Patents

Literature

36results about How to "Automatically removed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

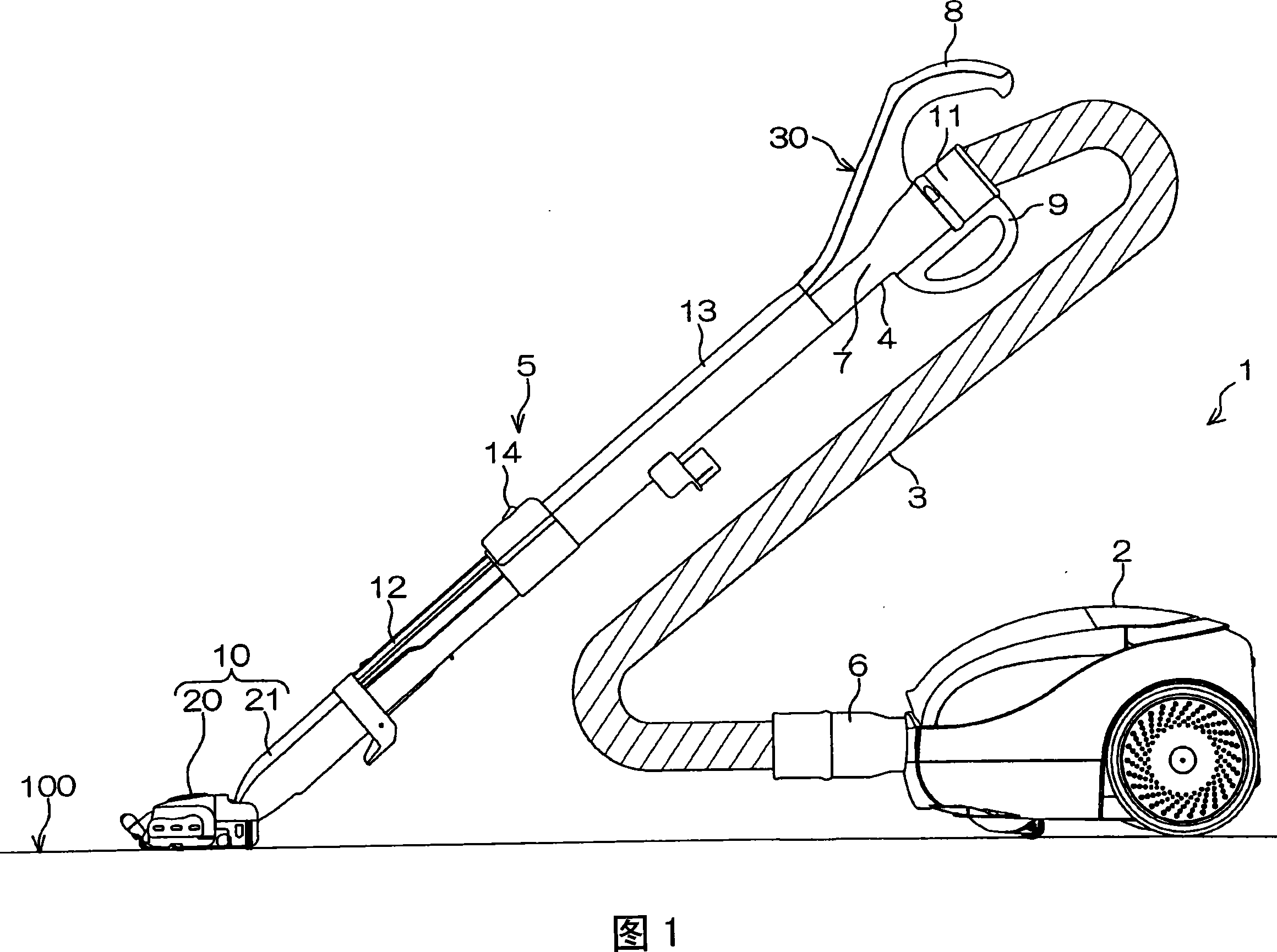

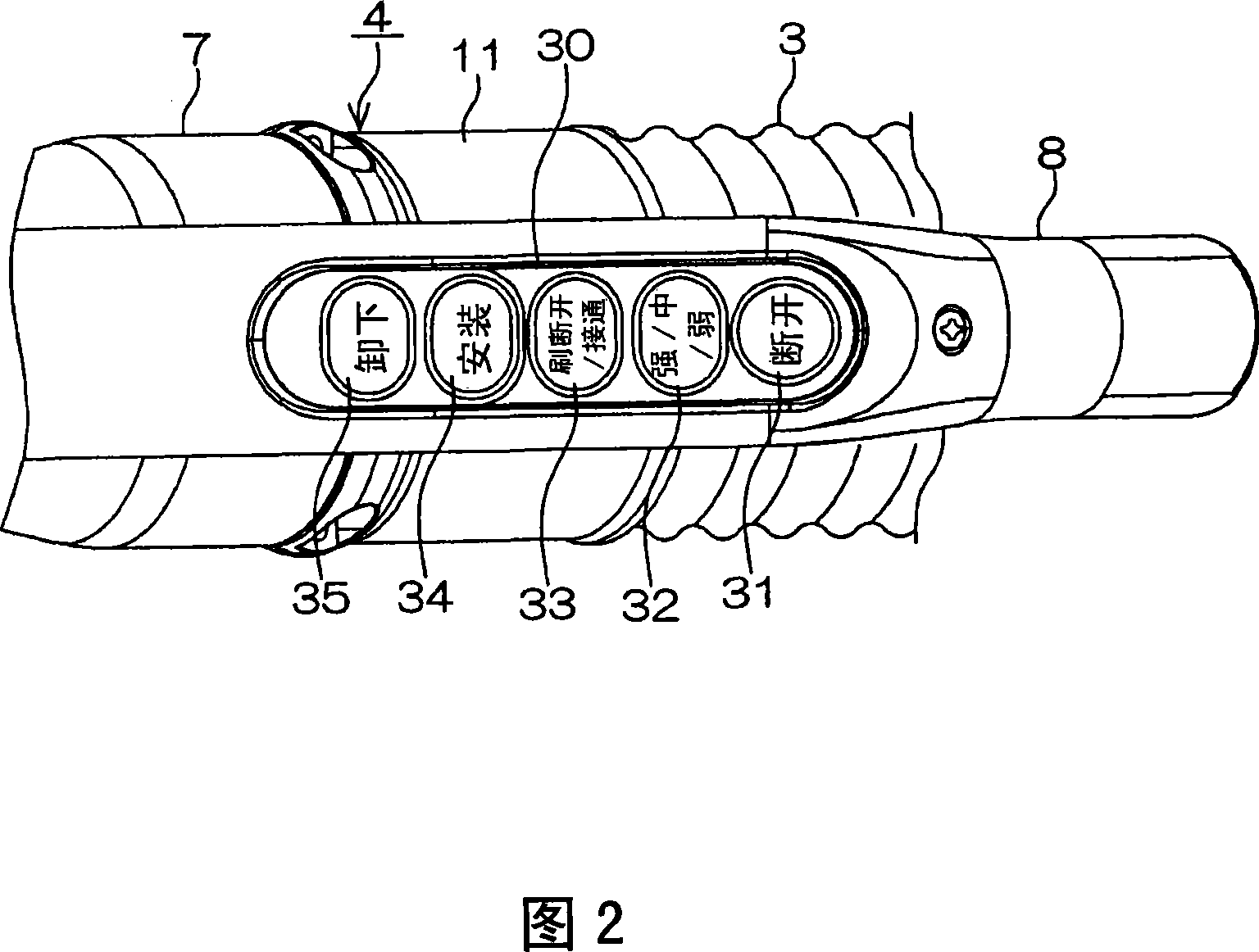

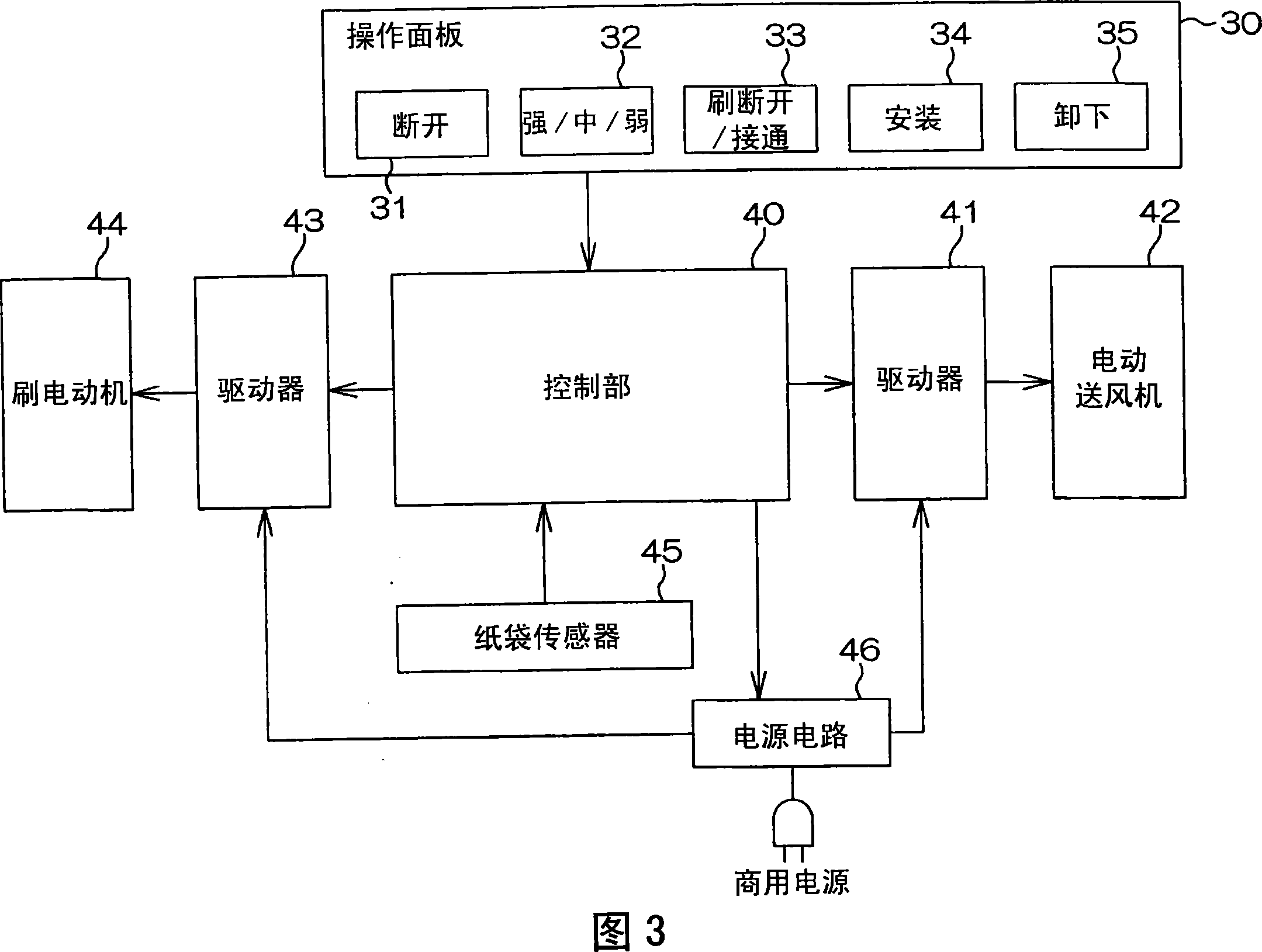

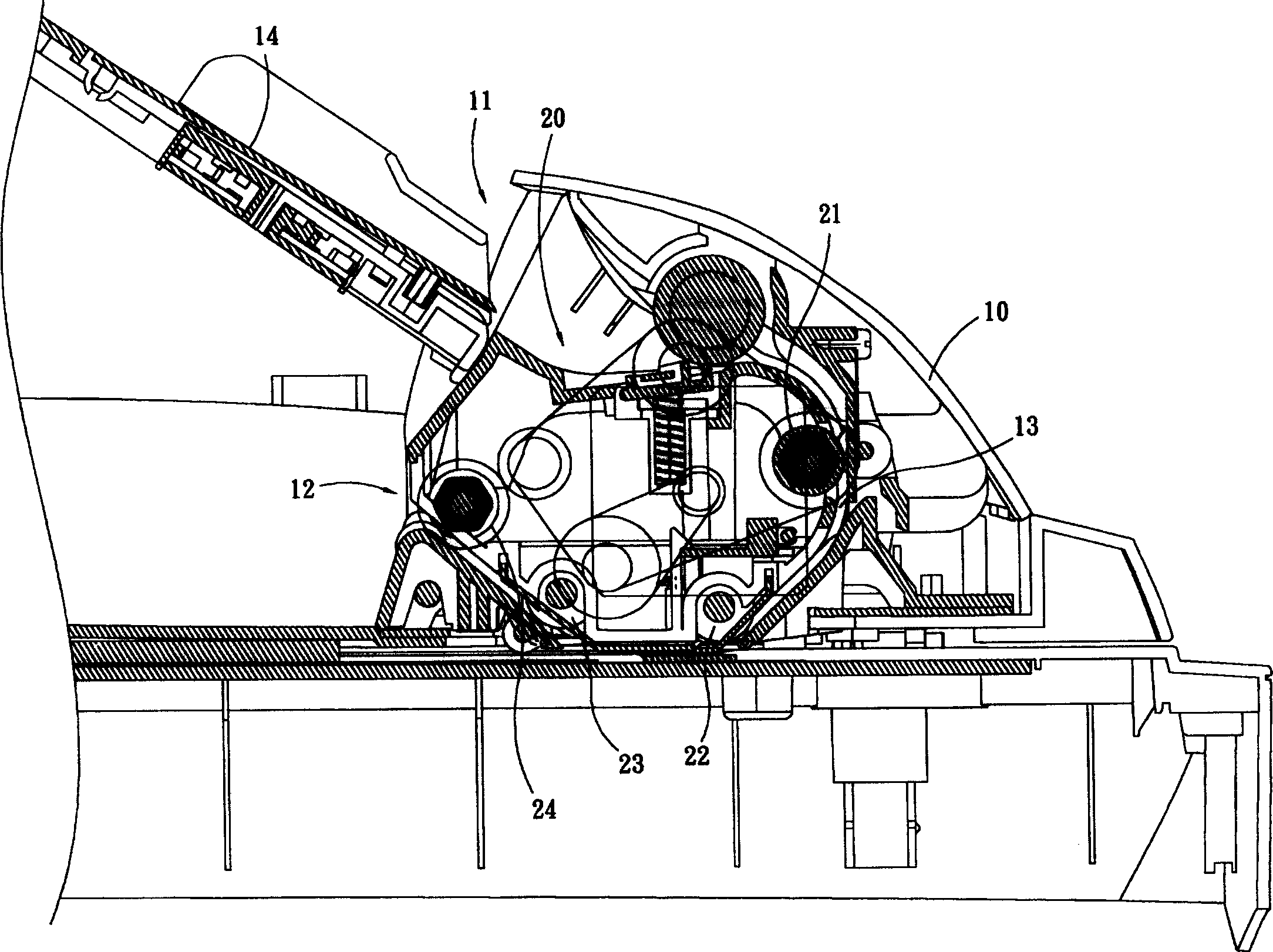

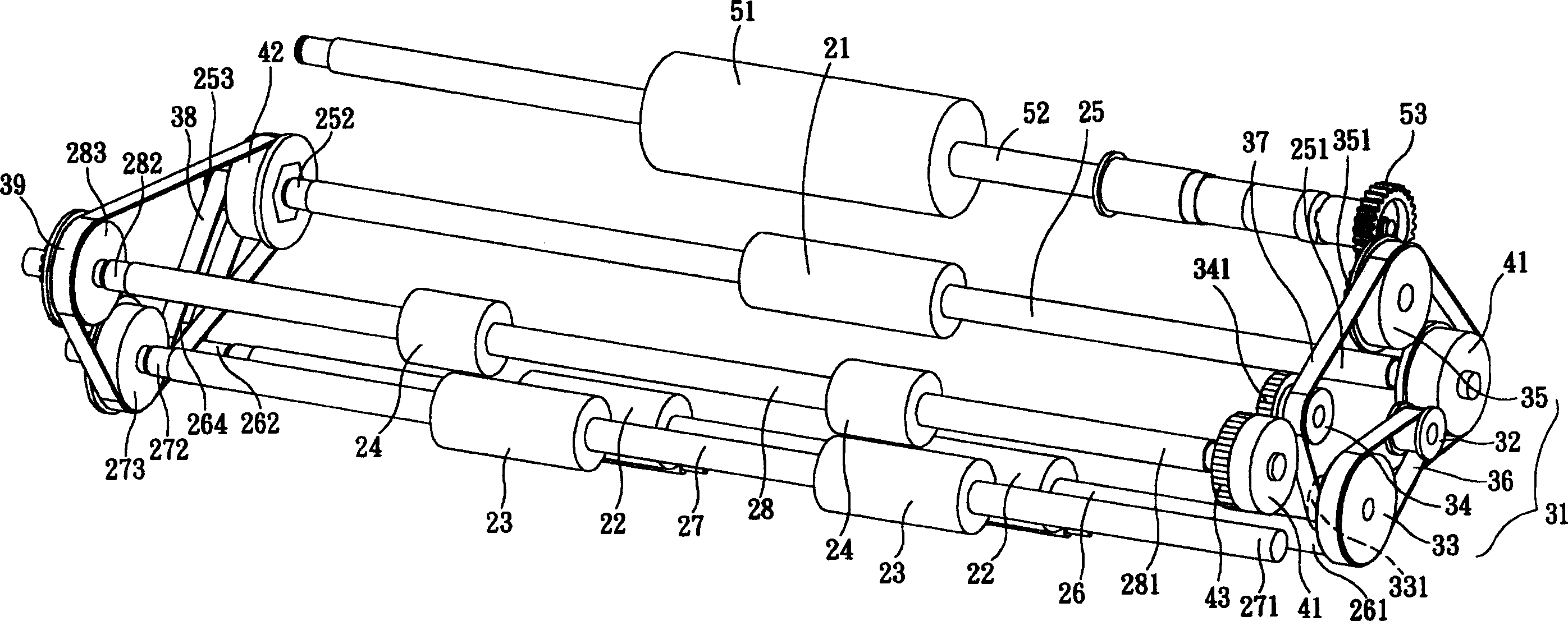

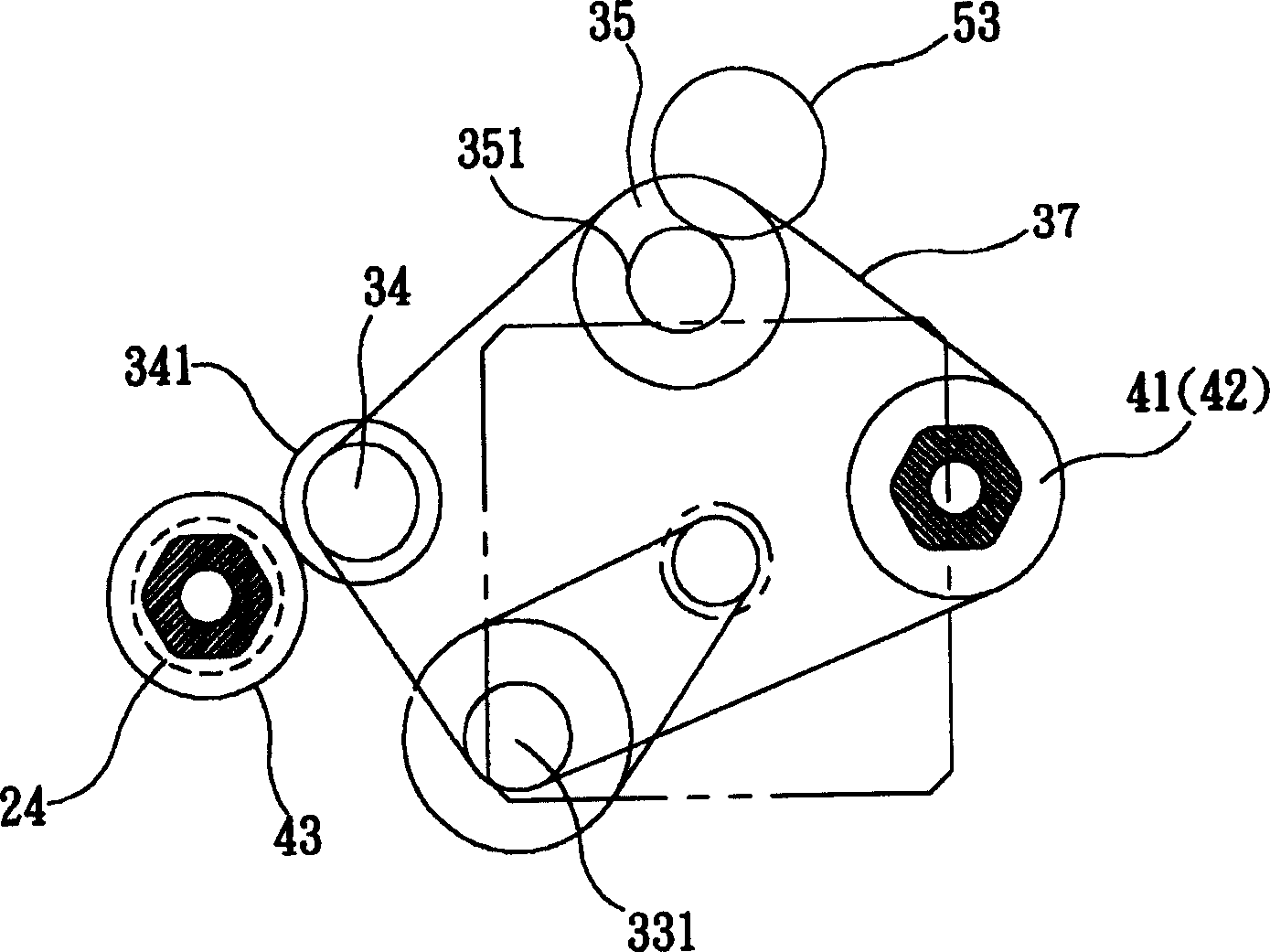

Electric vacuum cleaner

InactiveCN101238961AEasy to operateAutomatically removedSuction nozzlesElectric equipment installationEngineeringVacuum cleaner

