High-precision combined leveling method suitable for standard rice seedling raising shed

A high-precision, standard technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

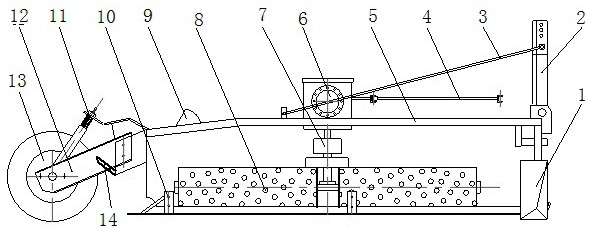

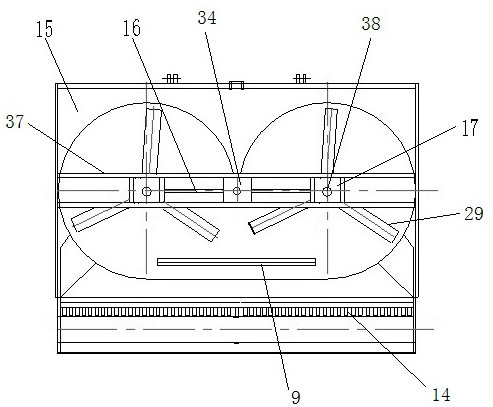

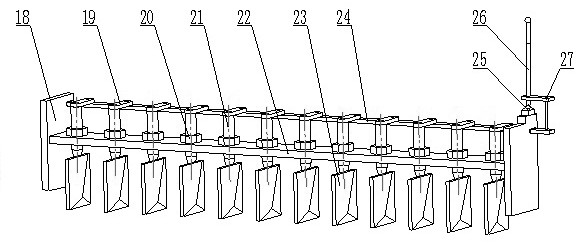

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

[0027] This high-precision combined leveling method suitable for standard rice seedling sheds: through the combined leveling machine that integrates the square coulter 23, the rotary leveler and the suppression roller, the combined leveling machine is used to pull the combined leveling machine by a tractor. Combination of crushing-flat-pressing finishing process to complete the fine leveling base surface of seedling raising;

[0028] When leveling the base surface for seedling raising, the combined leveler moves forward with the tractor, first cuts the shallow surface soil layer through the square coulter 23 at the front end of the body frame 5, and then implements the rotary extrusion leveling operation by the rotary leveler, rolling the leveling roller 8 is driven by the power rotation of the central main shaft 38 and moves forward with the leveling machine. Under the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com