A multi-ingredient mixing and skewering robot for barbecue

A robot and threading technology, which is applied in the field of robots, can solve the problems of low efficiency of manual threading, bacteria in food materials, food material falling, etc., and achieve the effect of speeding up threading speed, reducing contact with food materials, and easy threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

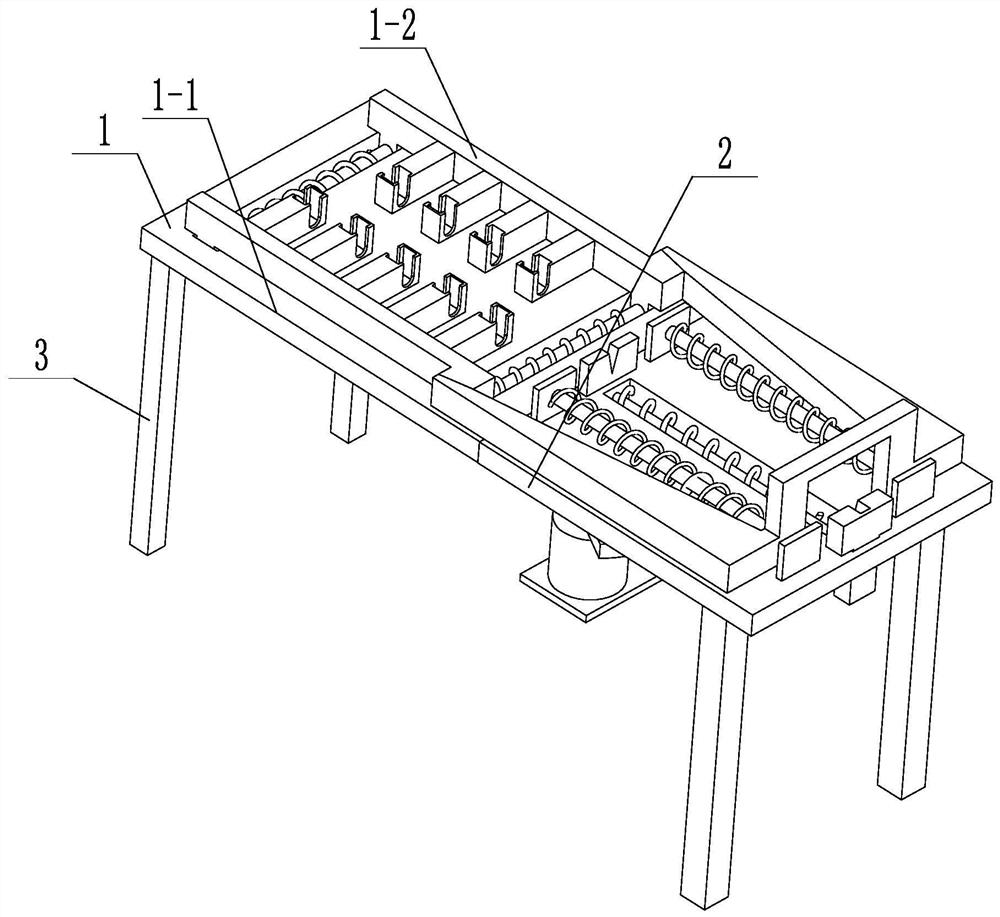

[0014] Specific implementation mode one: as Figure 1 to Figure 5 As shown, this embodiment discloses a multi-ingredient mixing skewering robot for barbecue, including: a fixing device 1, a linkage device 2 and a plurality of table legs 3, one side of the fixing device 1 is horizontally fixedly connected with a linkage device 2, The bottom surface of the fixing device 1 and the linkage device 2 are fixedly connected with a plurality of table legs 3. The fixing device 1 includes: a bottom plate 1-1 and a bending device 1-2, and the bottom plate 1-1 is fixed horizontally on one side. A linkage device 2 is connected, a plurality of table legs 3 are fixedly connected to the lower end of the bottom plate 1-1, and the bottom plate 1-1 is slidably connected with the bending device 1-2.

specific Embodiment approach 2

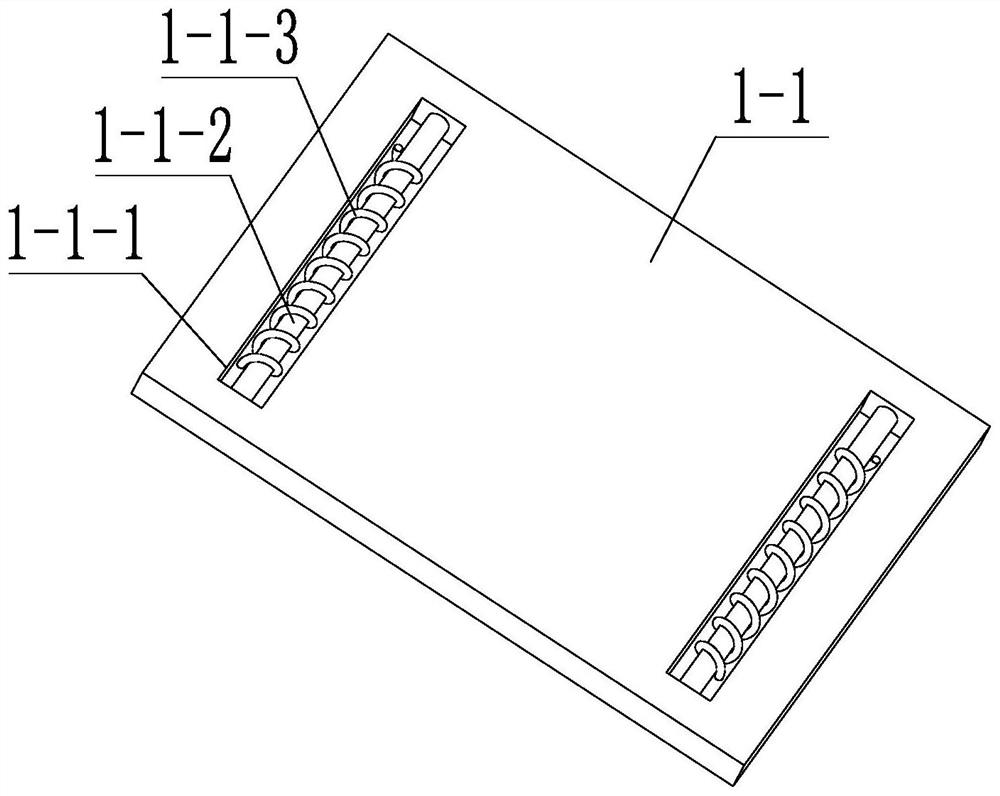

[0015] Specific implementation mode two: as figure 2 As shown, this embodiment is a further description of specific embodiment 1. The bottom plate 1-1 includes: two sliding posts 1-1-2 and two springs 1-1-3. The bottom plate 1-1 The upper end of 1-1 is symmetrically provided with two bottom plate-slots 1-1-1 through its thickness along its length direction, and each of the bottom plate-slots 1-1-1 is horizontally and fixedly connected with a sliding column 1- 1-2, a spring 1-1-3 is provided at the upper end of each sliding post 1-1-2.

specific Embodiment approach 3

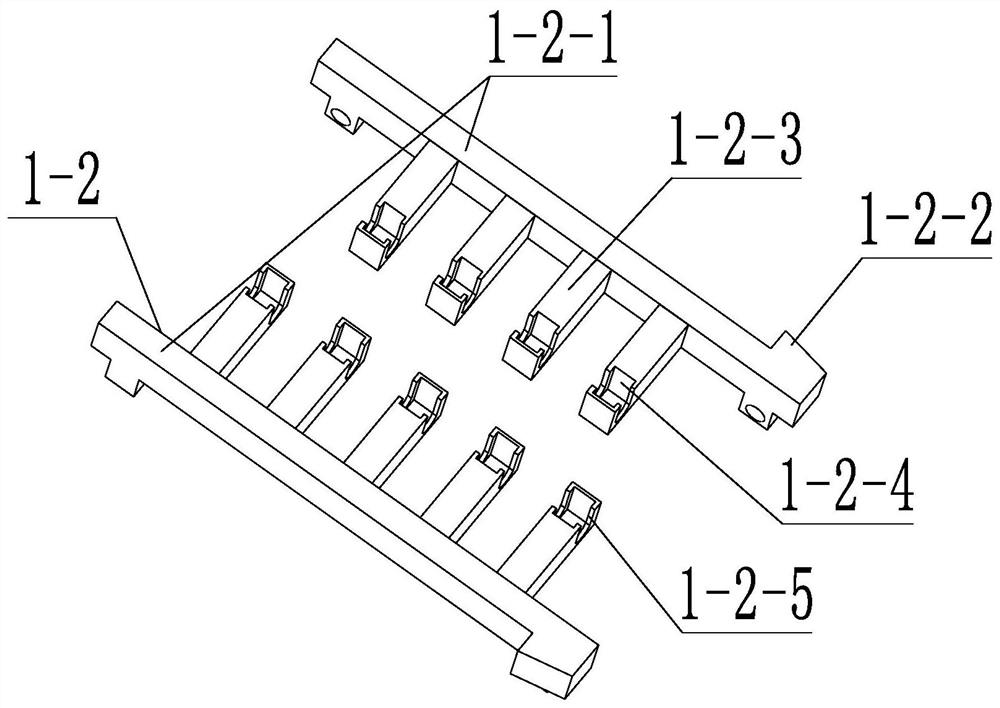

[0016] Specific implementation mode three: as figure 1 , image 3 As shown, this embodiment is a further description of specific embodiment 1. The bending device 1-2 includes: two pillars 1-2-1 and a plurality of push pillars 1-2-3, the two The pillar 1-2-1 is slidably arranged on the two sliding pillars 1-1-2, and the two springs 1-1-3 are arranged between the two pillars 1-2-1, and the two pillars The opposite surface of 1-2-1 is horizontally and fixedly connected with a plurality of push columns 1-2-3, and the plurality of push columns 1-2-3 arranged on the two columns 1-2-1 are arranged alternately, and each of the columns The outer surface of 1-2-1 is respectively provided with inclined-plane protrusions 1-2-2, and each of the push posts 1-2-3 is vertically provided with square grooves 1-2-4, and each of the push posts 1 - 2-3 is horizontally provided with a U-shaped groove 1-2-5 running through its thickness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com