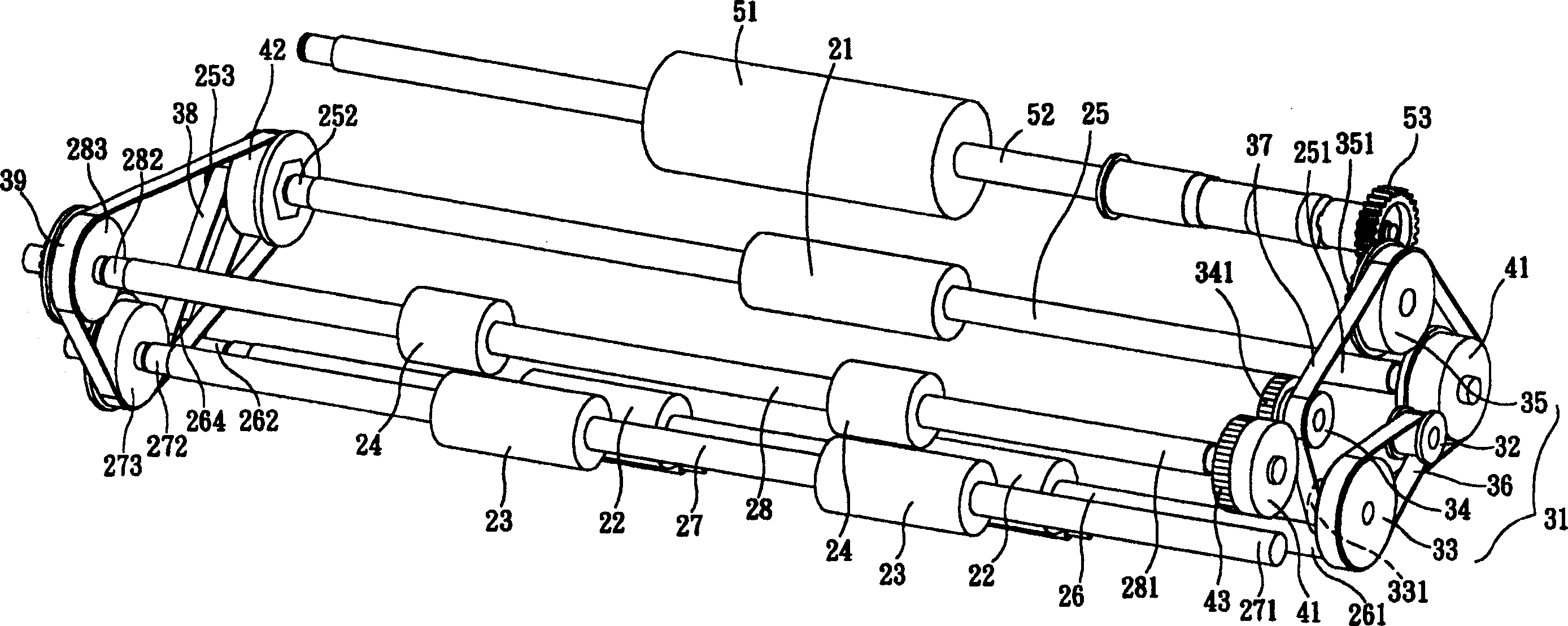

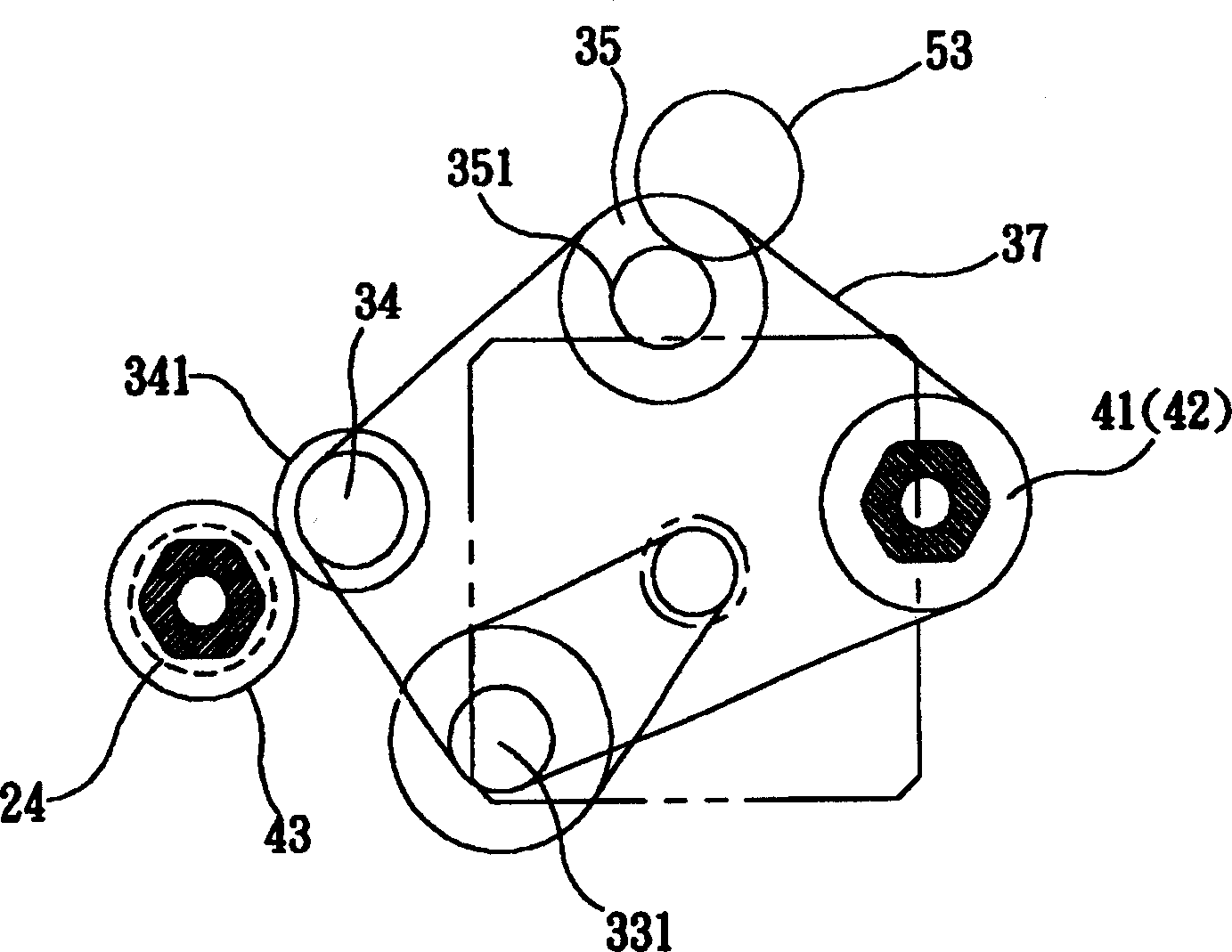

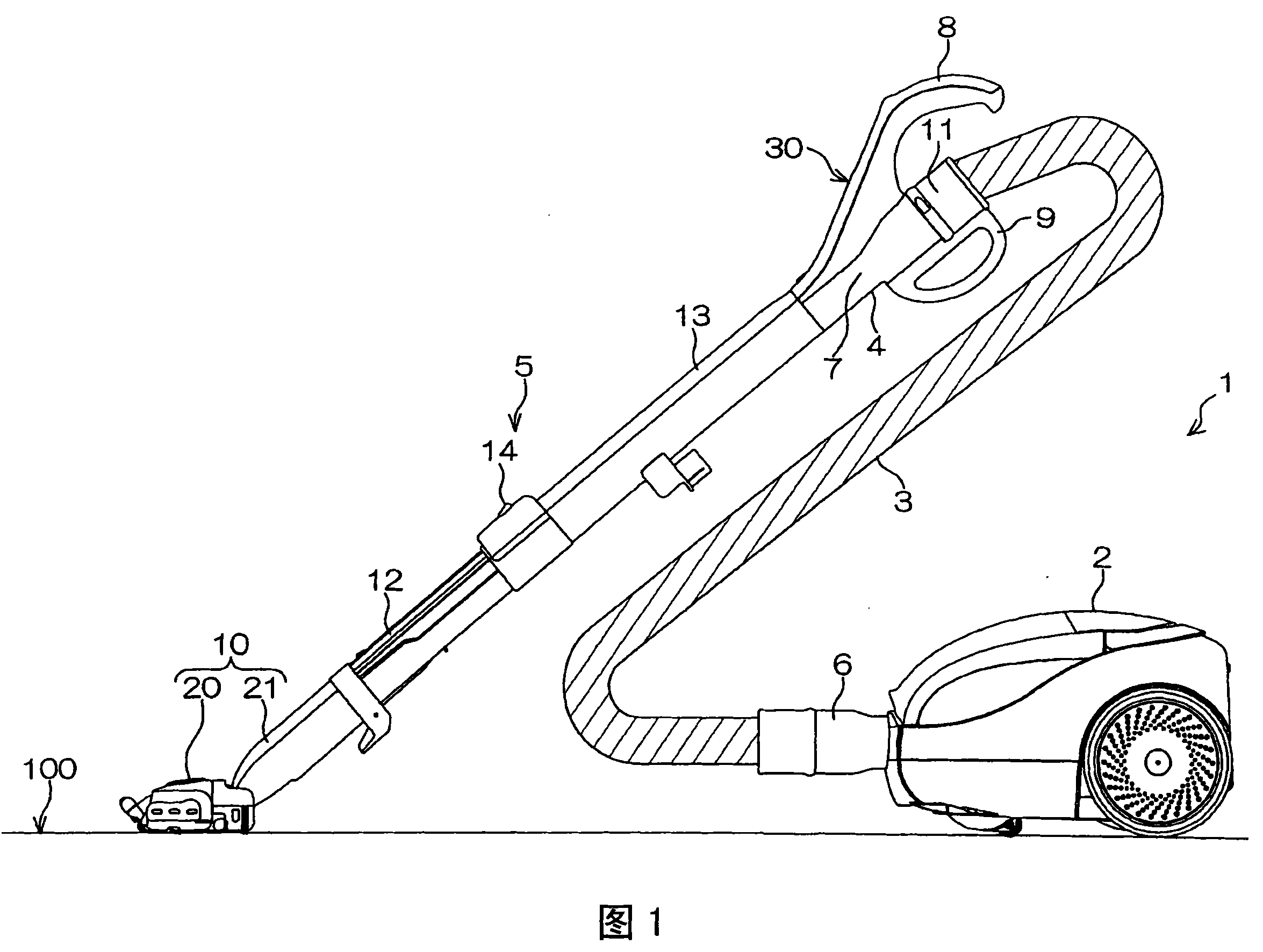

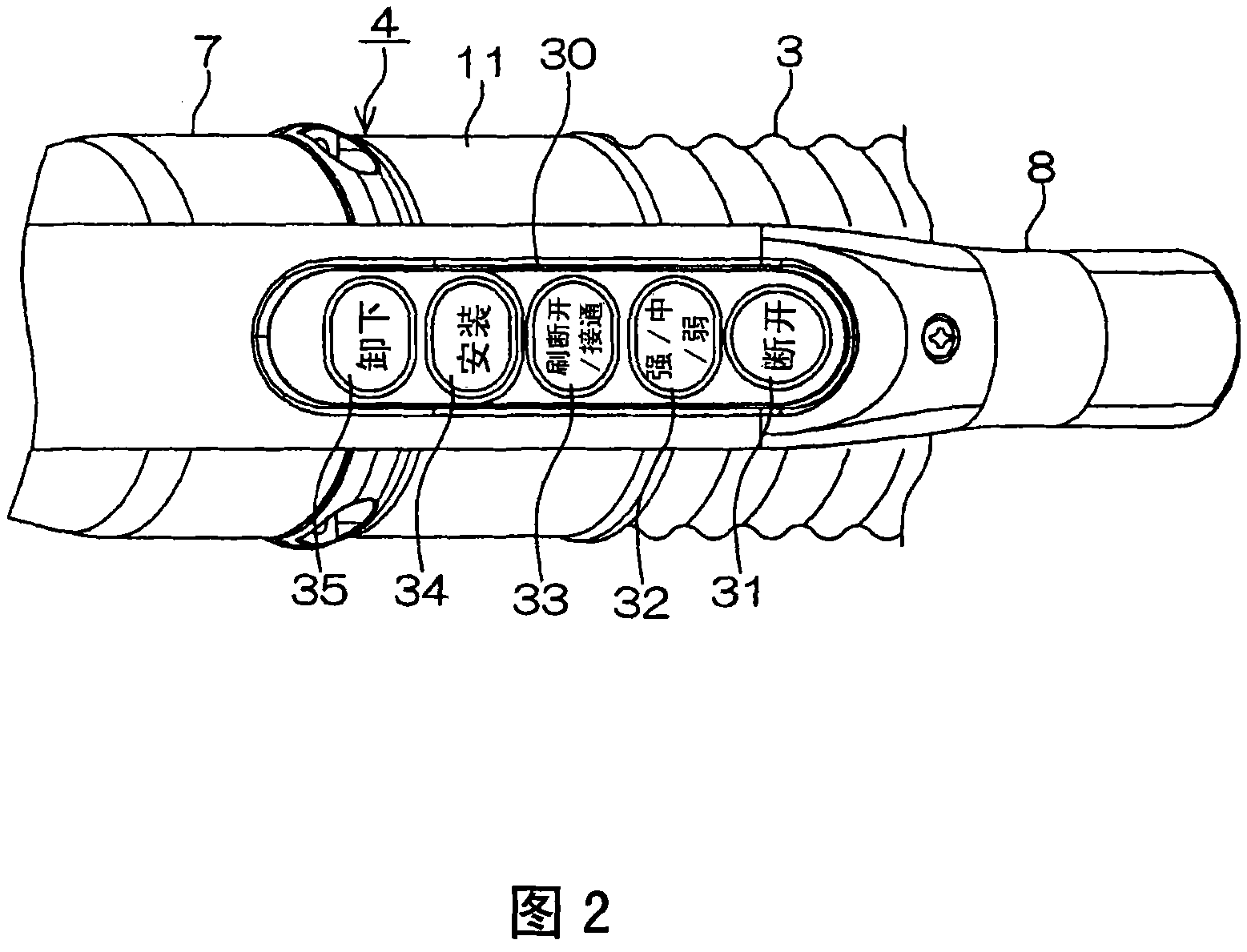

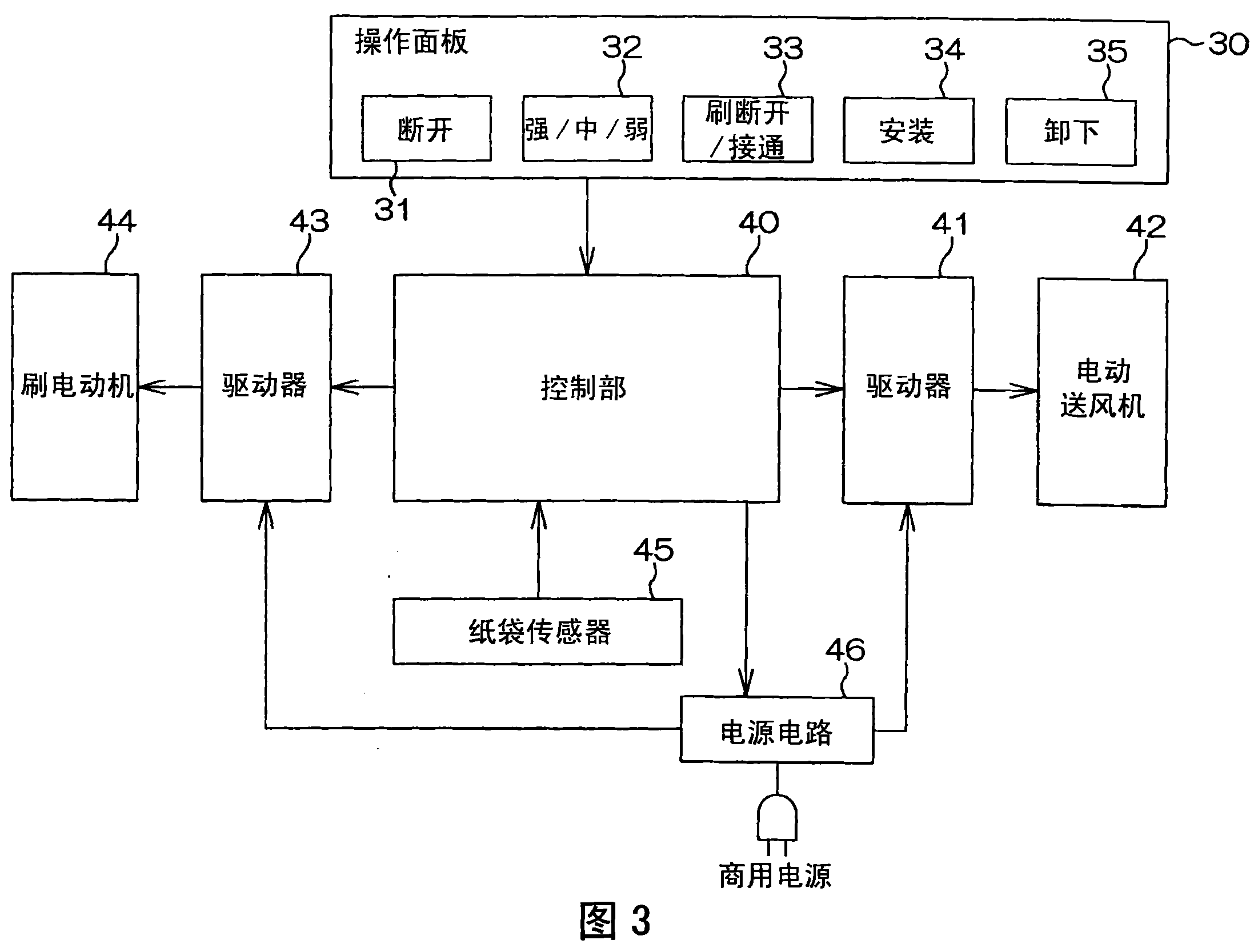

Provided is an electric vacuum cleaner in which a rag is wrapped around an electric brush built in an inhalation appliance for wiping and cleaning, which is advantageous for expanding the use of the electric vacuum cleaner. In order to wrap the rag (50) around the rotating brush (25), the rotating brush (25) can be rotated in a predetermined direction at a predetermined rotational speed by a brush motor (44). In addition, in order to remove the rag (50) wrapped around the rotating brush (25), the rotating brush (25) is repeatedly rotated forward / reversely. The suction force of the electric vacuum cleaner is strengthened so that the mop is automatically released by the suction force of the electric blower. According to the present invention, it is possible to provide an electric vacuum cleaner that can remove the rag (50) wrapped around the peripheral surface of the rotating brush (25) without touching it by the user, and is excellent in usability.

