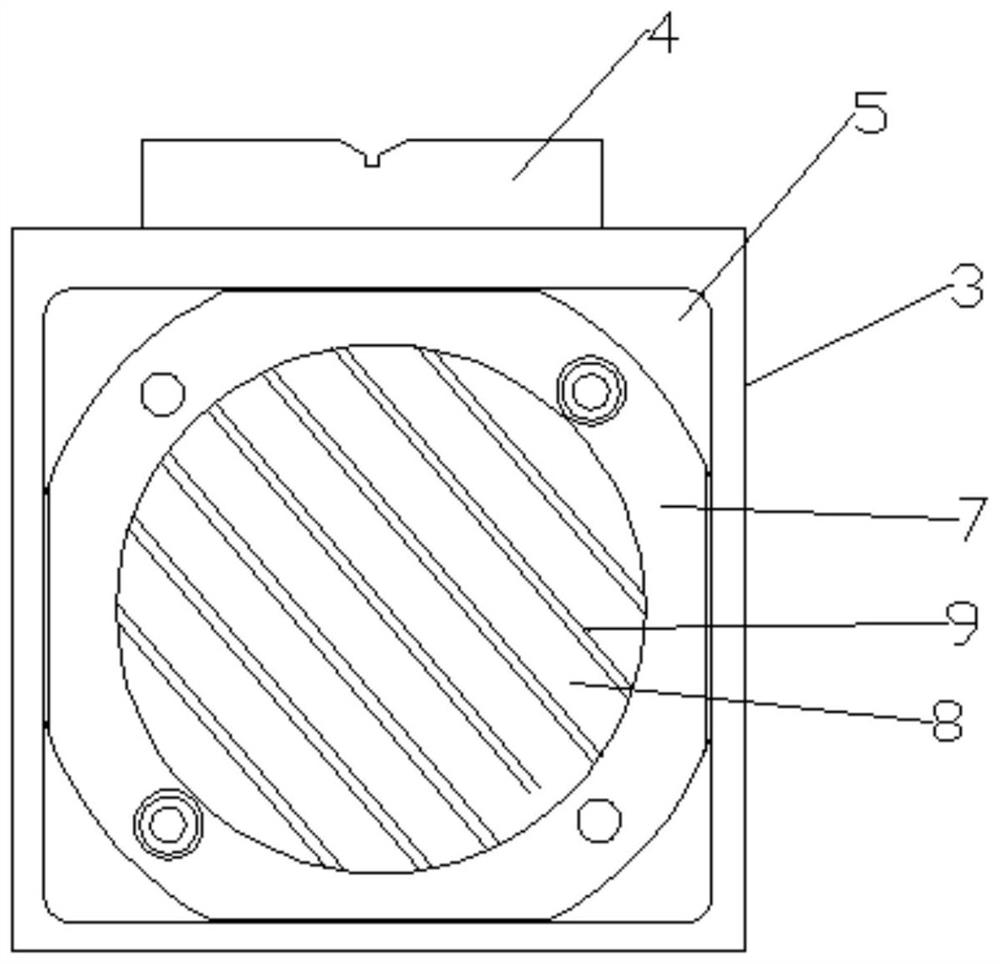

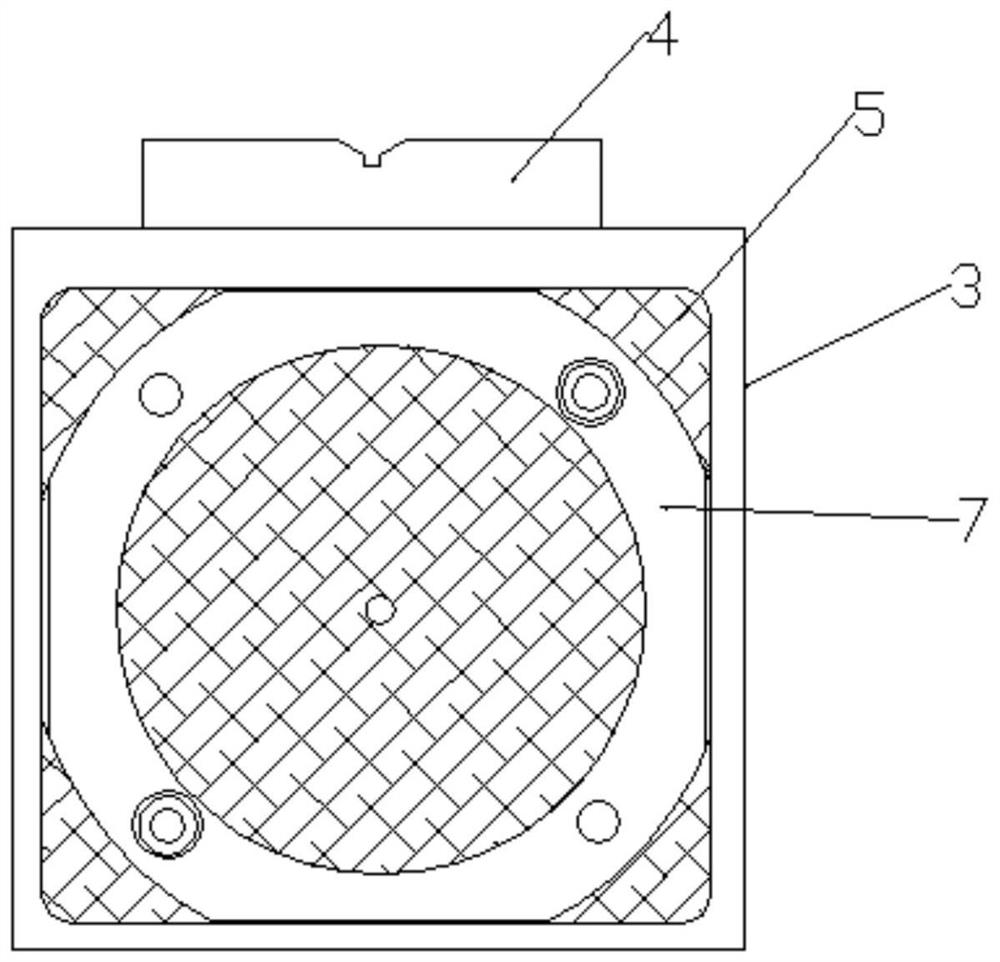

[0033] The upper shear box 1 and the lower shear box 2 all include a box body 3, one end of the box body 3 is provided with a connecting block 4, and the middle part of the box body 3 is provided with a placement groove 5, so that The bottom end of the placement groove 5 is provided with an annular groove 6, and a collar 7 connected to the annular groove 6 is arranged in the placement groove 5, and a cutter head 8 is arranged at the middle part of the collar 7, and the cutter head 8 is provided with a number of inclined slots 9, and the box body 3 is located in the middle of the placement slot 5 and is provided with a shaft hole 10 connected with the cutter head 8. Both the upper shear box 1 and the lower shear box 2 are made of stainless steel, and the connection between the upper shear box 1 and the lower shear box 2 adopts a rolling structure that ensures a gap. Both ends of the collar 7 are provided with a number of installation holes 11 , and the obliquely symmetrical end...

Embodiment 2

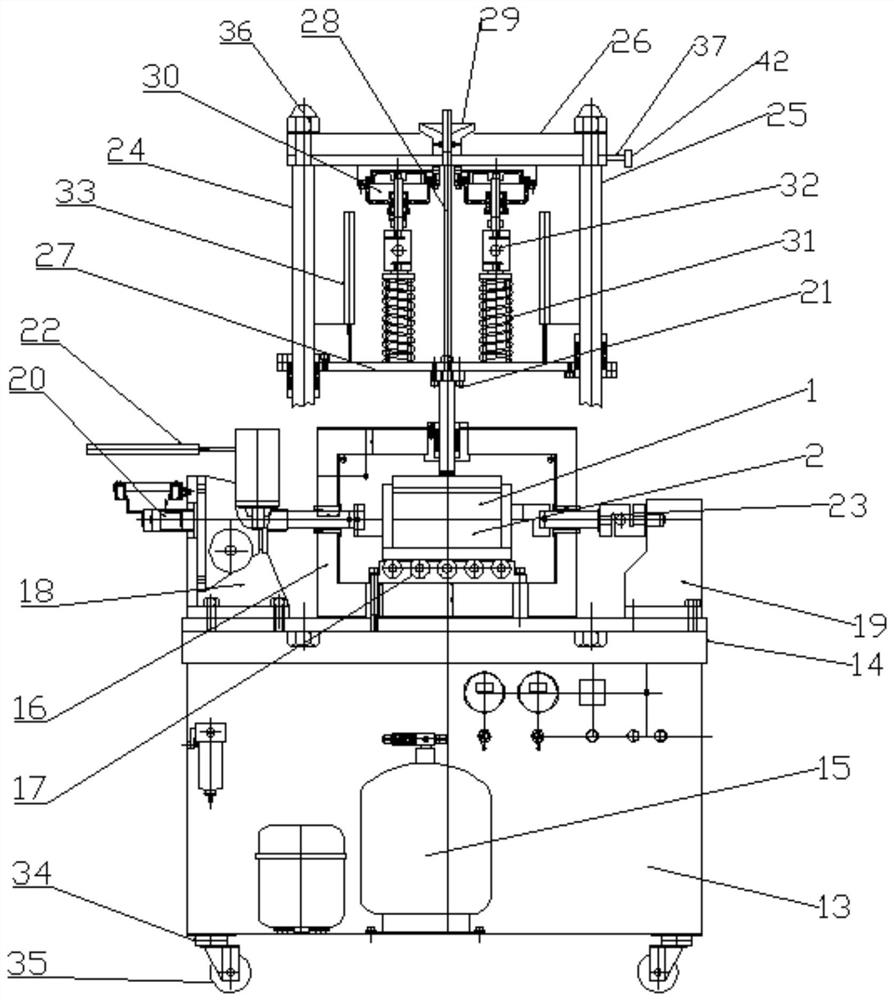

[0035] A shearing displacement sensor 22 matched with the shearing pushing device is arranged in the middle of the upper end of the supporting block one 18 . A horizontal load sensor 23 is arranged between the support block 2 19 and the upper shear box 1 . A normal displacement sensor 33 is arranged on one side of the upper end of the cross bar 27 , and an electric proportional valve is arranged on the rolling diaphragm cylinder 30 .

Embodiment 3

[0037] The cold bath device 16 includes a cold bath box located outside the upper shear box 1 and the lower shear box 2, a circulation pump inside the support box 13, the upper shear box 1 and the lower shear box 1. A shear circulation pipeline is arranged inside the shear box 2, and the circulation pump is connected with the shear circulation pipeline through a connecting pipe. The lower ends of the support boxes 13 are provided with several bearing blocks 34 , the number of the bearing blocks 34 is four, and the bottom ends of the bearing blocks 34 are provided with universal wheels 35 . The number of the receiving gear 47 connected to the rotating gear 48 is four, and the threaded cylinder 49 is matched with the normal plate 26 .

[0038] In order to facilitate the understanding of the above-mentioned technical solution of the present invention, the working principle or operation mode of the present invention in the actual process will be described in detail below.

[0039...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap