Lens production and injection molding device

A production device and injection molding technology, applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of inconvenient cleaning, low perfusion efficiency, complex structure, etc., and achieve the effect of easy collection and realization of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

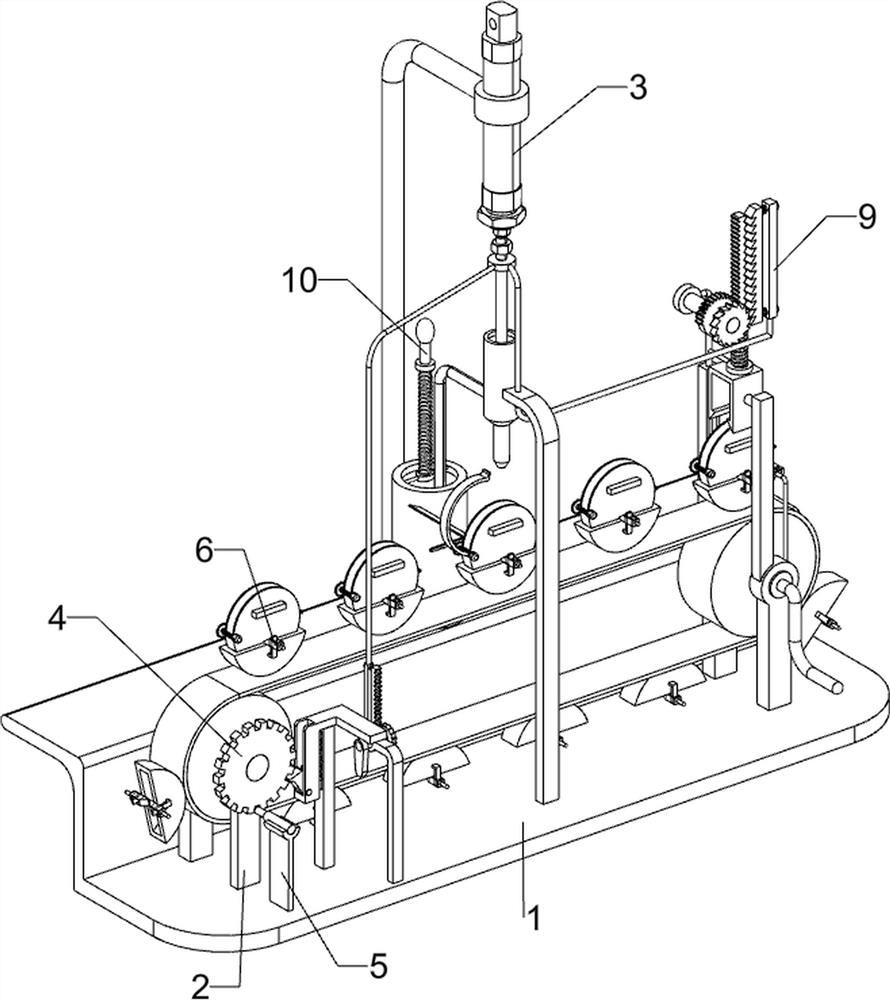

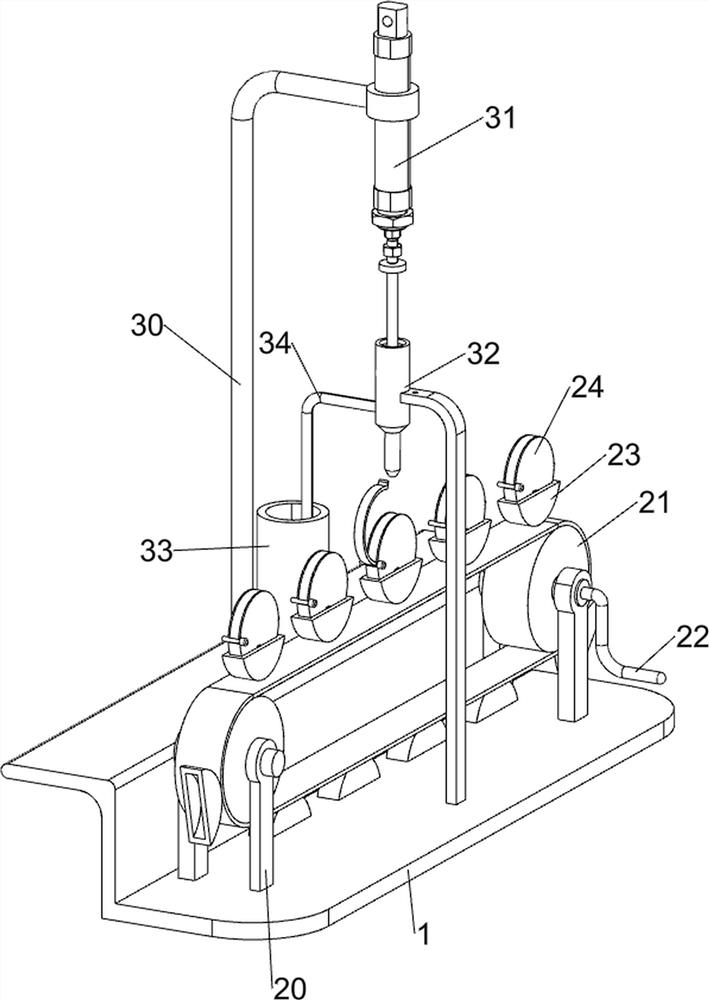

[0036] A lens production device and injection molding device, such as figure 1 with figure 2 As shown, it includes a base 1 , a transmission mechanism 2 and an injection molding mechanism 3 , the base 1 is provided with a transmission mechanism 2 , and the base 1 is provided with an injection molding mechanism 3 .

[0037] When people need to use this device, first people pour resin into the injection molding mechanism 3, and then people can start the injection molding mechanism 3, the injection molding mechanism 3 operates and then injects the resin into the transmission mechanism 2, and when the resin injection is completed, people control the injection molding mechanism 3 reset, and then people rotate the transmission mechanism 2 to make the loading part of the transmission mechanism 2 move to the right. The charging part that has resin is taken off, and resin can be injected in the charging part of conveying mechanism 2 quickly like this, when people do not need to use t...

Embodiment 2

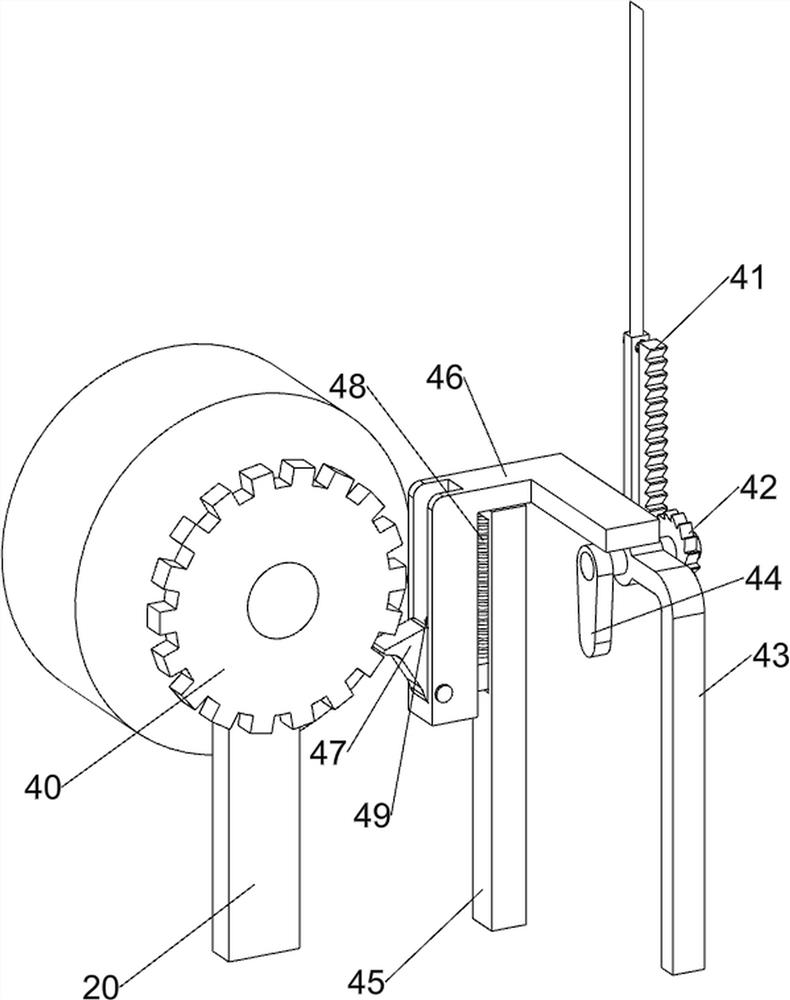

[0042] On the basis of Example 1, such as figure 1 with Figure 3-Figure 11 As shown, the intermittent moving mechanism 4 is also included, and the intermittent moving mechanism 4 includes a first ratchet 40, a first ratchet 41, a second ratchet 42, a second bearing seat 43, a cam 44, a slide rail 45, a slide block 46, a ratchet Claw 47, the first spring 48 and the second spring 49, the left side of transmission assembly 21 is provided with first ratchet 40, is provided with connecting rod on the telescoping rod of cylinder 31, and the sliding type on the left side of connecting rod is provided with first ratchet 41, the second An elastic member is connected between a ratchet 41 and the connecting rod. A second bearing seat 43 is provided on the left front side of the top of the base 1. The second bearing seat 43 is provided with a second ratchet 42. The second ratchet 42 is connected to the first ratchet 41. Mesh, the second ratchet 42 left end is provided with cam 44, is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com