Owner:SANYO ELECTRIC CO LTD

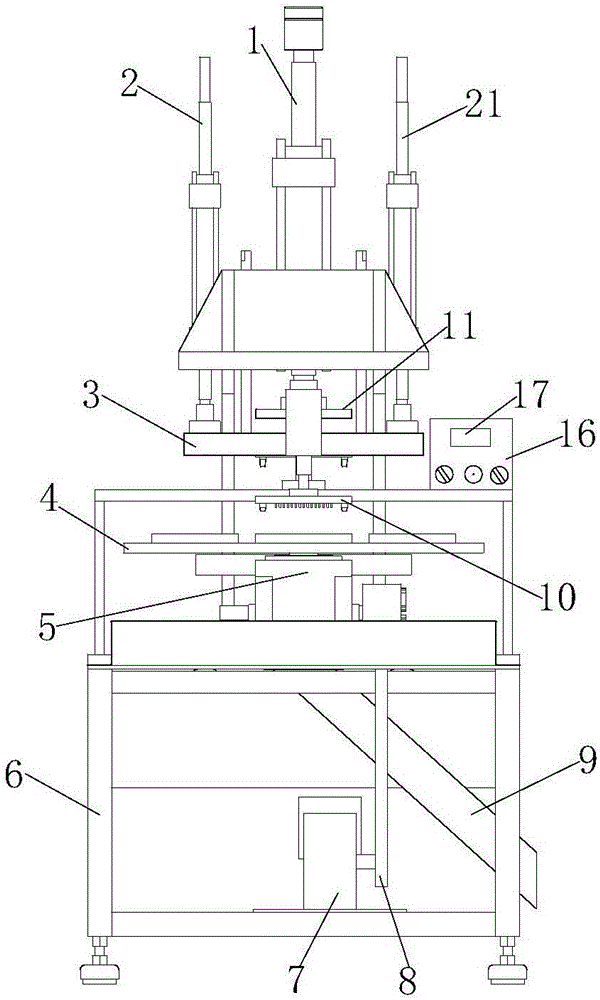

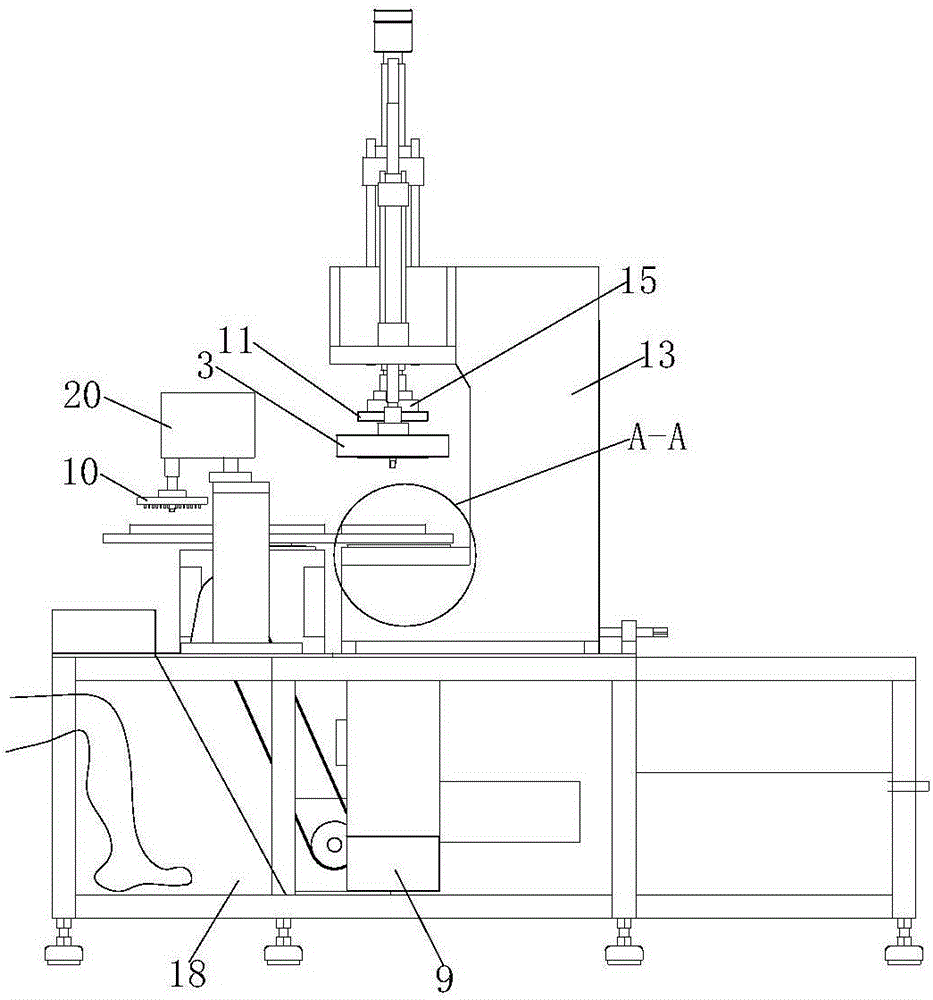

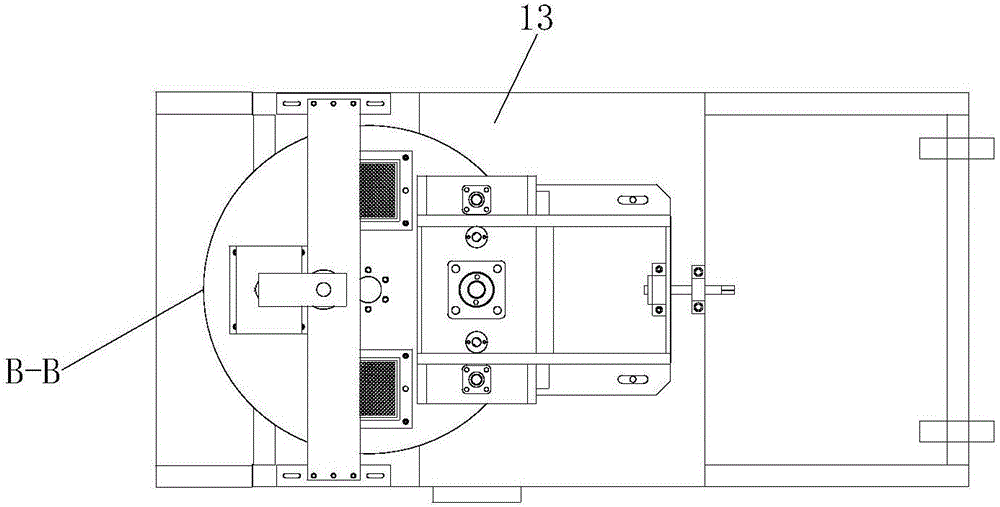

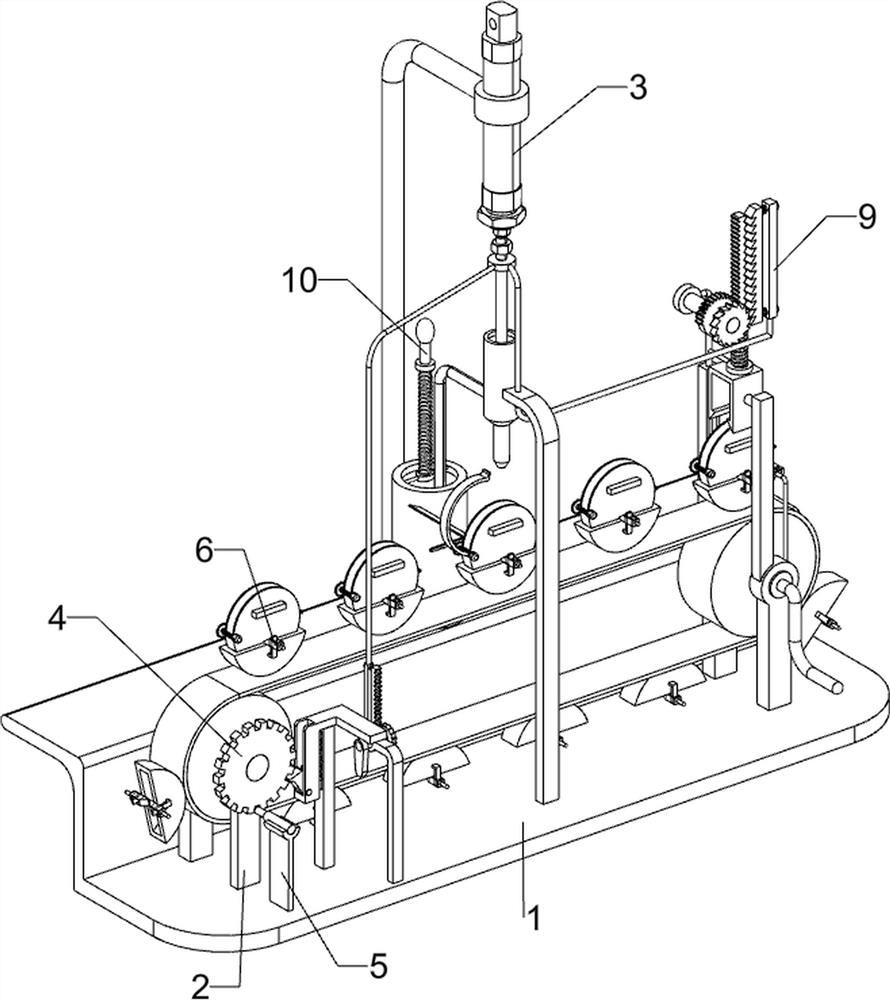

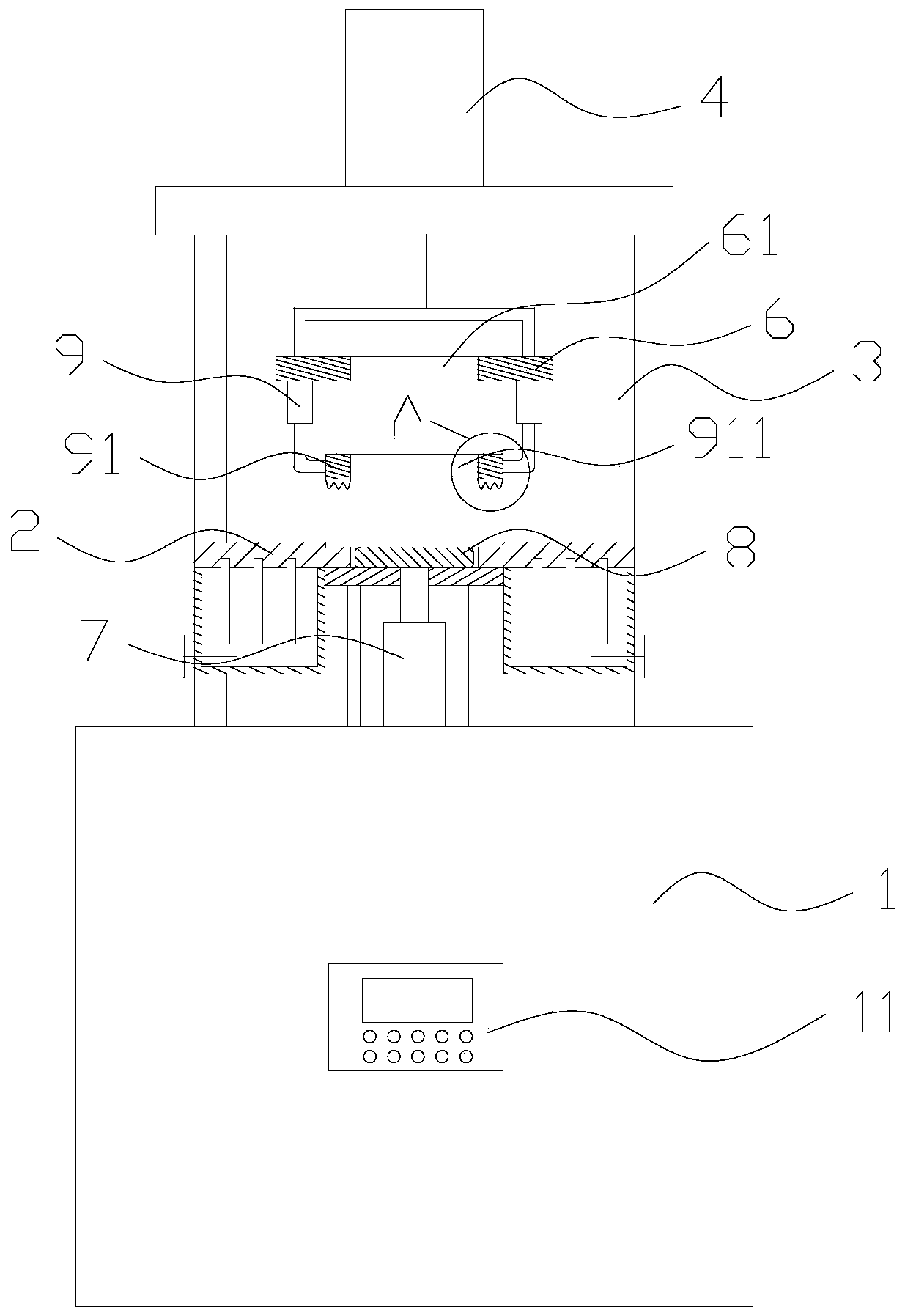

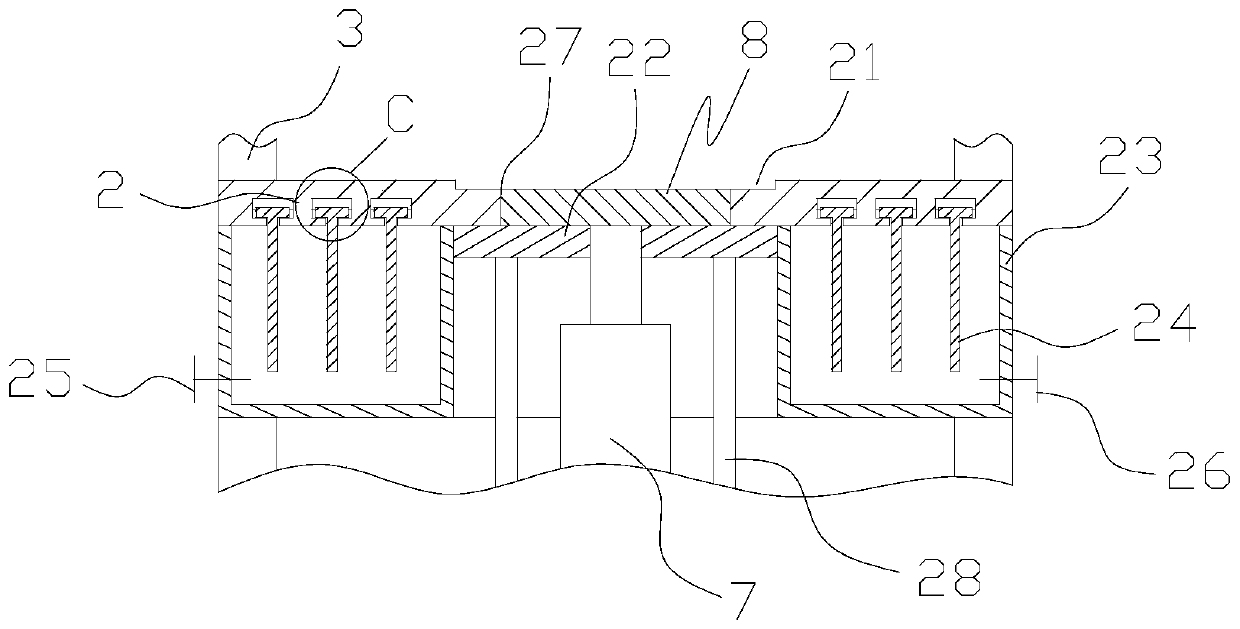

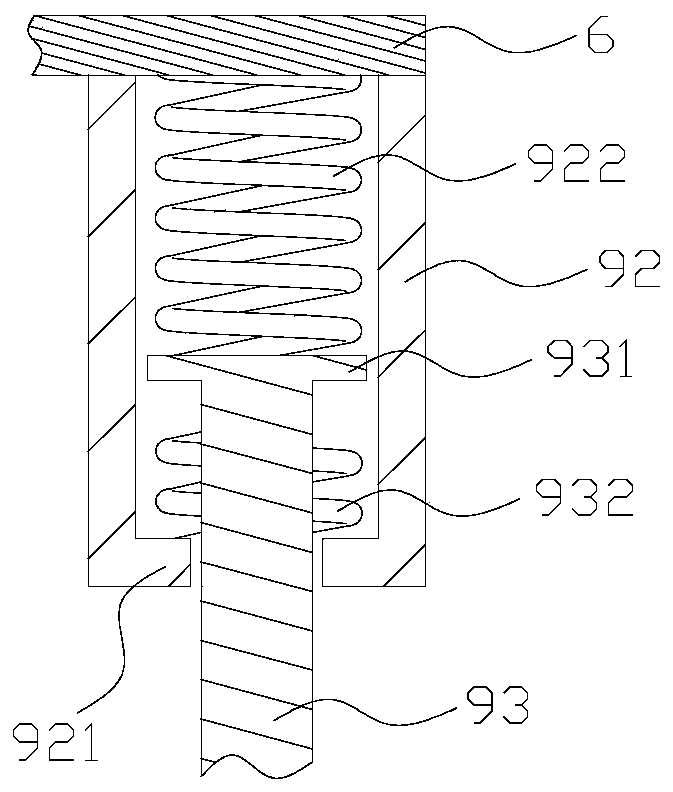

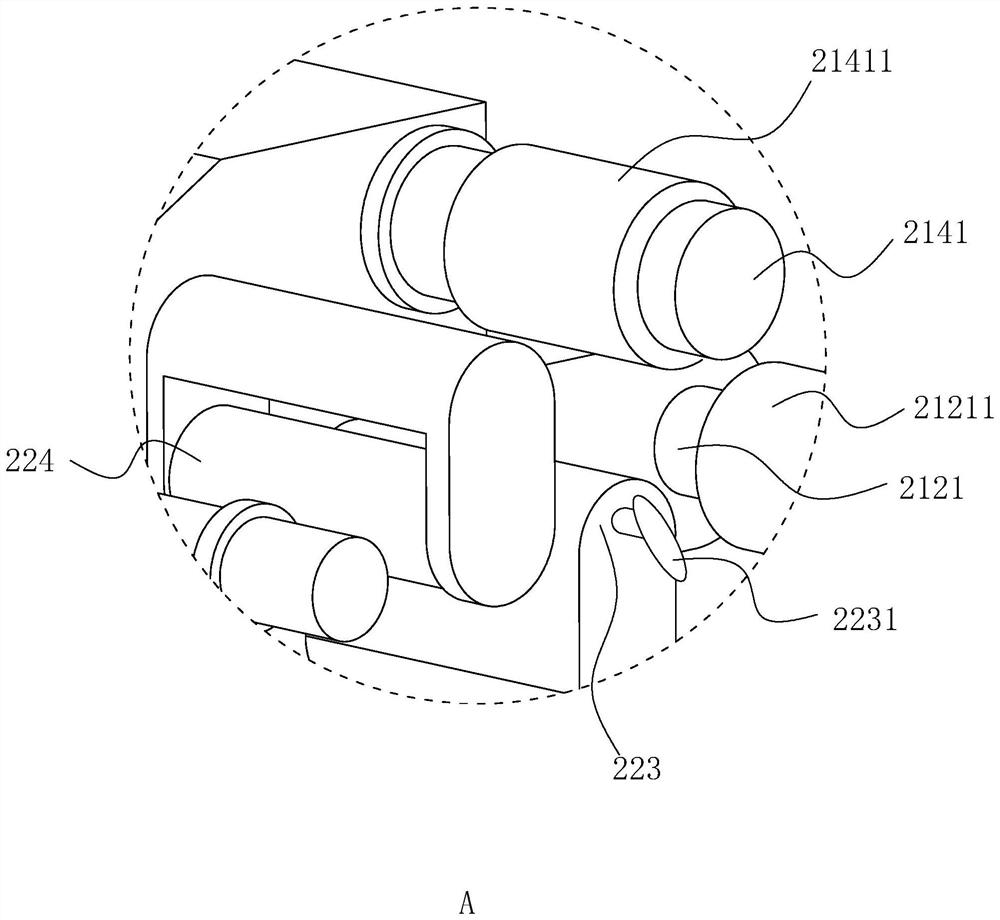

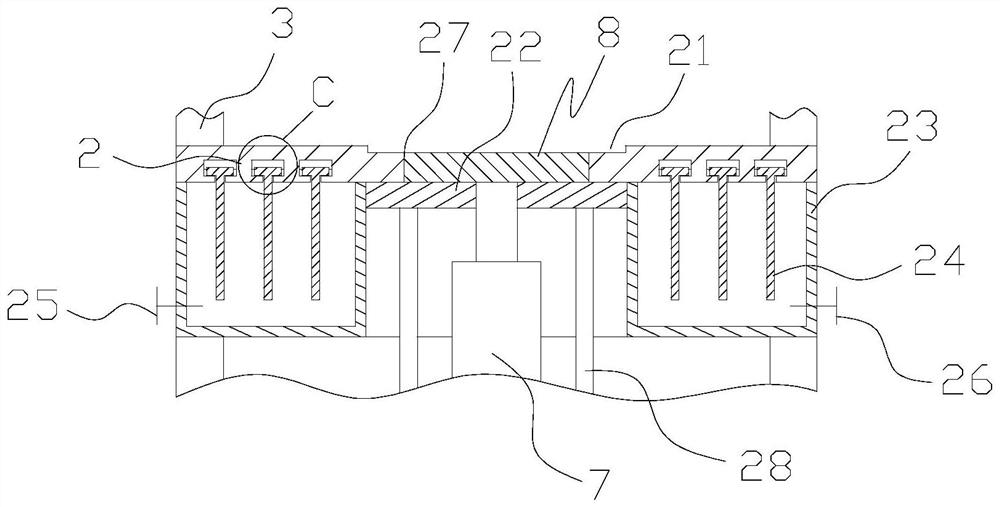

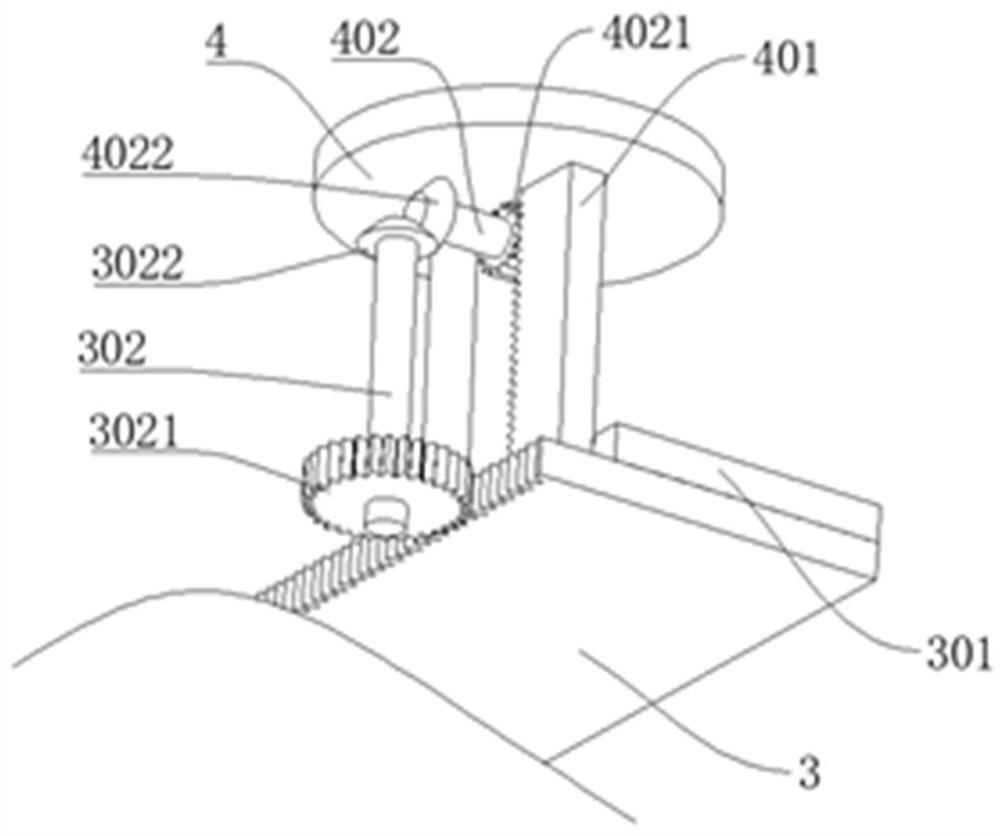

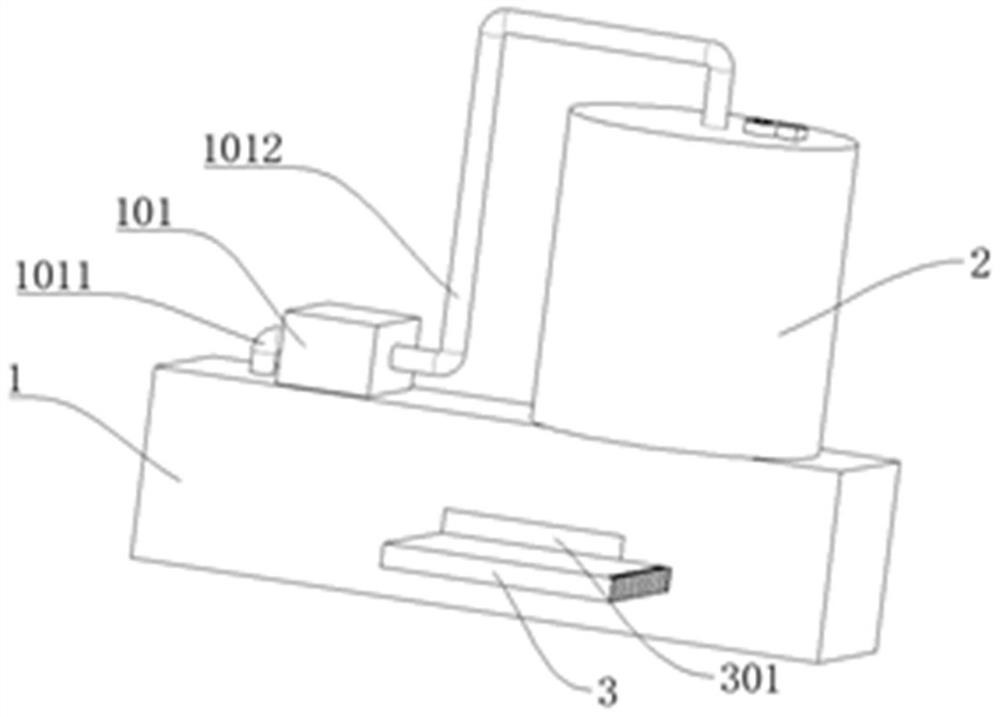

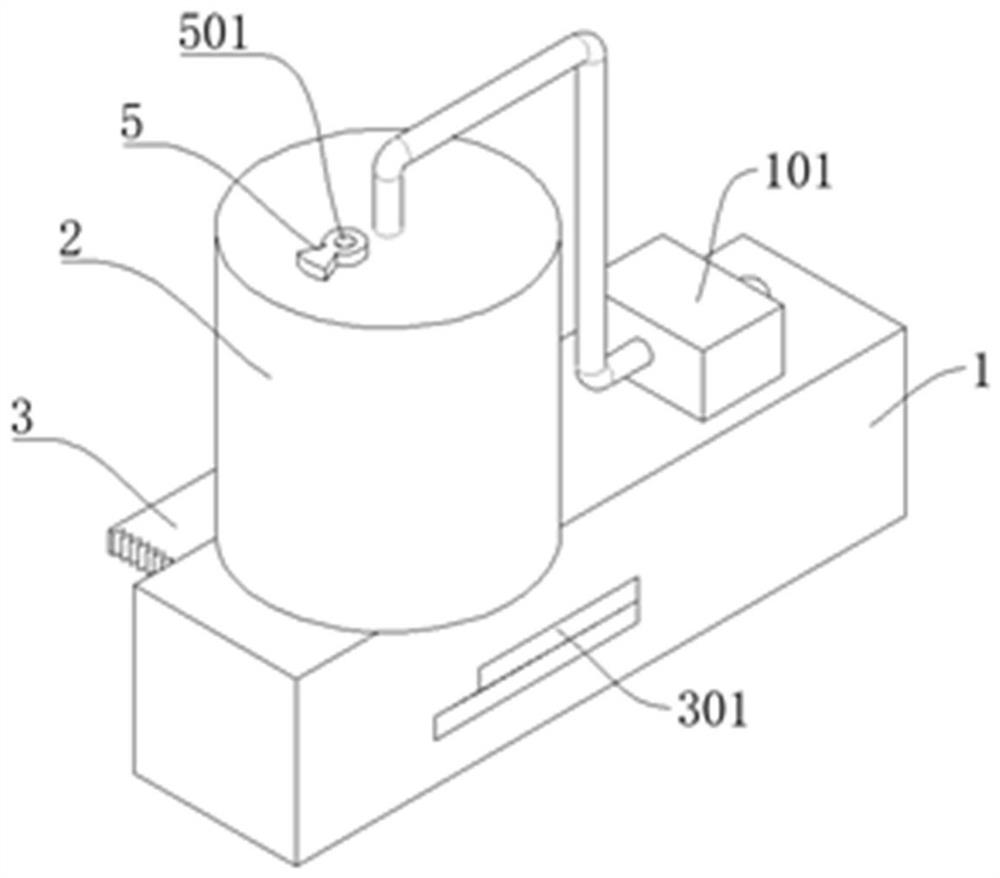

Multi-station rotating disc type force measuring type hydraulic machine

InactiveCN106694671AReduce harmAvoid harmMetal-working feeding devicesShaping safety devicesPunchingEngineering

The invention discloses a multi-station rotating disc type force measuring type hydraulic machine. The multi-station rotating disc type force measuring type hydraulic machine comprises a host body, a large oil cylinder is arranged on the host body, a punching plate is fixedly connected to the bottom of the large oil cylinder, a middle plate is fixedly connected to the bottom of a first small oil cylinder and the bottom of a second small oil cylinder, a worktable rotating disc is arranged below the middle plate, mold products are arranged on the worktable rotating disc, a blanking groove is formed in one side of the worktable rotating disc, and an electric motor is arranged in a rack, and is connected with the worktable rotating disc through a synchronous belt. According to the multi-station rotating disc type force measuring type hydraulic machine, design of the worktable rotating disc can meet multi-station multi-working-procedure requirements, the simultaneous punching working procedure of manual operation and machine punching is flexible and changeable and can adapt to machining of many mold products, precise machining of the mold products can be achieved, the hurt to the person is avoided, and the beneficial effects that cutting and punching are precise, the products automatically enter and are moved out of an operation table, operation is easy, and work efficiency is high are achieved.

