Fabricated ground leveling assembly

A prefabricated, ground-based technology, applied to floors, elastic floors, local raised floors, etc., can solve the problems of non-removable replacement, heavy floor load, long construction period, etc., to save use, reduce pollution, and shorten construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

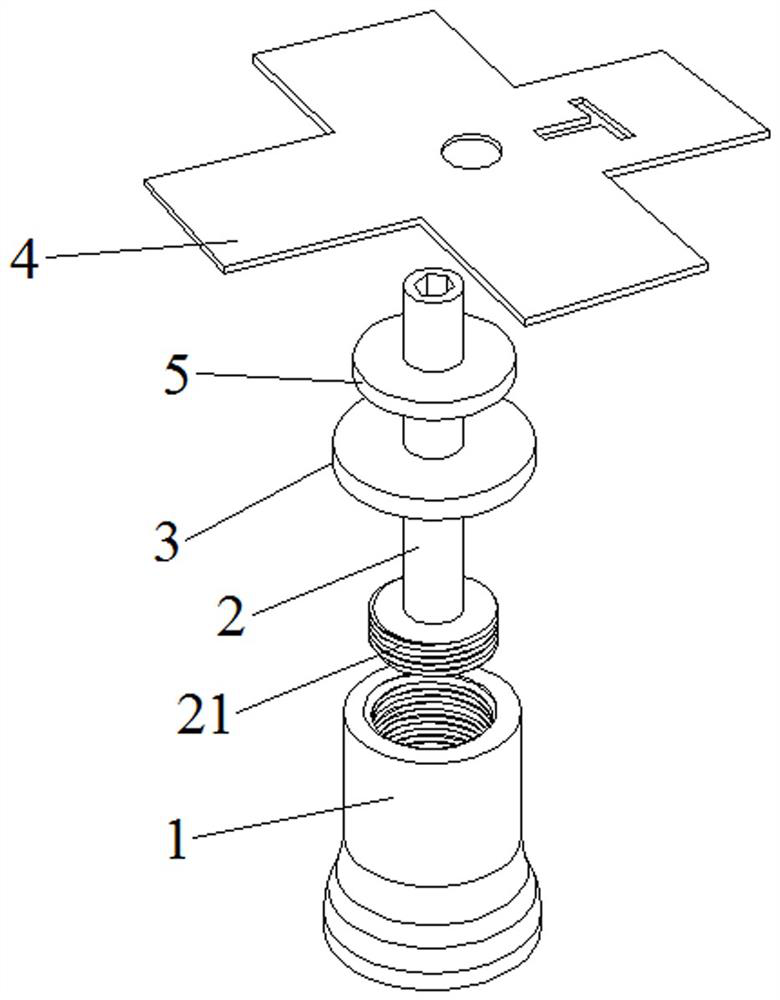

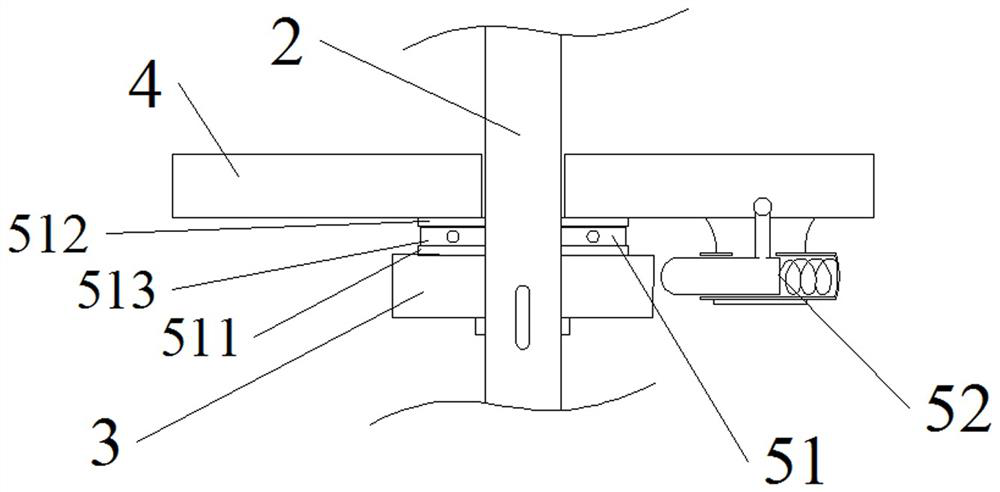

[0030] figure 1 is a schematic diagram of an assembled ground leveling assembly, such as figure 1 As shown, an assembled ground leveling assembly includes a base 1, a leveling screw 2 connected to the base 1, a support 3 arranged on the leveling screw 2 and a cross-shaped floor connector 4 and the rotating mechanism 5 arranged between the supporting member 3 and the floor connecting member 4 so that the two can rotate relatively; the bottom of the leveling screw 2 is provided with an adjusting chassis 21 with threads, and the adjusting The diameter of the chassis 21 is larger than the diameter of the leveling screw 2 .

[0031] The top of the leveling screw 2 is provided with an adjustment hole with an inner hexagonal section, the adjustment hole is a blind hole, and a top cover is arranged on the adjustment hole. The top cover is provided with a prismatic plug matching the adjustment hole.

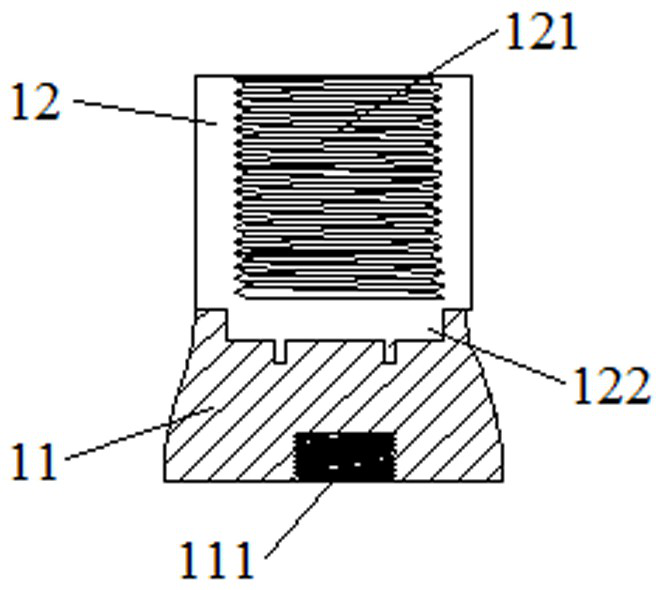

[0032] figure 2 A schematic diagram of the base, such as figure 2 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com