Owner:东莞市金拓机械有限公司

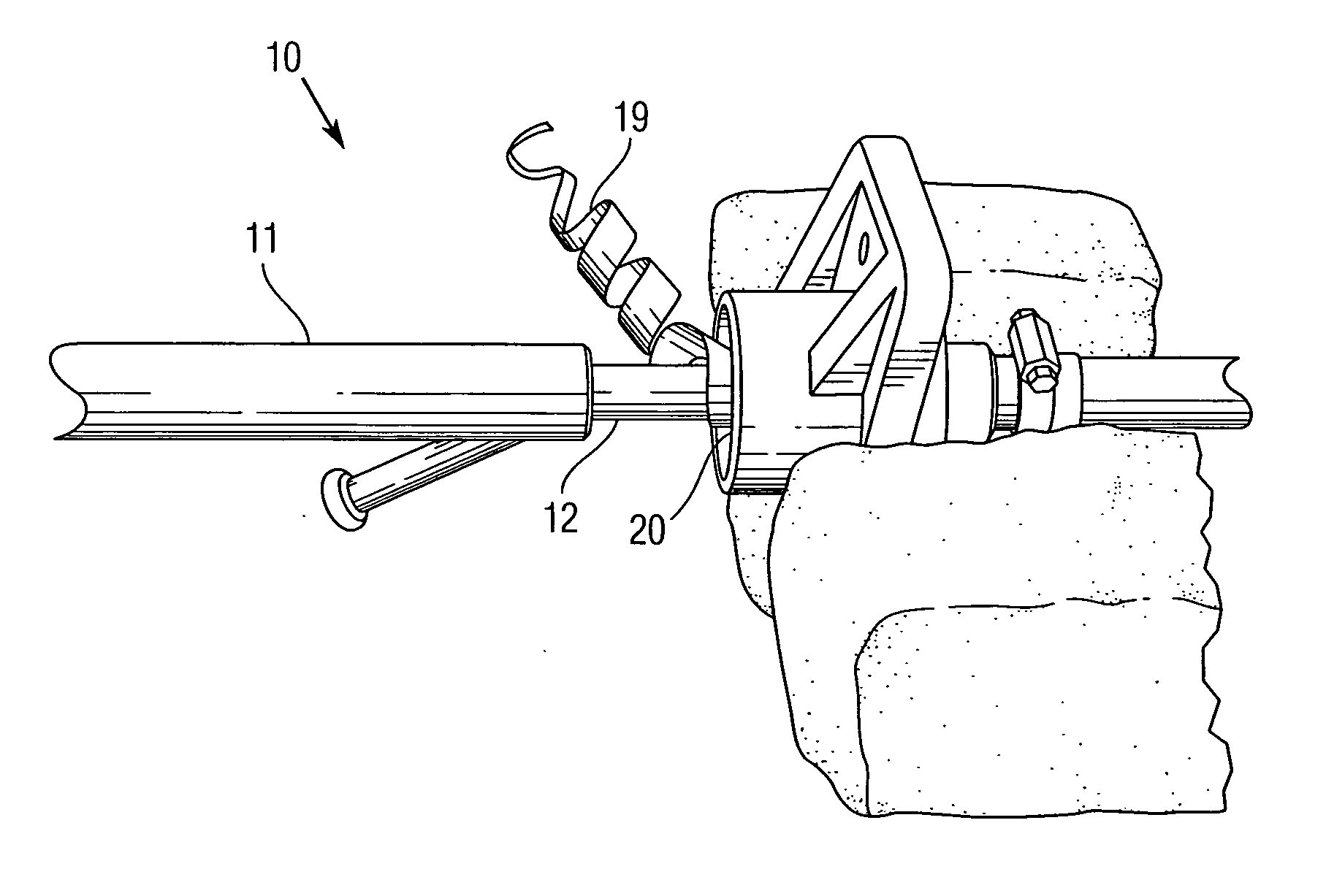

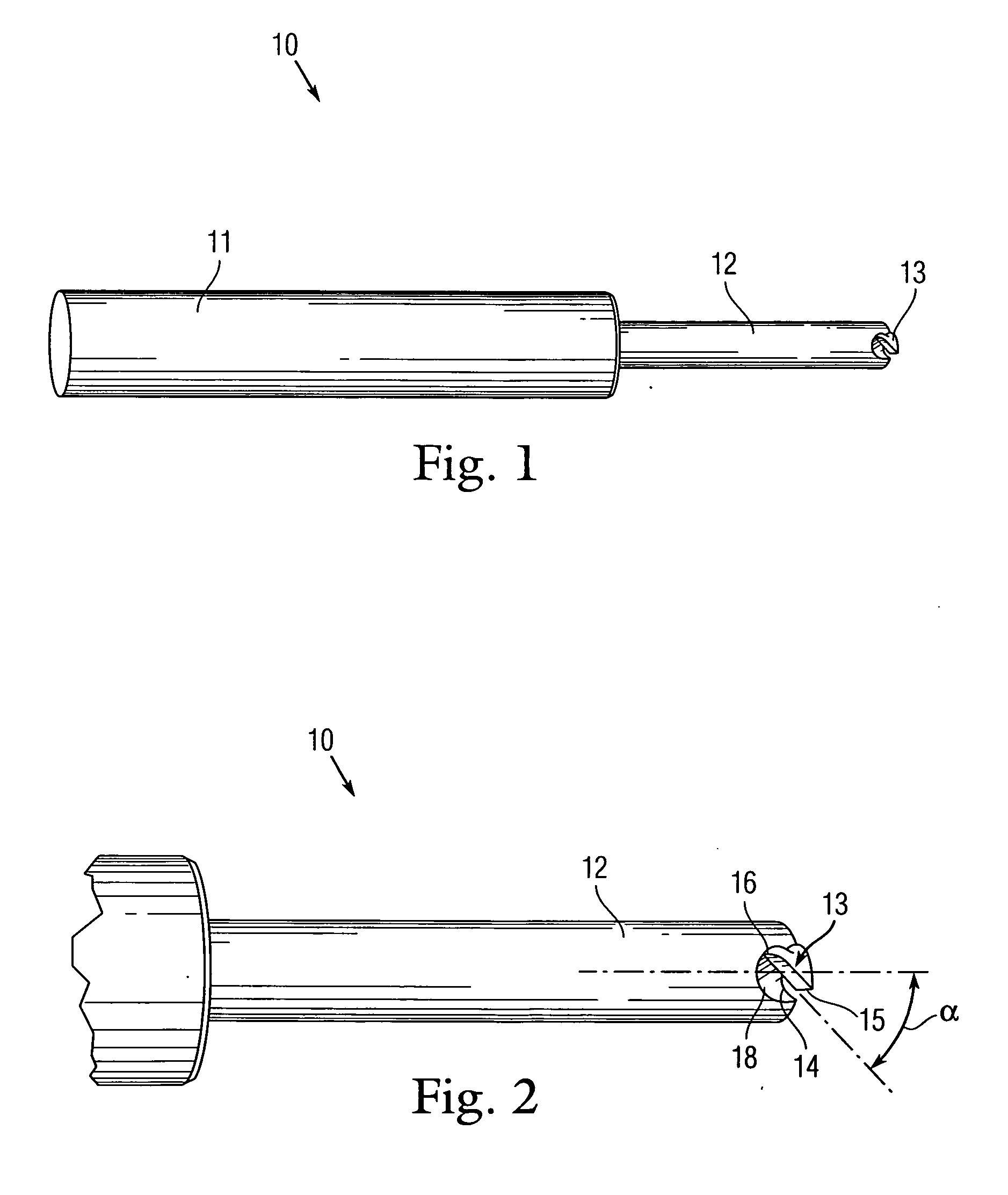

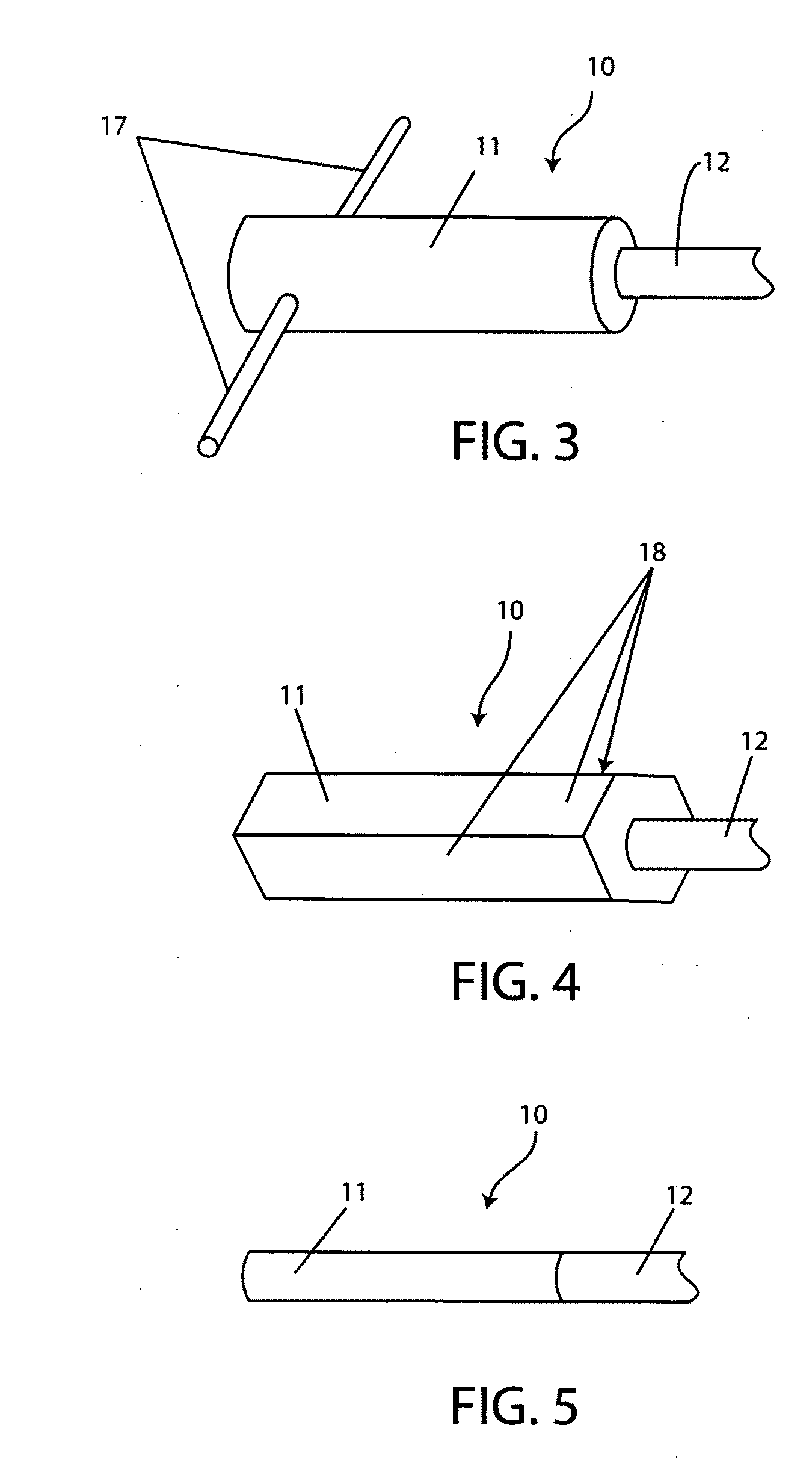

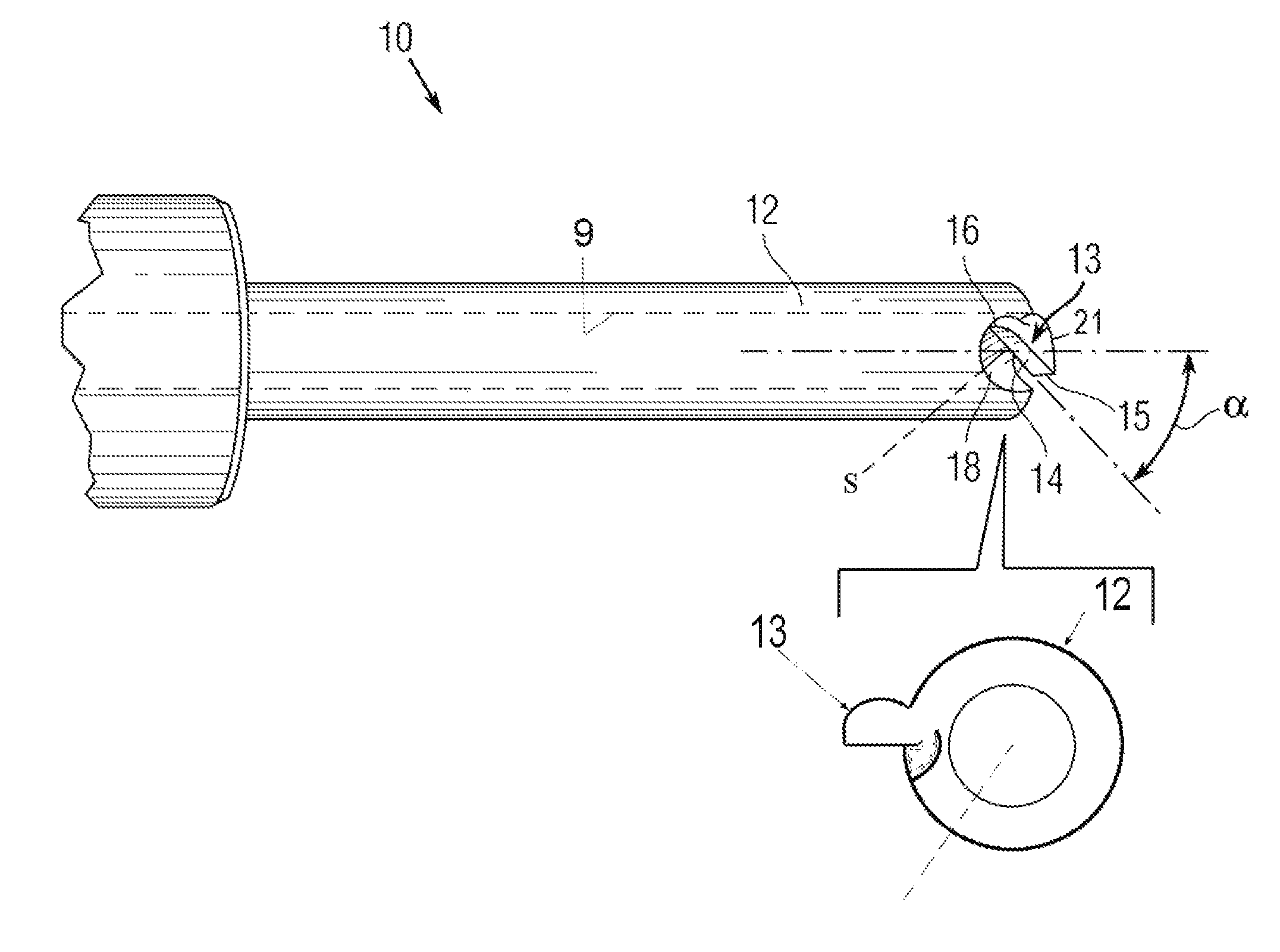

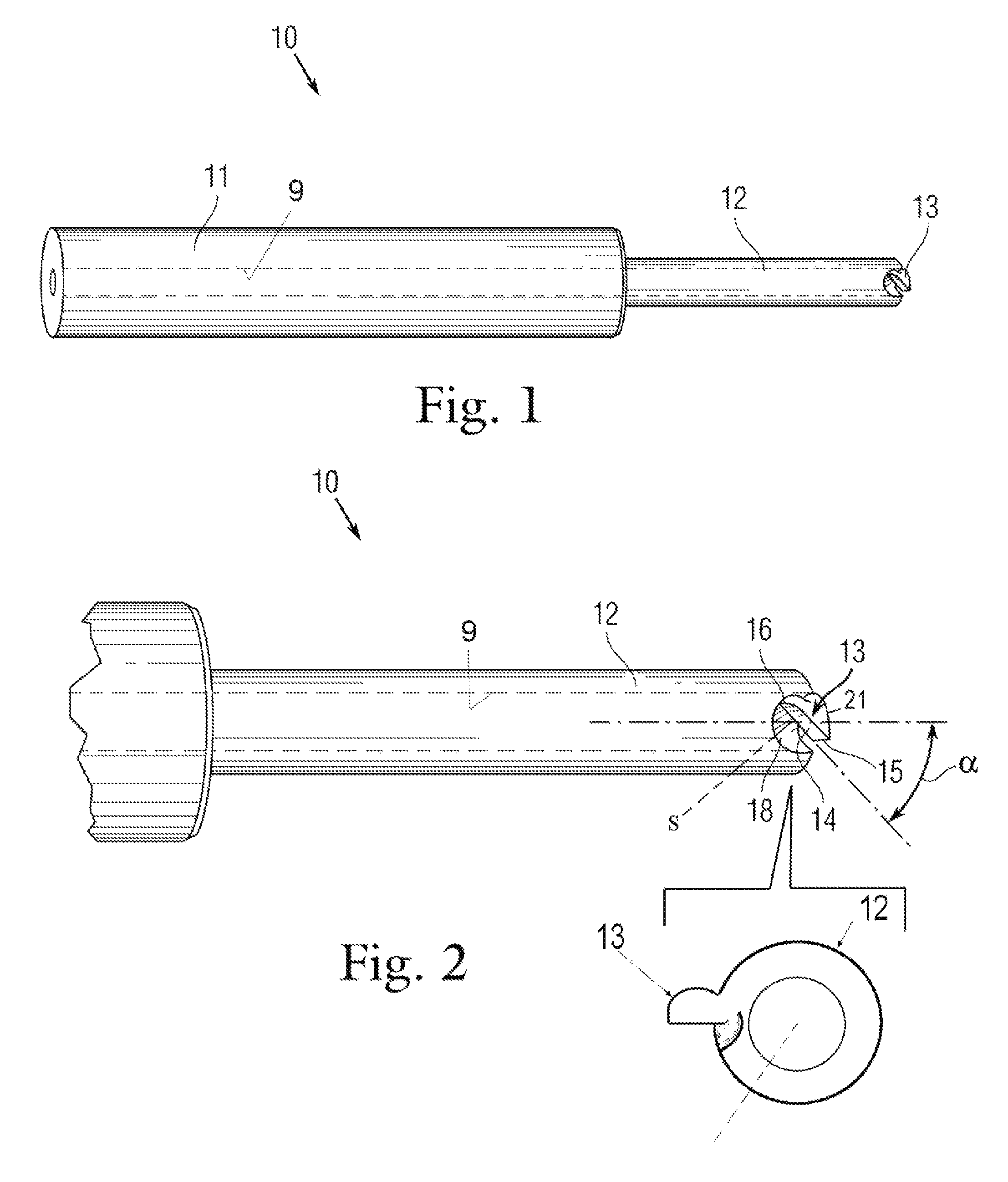

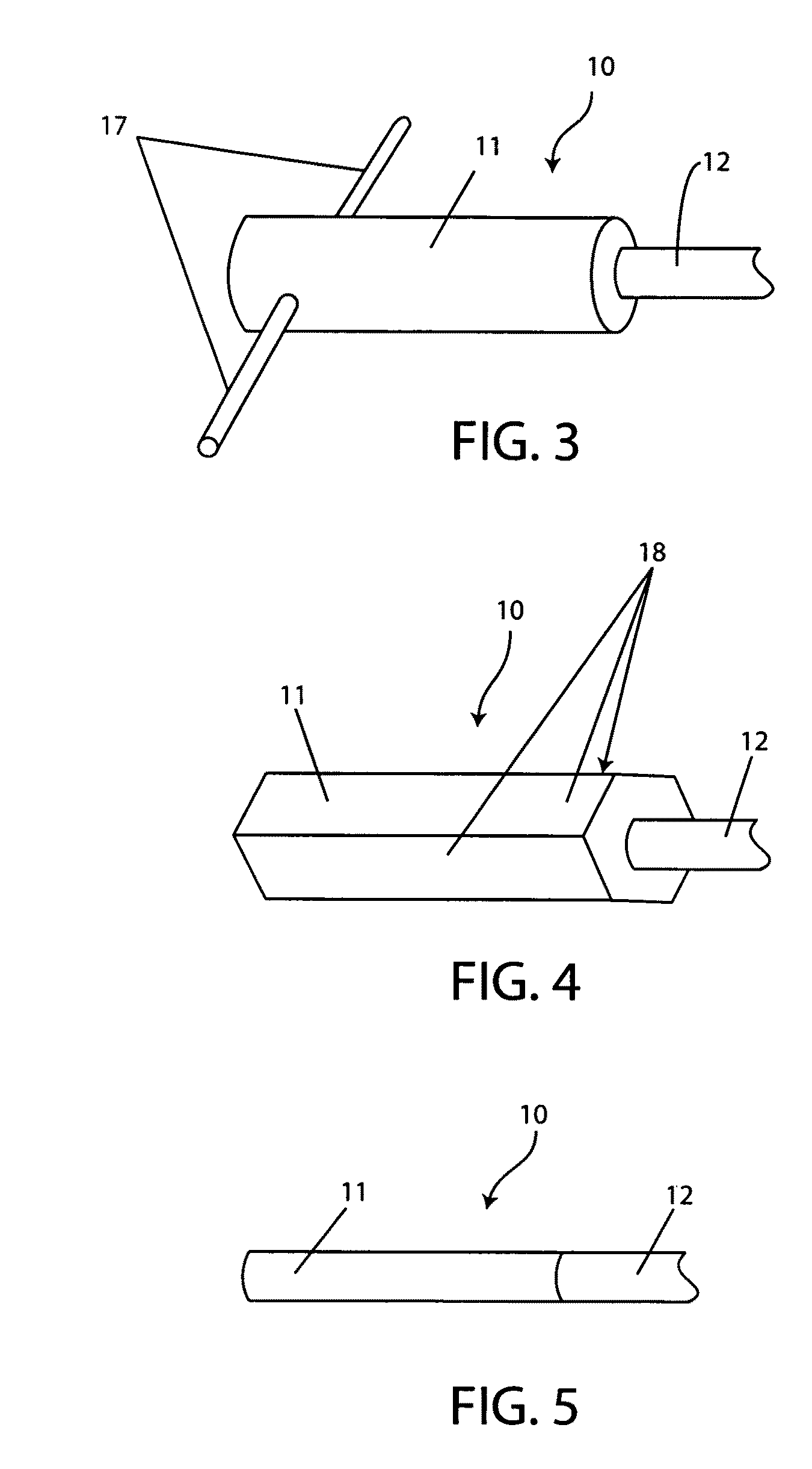

Device for stripping sheathing on unbonded post-tensioning tendons

ActiveUS20100071528A1Smooth rotationDulling it prematurelyMetal working apparatusAnchoring boltsEngineeringKnife blades

A device for helically cutting and automatically removing waste sheathing from the stressing tails of unbonded tendons. The device comprises an elongated body and an attached cutting head. Both the body and the cutting head have a through bore for accepting a post-tensioned tendon. The cutting head comprises an integral blade having a cutting face orthogonal to the cutting head's longitudinal axis and angled between 45 and 85 degrees from the longitudinal axis. The blade cuts the sheathing while also ejecting the waste sheathing.

Owner:VIERECK KYLE +1

Automatic bag grabbing device

InactiveCN105015036AAutomatically removedIncrease the speed of crawlingBox making operationsPaper-makingDrive wheelEngineering

The invention discloses an automatic bag grabbing device which comprises a supporting base, a sleeve support, a baffle support, a swing arm, an oil cylinder, suction cups and suction tubes. The sleeve support and the baffle support are arranged on the supporting base. A sleeve is arranged on the sleeve support. A vertical bag baffle is arranged on the baffle support. A fixing wheel is arranged on the sleeve. The swing arm penetrates the sleeve and is connected with a rotating rod. A rotating shaft is arranged at the other end of the rotating rod in a penetrating manner. A driven wheel is fixedly arranged on the rotating shaft and connected with the fixing wheel through a cog belt. A tensioning wheel is arranged below the cog belt. The two suction cups are arranged on the rotating shaft through two suction cup fixing bases. The suction tubes are connected with the suction cups respectively. The top of the swing arm is connected with the oil cylinder on the supporting base. The rotating rod is driven by the swing arm to be matched with suction of the suction cups, small bag products can be automatically taken down from processing equipment, the grabbing speed is higher, efficiency is higher, and potential safety hazards existing during manual grabbing are avoided.

Owner:SHANGDONG TENOV PESTICIDES

Electric medical medicine bottle collection box

The invention discloses an electric medical medicine bottle collection box, which comprises a barrel body, a through groove is formed on the lower side wall of the barrel body, a lower collection box passes through the through groove and is located in the barrel body, and the lower collection box is located Directly below the barrel, the handle of the lower collection box is inserted into the through groove, and the bottom plate of the upper collection barrel has a plurality of sorting through holes, which are located directly above the lower collecting box; the bottom plate of the barrel body has a horizontal Through the slot, the top of the moving block is fixed on the bottom surface of the lower collecting box, the moving block is located on the bottom surface of the lower collecting box away from the through slot, the bottom of the moving block passes through the horizontal through slot and is screwed into the horizontal adjusting screw, and the horizontal adjustment The two ends of the screw rod are hinged on two vertical support plates. It can collect the medicine bottle in the upper collection barrel, and the water or powder in the medicine bottle will fall into the lower collection box for collection, so that the medicine liquid will not flow out and pollute the environment, and the lower collection box can be automatically removed, which is very convenient convenient.

Owner:FOSHAN JIELAN ROBOT CO LTD

Lens production and injection molding device

ActiveCN112706353AAchieve perfusionImplement rightward transferHollow article cleaningGlass productionEngineeringInjection molding machine

The invention relates to an injection molding device, in particular to a lens production and injection molding device. The lens production and injection molding device provided by the invention is high in pouring efficiency, high in automation degree and convenient to clean. The lens production and injection molding device comprises a base which is provided with a conveying mechanism; and an injection molding mechanism arranged on the base. filling of resin is achieved through the injection molding mechanism, and then rightward conveying of the resin is achieved under cooperation of the conveying mechanism; and by arranging an intermittent moving mechanism, the injection molding mechanism moves upwards, the intermittent moving mechanism operates to drive the conveying mechanism to operate, and therefore intermittent operation of the conveying mechanism can be achieved.

Owner:GUANGZHOU JULONG SPORTS CO LTD

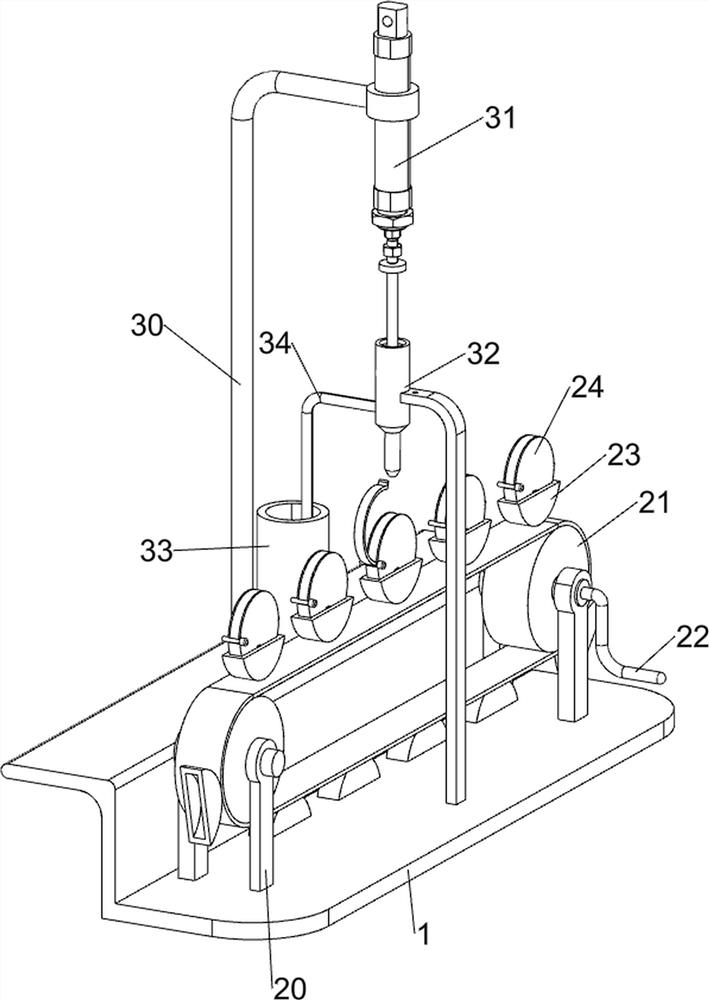

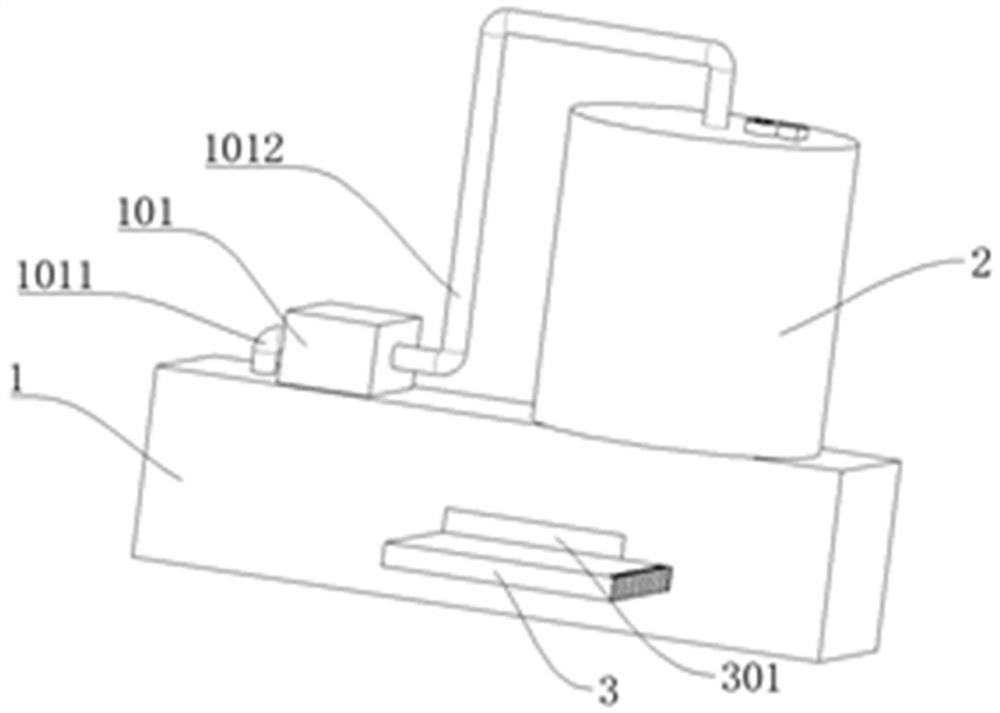

Chemical production equipment and working method thereof

InactiveCN109163516AAutomatically removedDrying solid materialsDrying machines with local agitationEngineeringMechanical engineering

The invention discloses chemical production equipment, comprising a transmission assembly and an oven; the oven is connected with the transmission assembly, wherein the oven comprises a box body whichcomprises a door body; the box body is internally provided with a frame body; the frame body is provided with a multi-layer compartment which is used for placing disk bodies; materials to be dried are loaded in each disk body; the box body is provided with a rear wall; a removing assembly is arranged at the position between the rear wall and the frame body; the removing assembly comprises a lifting unit; a horizontal pushing unit is arranged on the lifting unit; the horizontal pushing unit is used for pushing each disk body placed on the compartment to the transmission assembly. The unattended drying process is realized; when some disk body is dried, the lifting unit moves to a certain height and pushes the disk body out of the box body by the horizontal pushing unit; thus different kindsof materials can be dried in the same box body; and after the time reaches a certain stage, the dried disk body can be removed out automatically.

Owner:东阳市新意工业产品设计有限公司

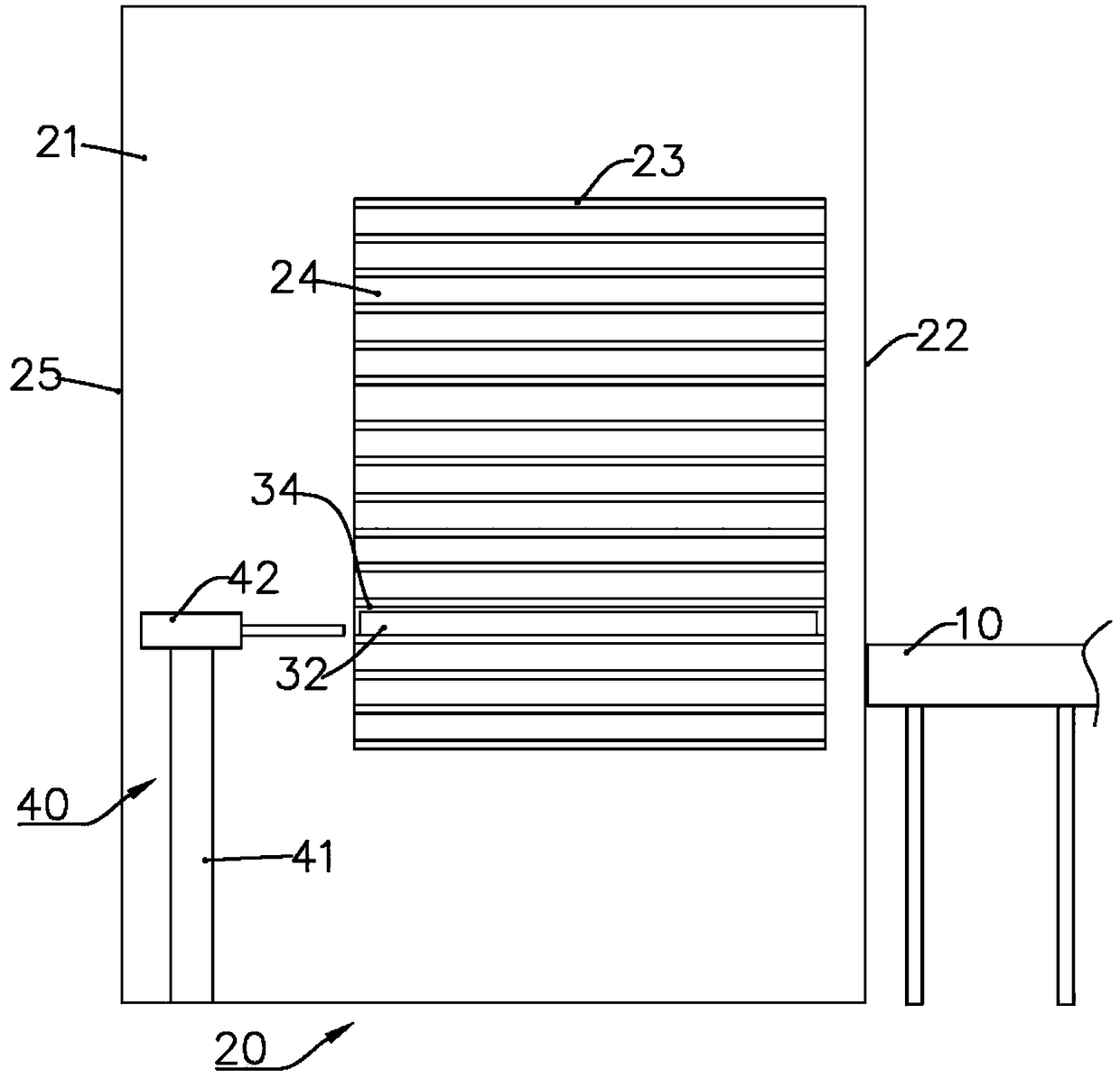

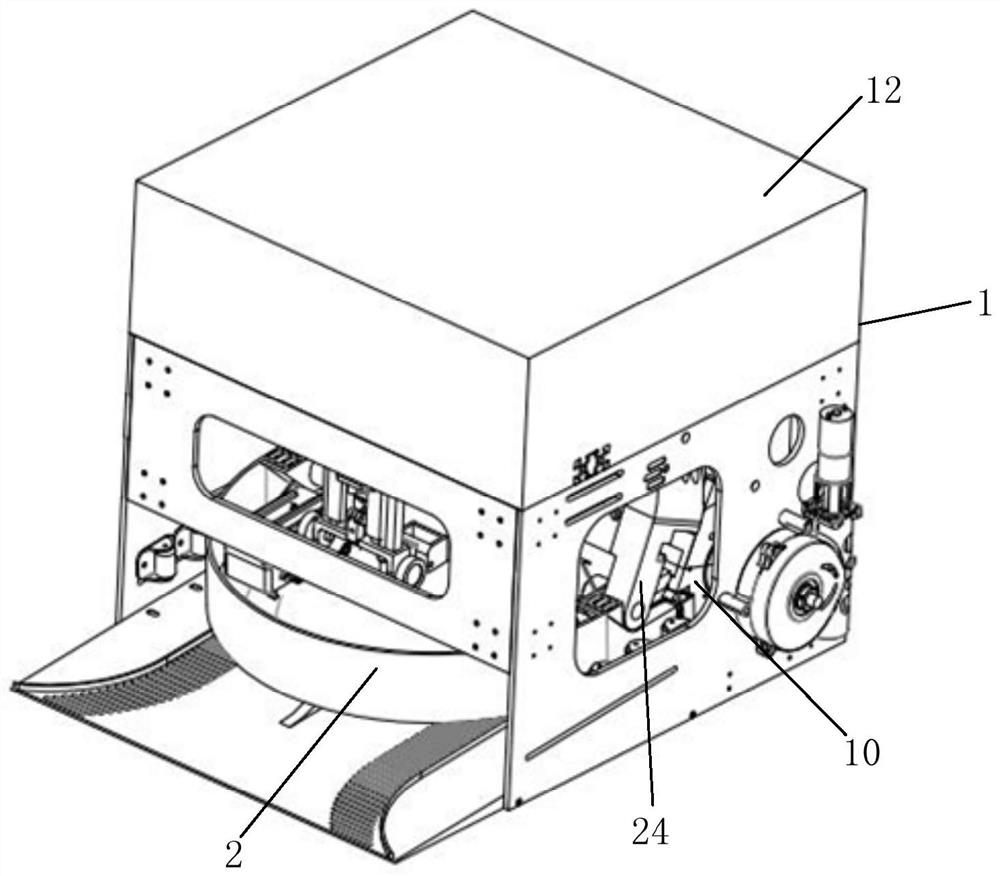

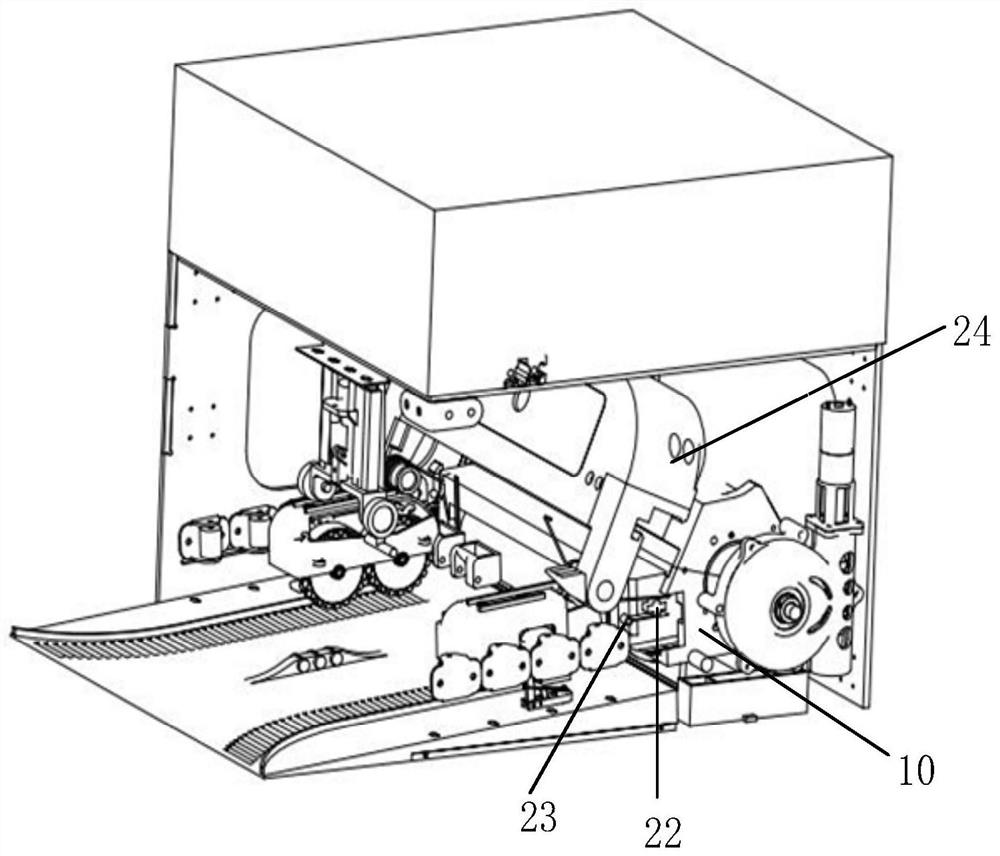

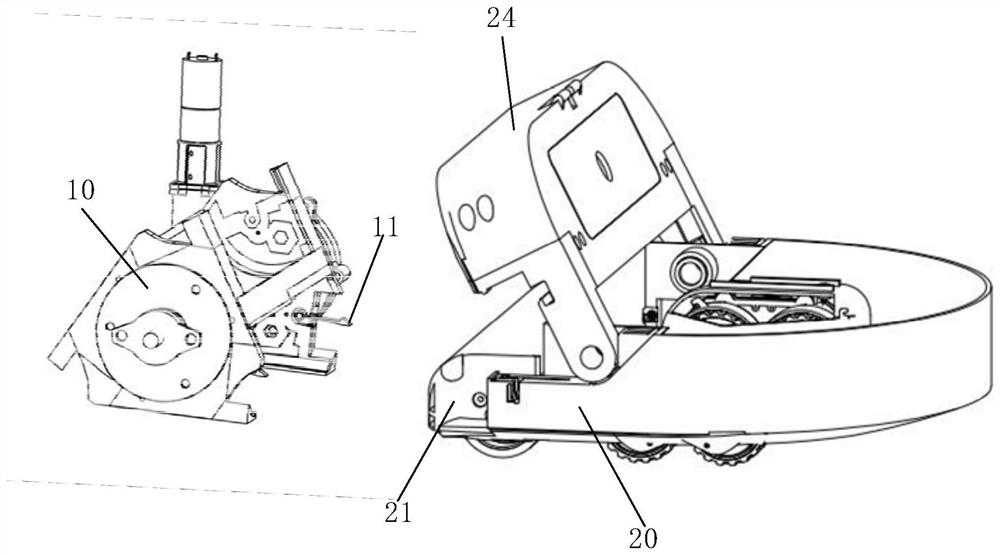

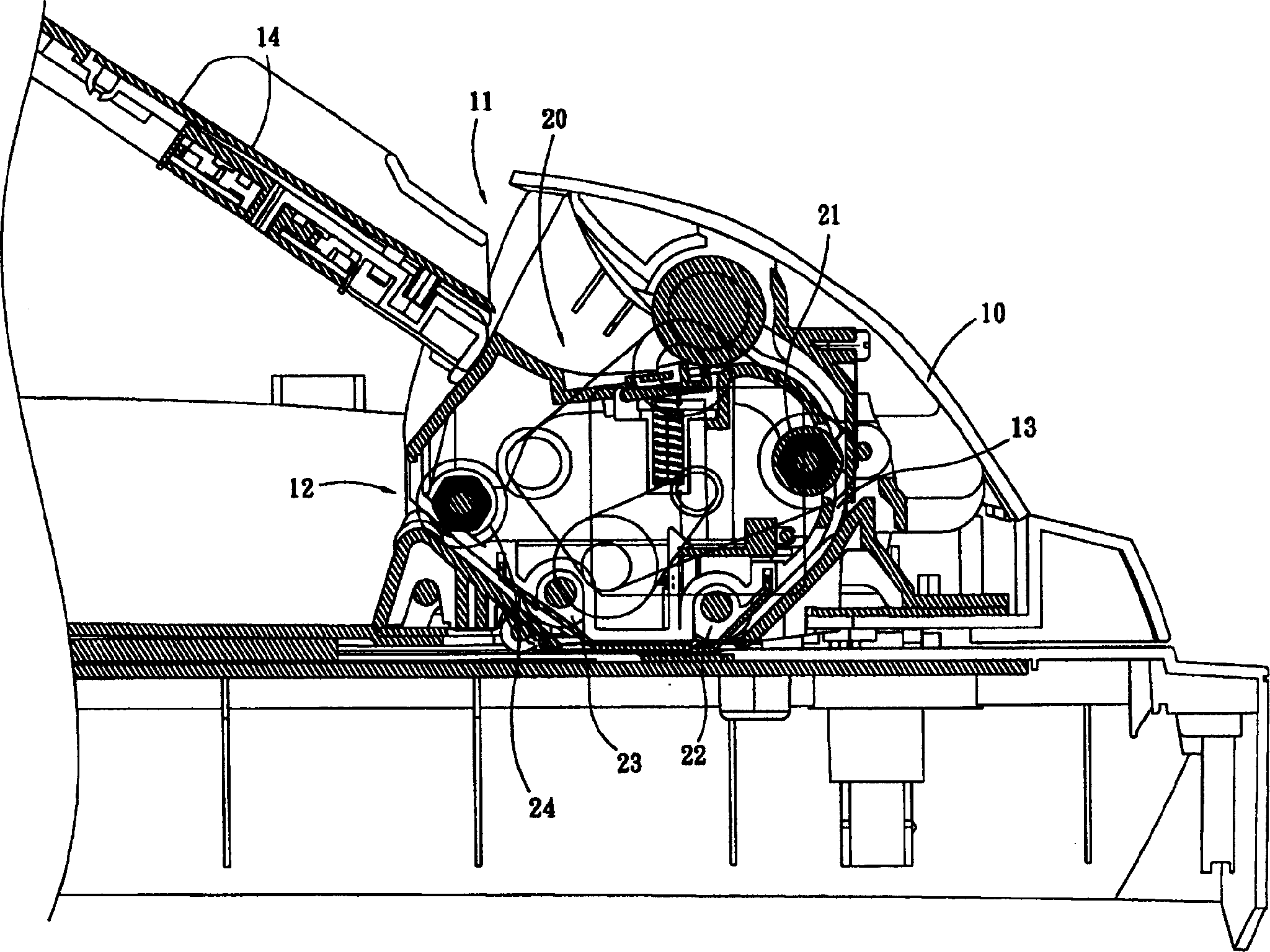

AUtomatic paper feeder with paper feeding and running mechanism

Owner:AVISION PRECISION IND (SUZHOU) CO LTD

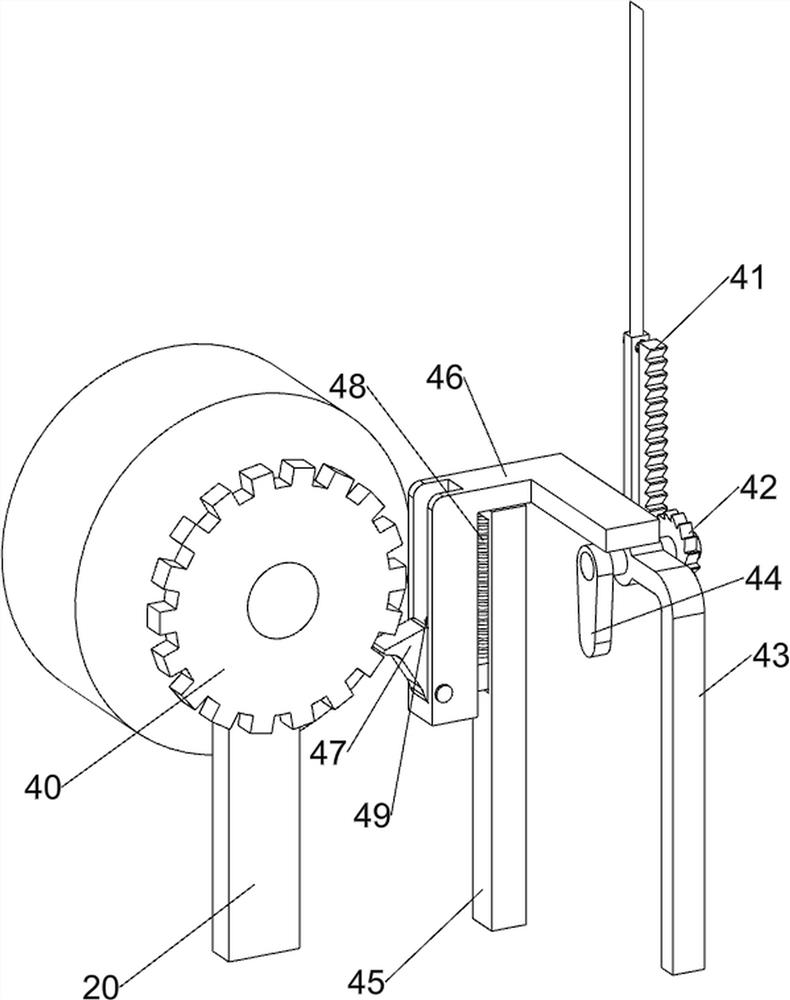

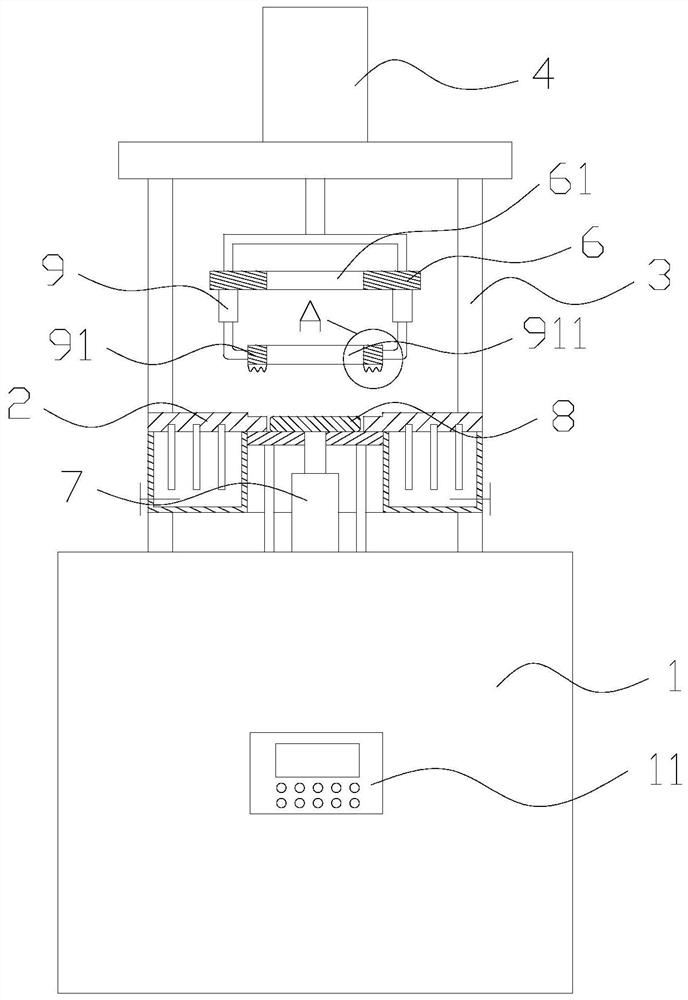

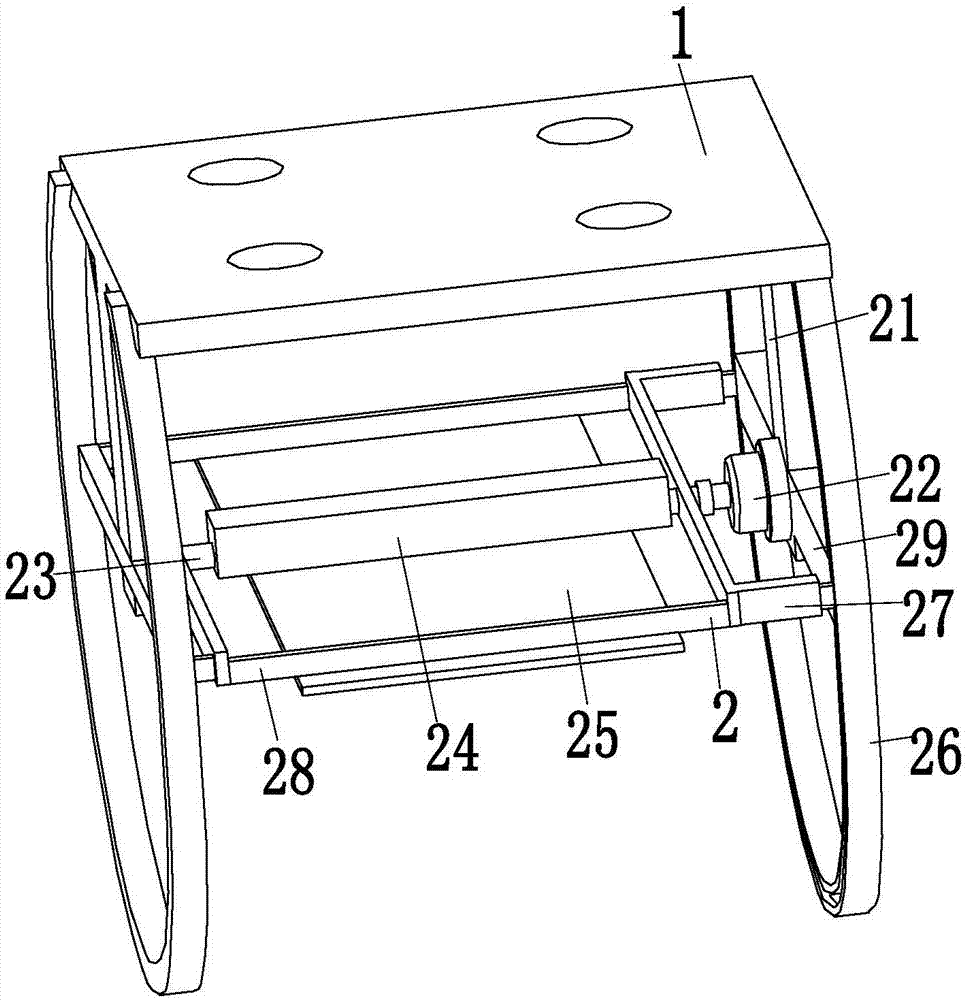

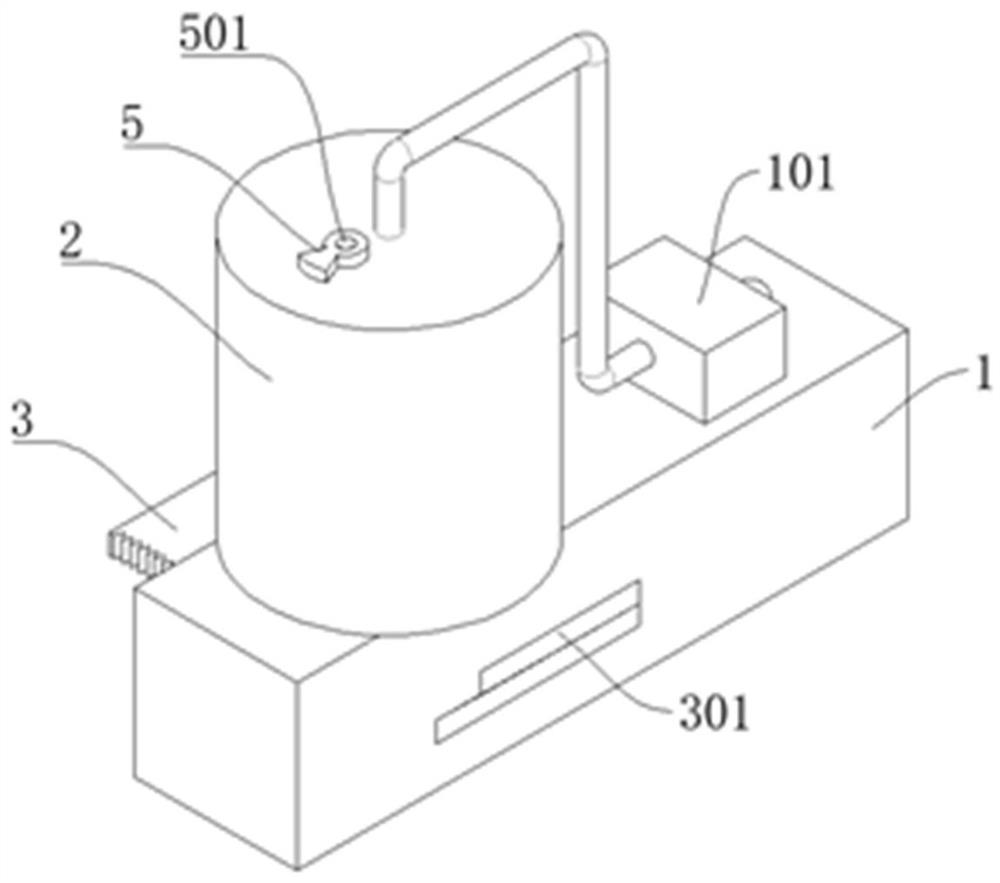

Automatic blanking wafer expander for LED lamps

ActiveCN109860078AEasy to cutAutomatically removedSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringLED lamp

The invention discloses an automatic blanking wafer expander for LED lamps. The wafer expander includes a pedestal, a placing platform used for placing a raw material film, a wafer expanding member which can move up and down, an annular cutting member used for cutting the raw material film, filming pressing members arranged under the annular cutting member, a first driving member used for drivingthe annular cutting member to move up and down, a second driving member used for driving the wafer expanding member to move up and down, and a heating assembly used for heating the raw material film;the annular cutting member is provided with an inclined cutting plane; and the bottom of the cutting plane is provided with a cutter. Through the arrangement of the inclined cutting plane, the cutterarranged at the bottom of the cutting plane can better cuts a waste material film, so that the purpose of automatically removing the waste material film can be realized, working procedures can be decreased, the workloads of workers can be reduced, and production efficiency can be enhanced.

Owner:佛山市恩度照明电器有限公司

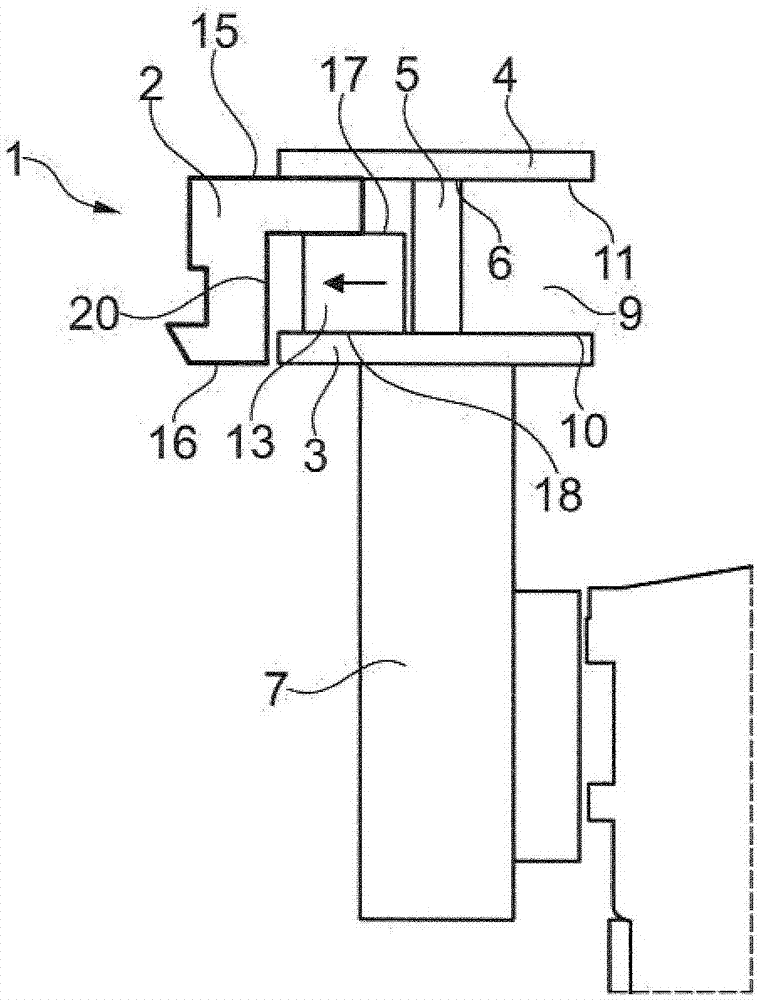

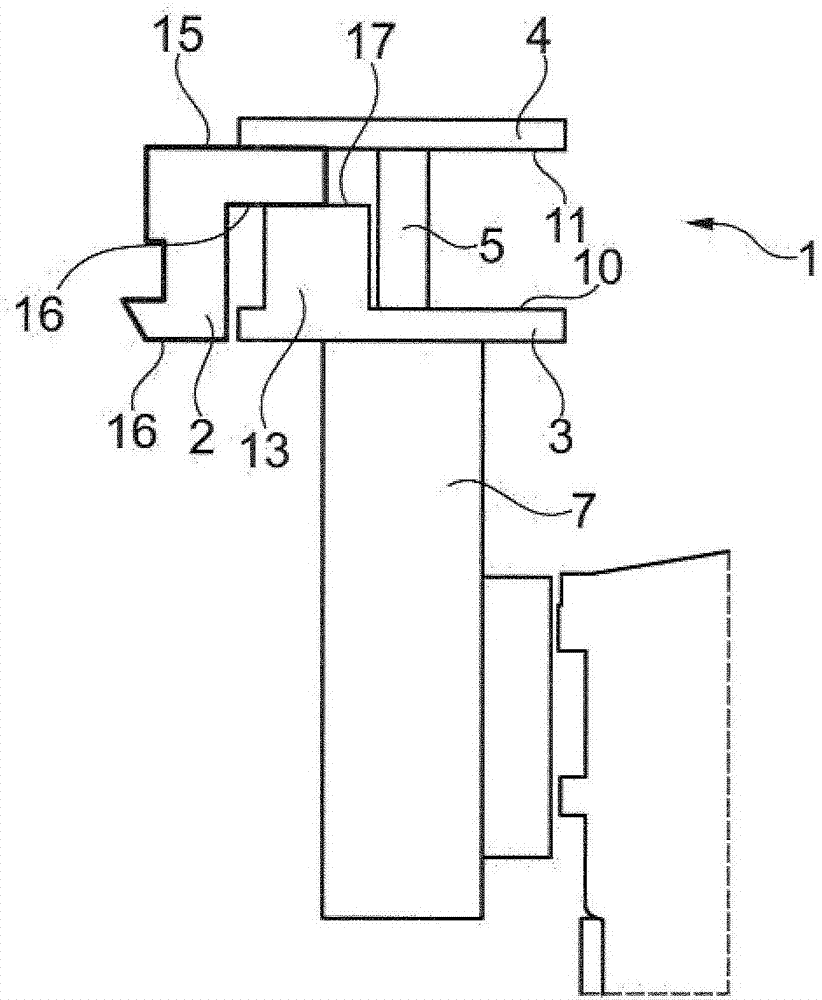

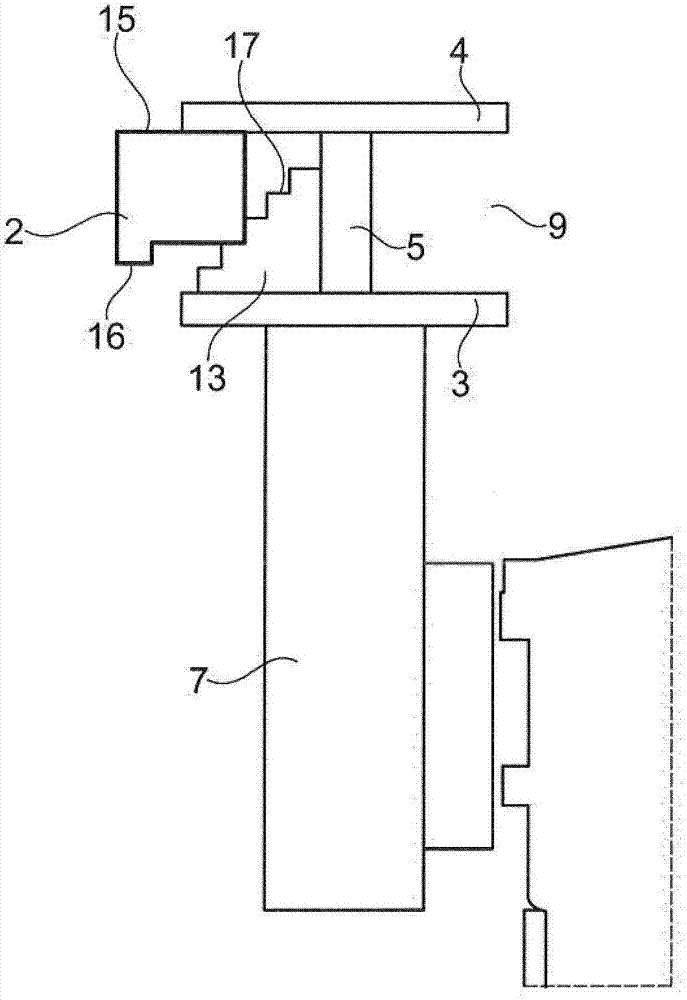

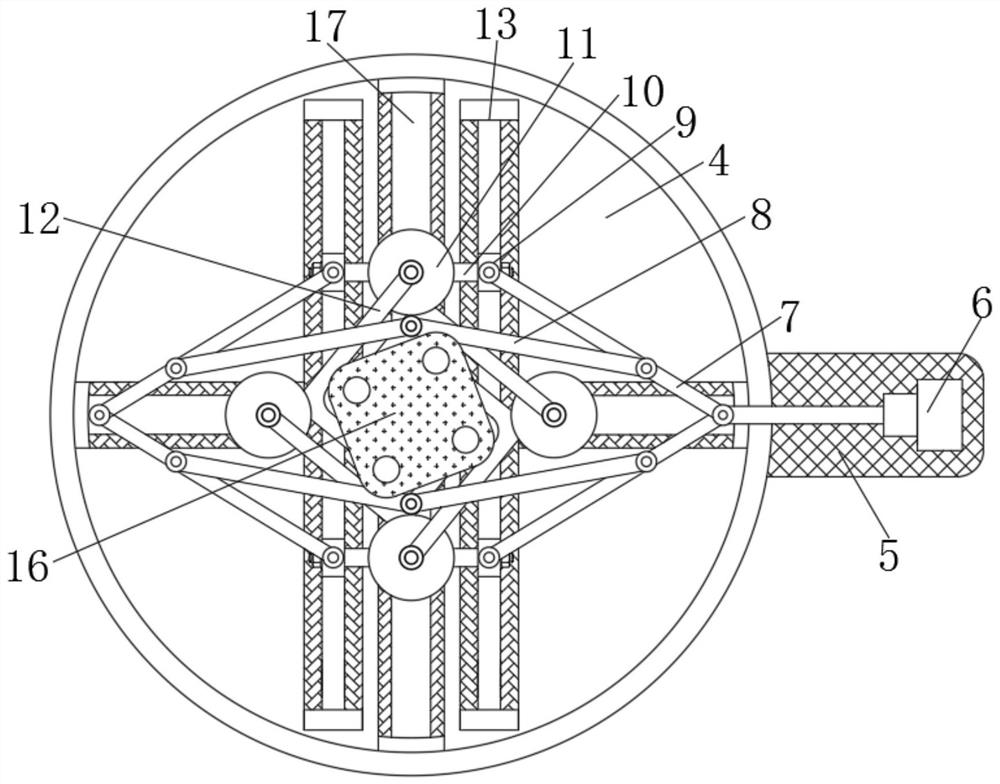

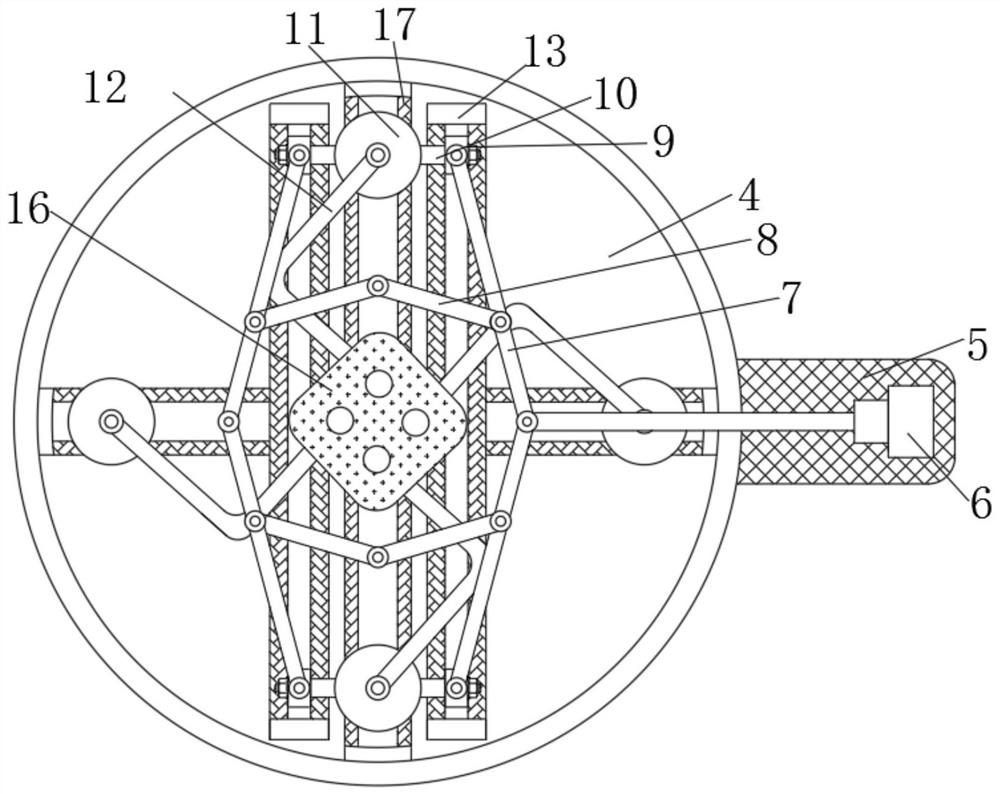

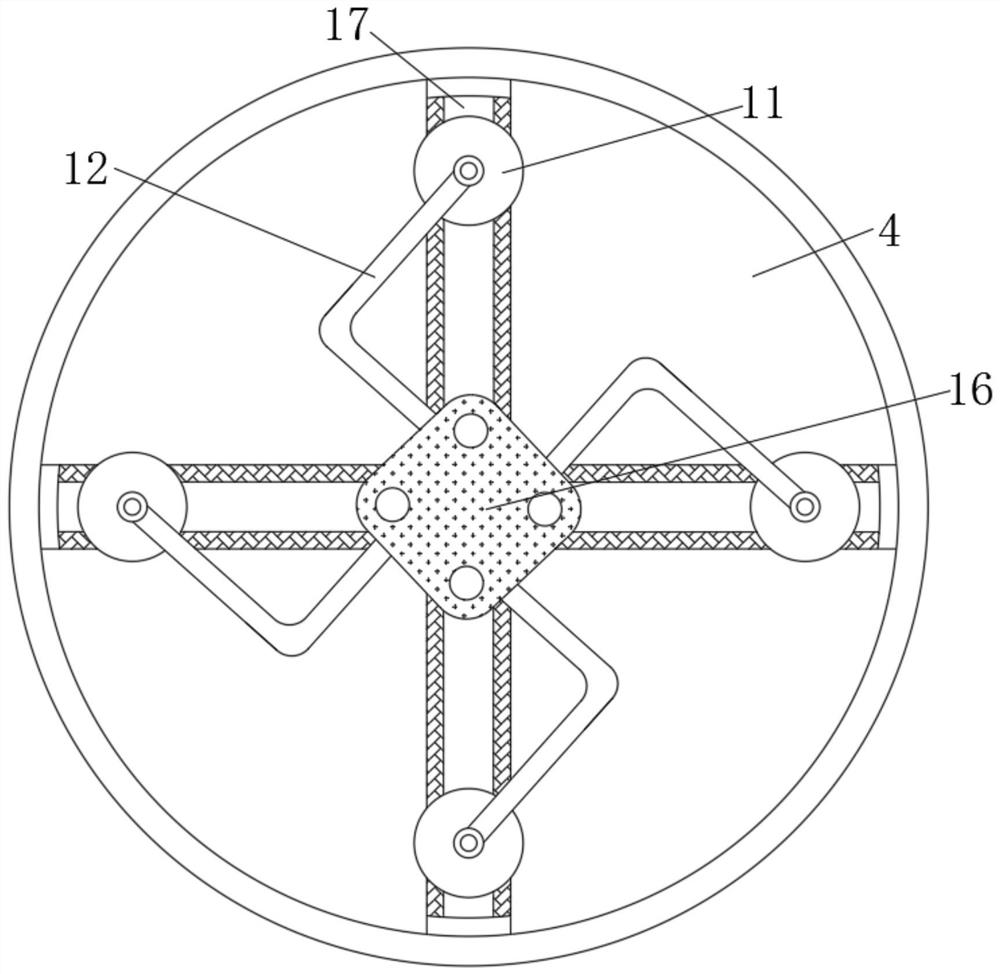

Clamping device

PendingCN107000143AClamp firmlySimple changeover clampingProfiling/shaping machinesPositioning apparatusEngineeringLower face

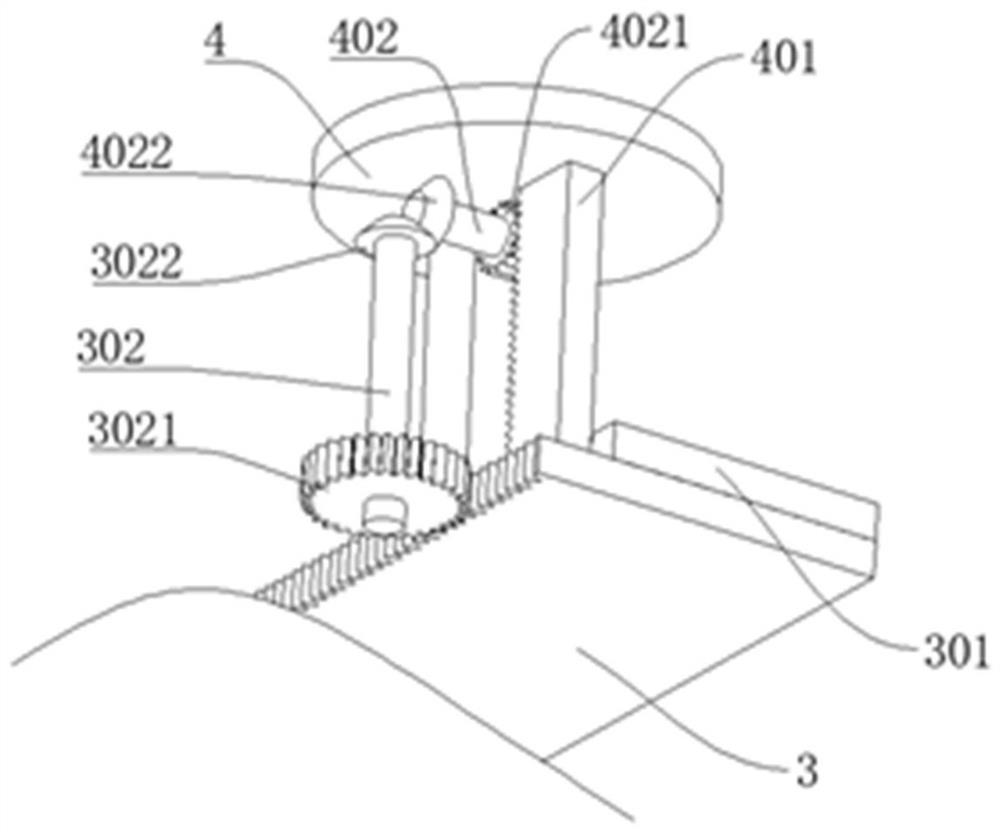

The invention relates to a clamping device (1) for a workpiece (2), comprising a lower clamping element (3) and an upper clamping element (4) which form a workpiece holder (9). The height of the upper clamping element (4) can be adjusted relative to the lower clamping element (3), and the workpiece (2) has at least one outer surface (18) arranged on the lower face and can be inserted into the clamping device (1). The clamping device also comprises a clamping support element (13) which can be provided in the clamping device (1), said clamping support element (13) having at least one outer surface (17) arranged on the upper face. The workpiece (2) and the clamping support element (13) can be clamped together in the clamping device (1), wherein the at least one workpiece (2) outer surface (16) arranged on the lower face and the at least one clamping support element (13) outer surface (17) arranged on the upper face lie flat one on top of the other when the workpiece (2) and the clamping support element (13) are clamped in the clamping device (1).

Owner:OMAX LTD

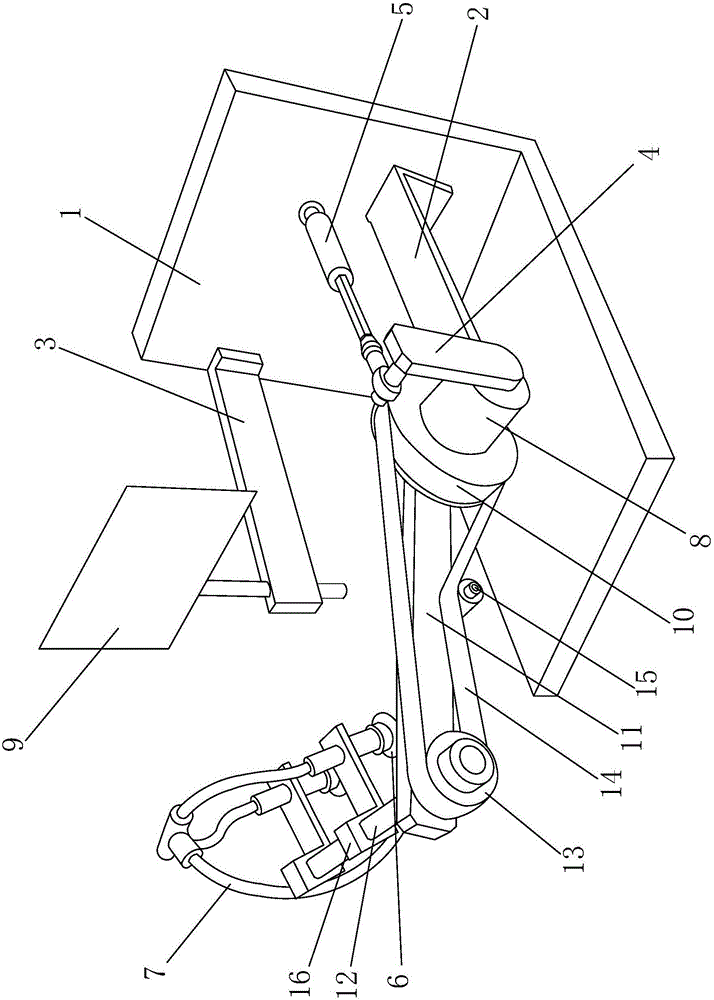

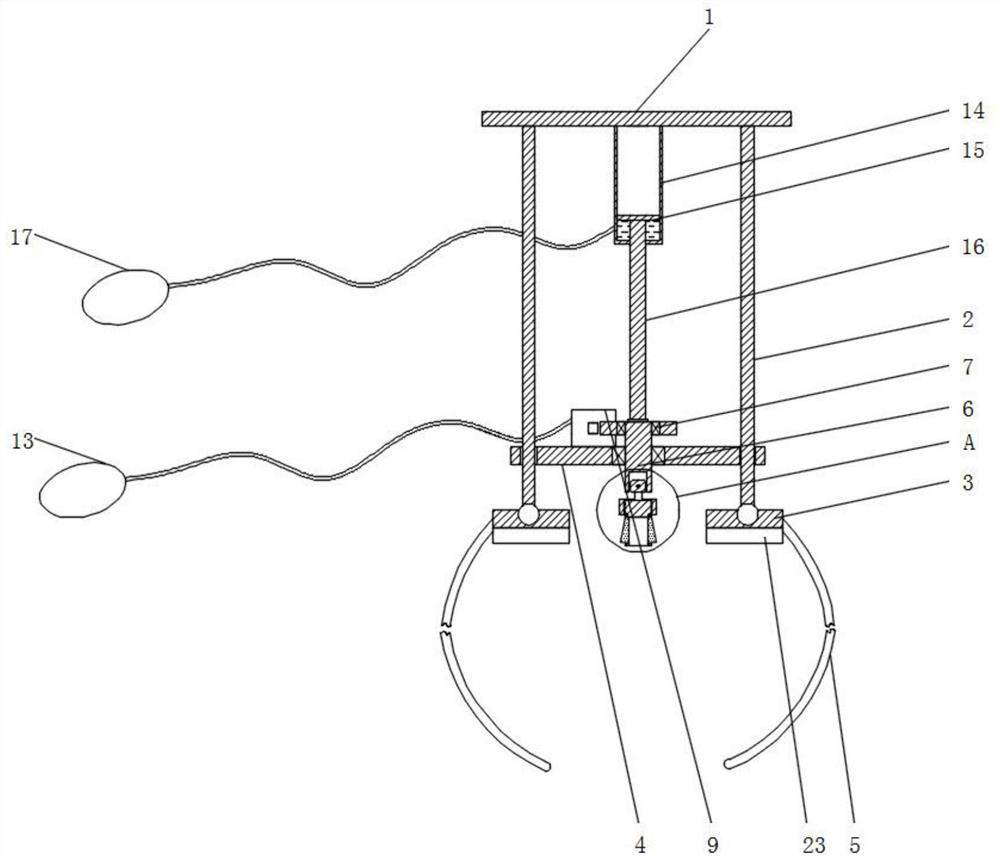

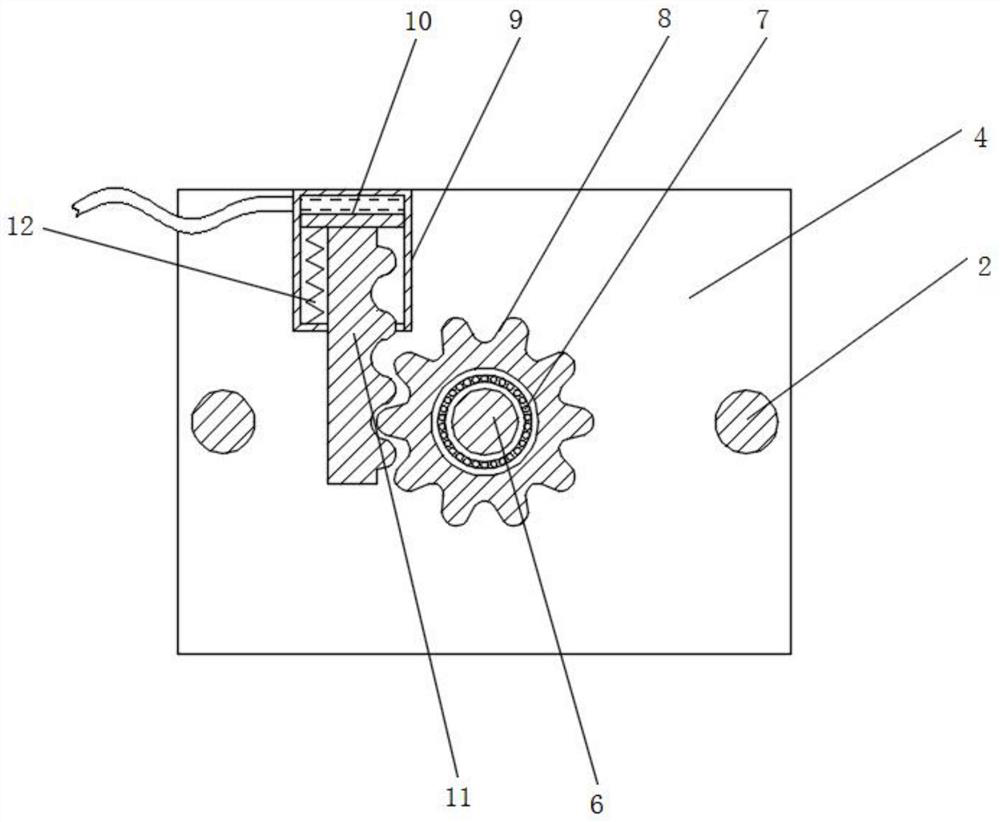

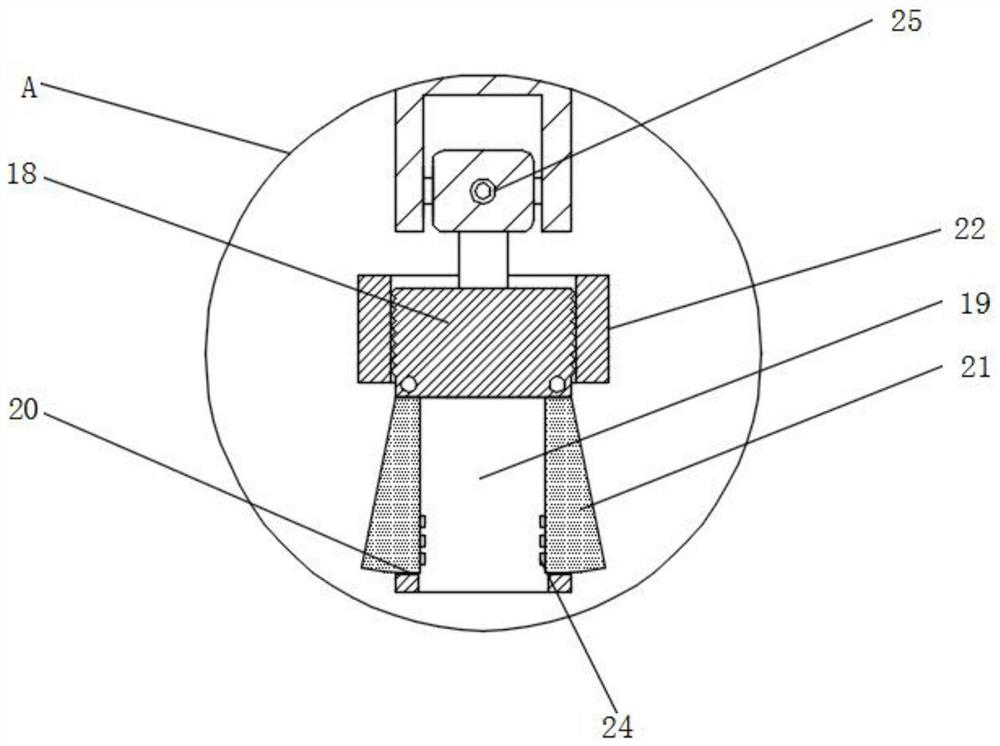

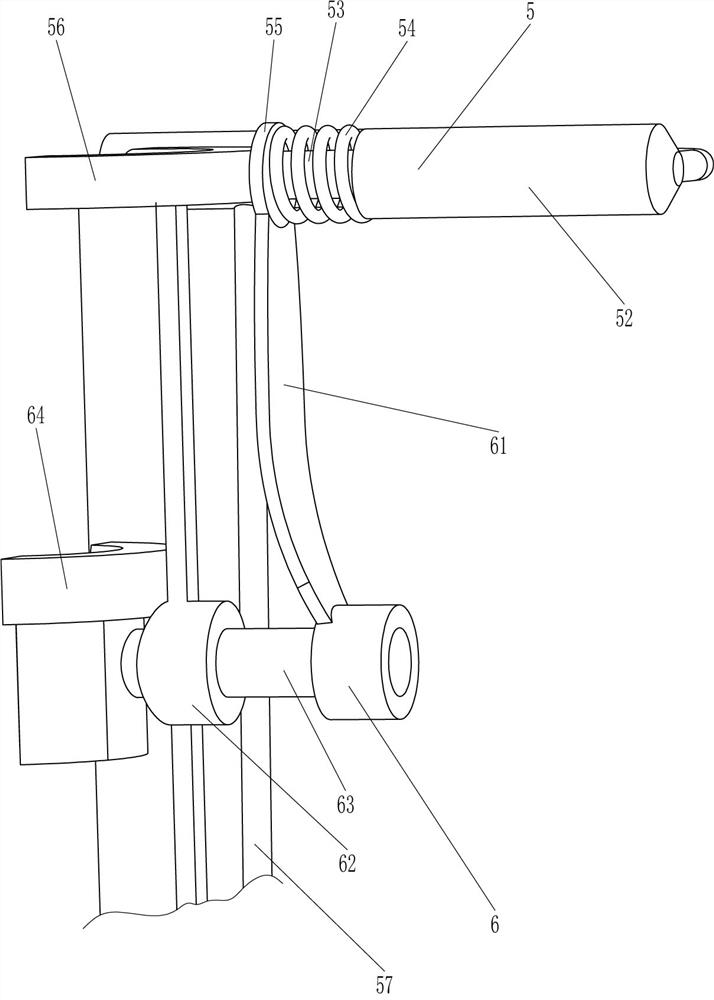

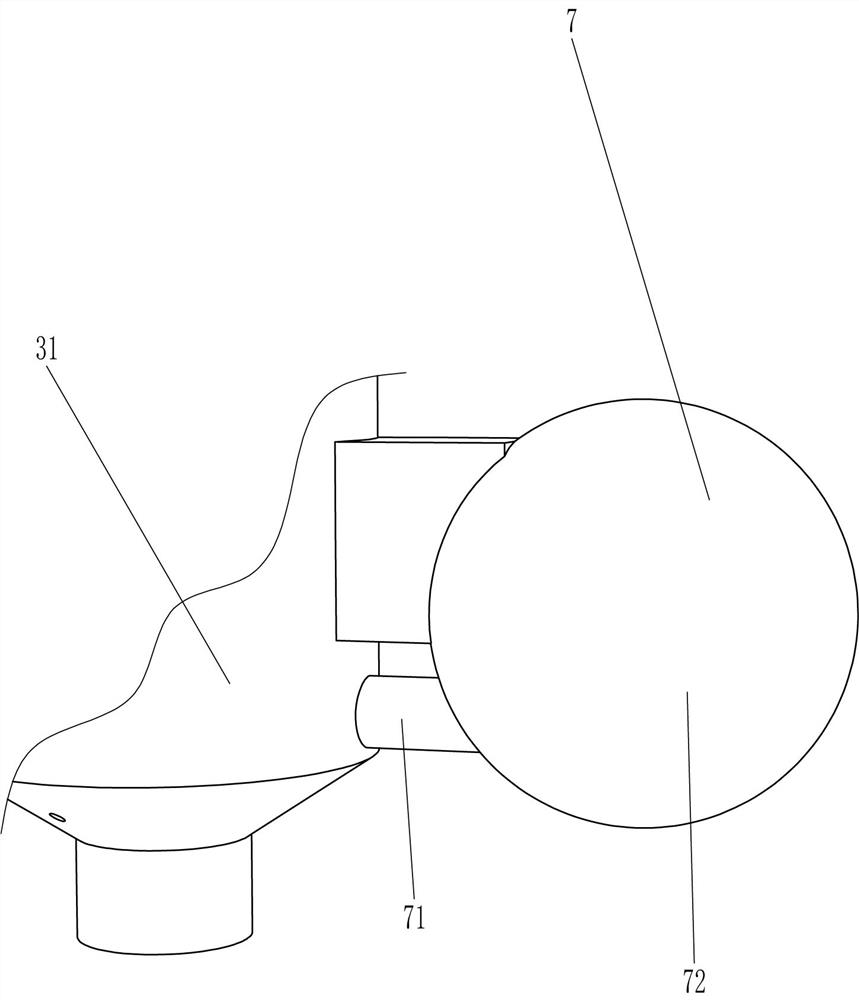

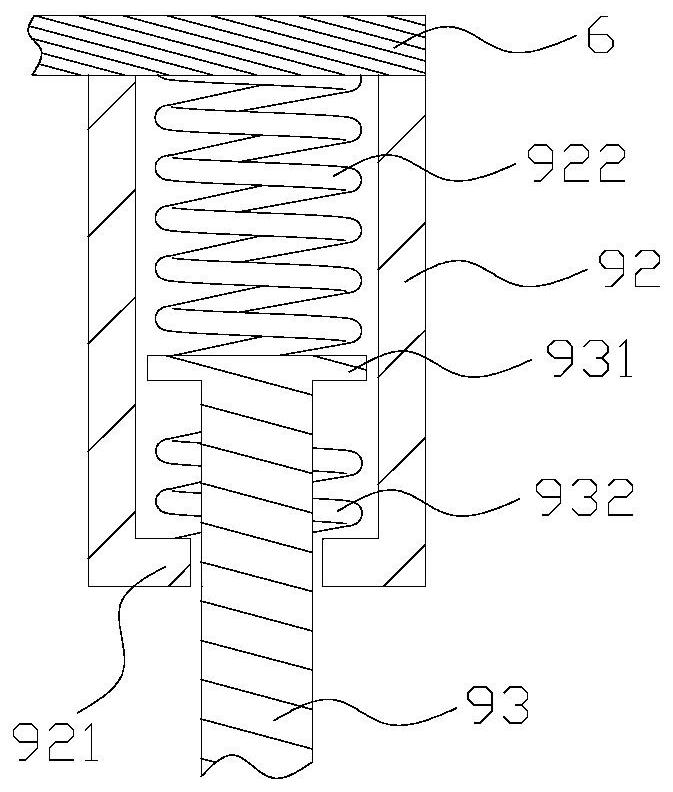

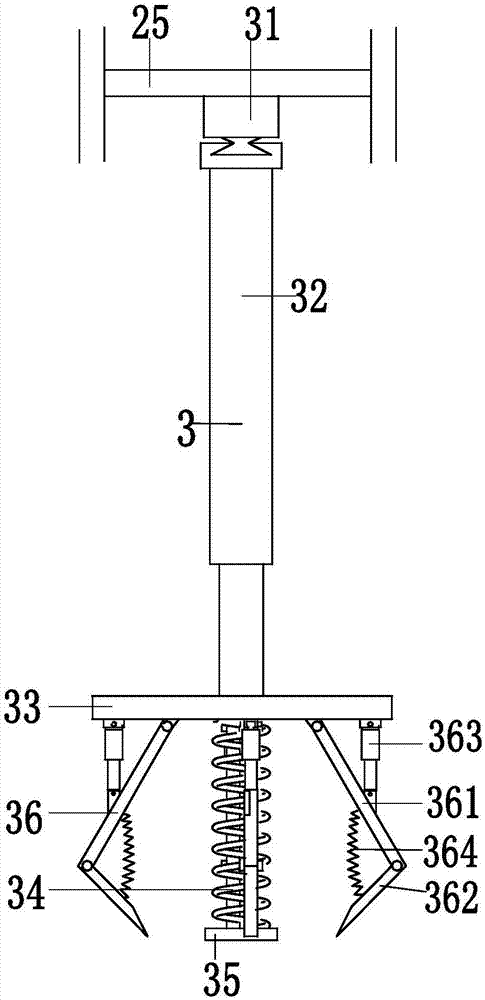

Nail taking device for orthopedics

ActiveCN112494132AAvoid damageReduce tensionOsteosynthesis devicesLow bone densityOrthopedic department

The invention discloses a nail taking device for orthopedics. The nail taking device comprises a positioning unit and a nail taking unit, wherein the positioning unit comprises a top plate, sliding rods vertically arranged at the two ends of the bottom of the top plate, abutting blocks arranged at the bottoms of the sliding rods in a hinged mode, a moving plate arranged between the two sliding rods in a sliding mode and fixing belts arranged on the opposite sides of the two abutting blocks. For a patient with relatively low bone density, a doctor can repeatedly press a pressing bag I with onehand to enable a rotating rod to rotate constantly, and can press a pressing bag II with the other hand to enable hydraulic oil in the pressing bag II to enter a piston cylinder II through a hose, a piston II moves upwards in a piston cylinder I, and a connecting rod is driven to move upwards, so that the connecting rod generates certain tension on the rotating rod to be matched with the rotatingrod to take out a steel nail; and for a patient with relatively high bone density, the doctor only needs to repeatedly press the pressing bag I, a thread is formed on the bone, and therefore, the steel nail is enabled to be automatically moved out.

Owner:THE FIRST AFFILIATED HOSPITAL OF WANNAN MEDICAL COLLEGE YIJISHAN HOSPITAL OF WANNAN MEDICAL COLLEGE

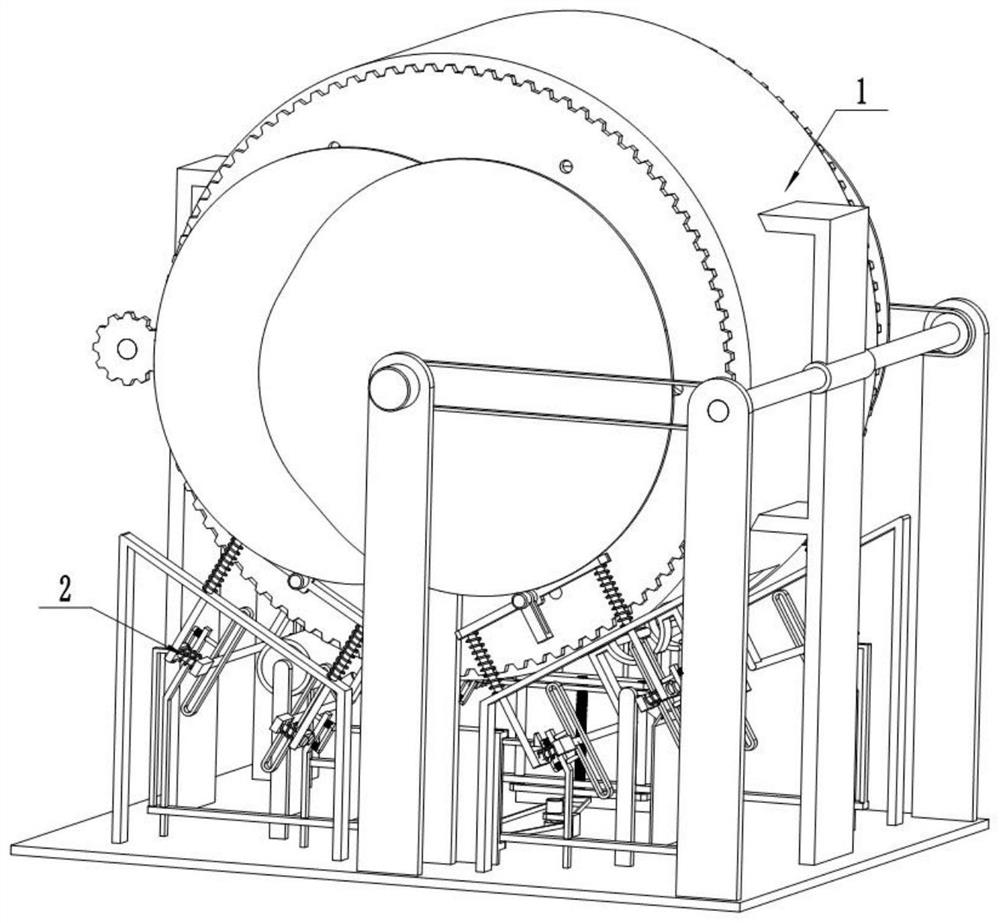

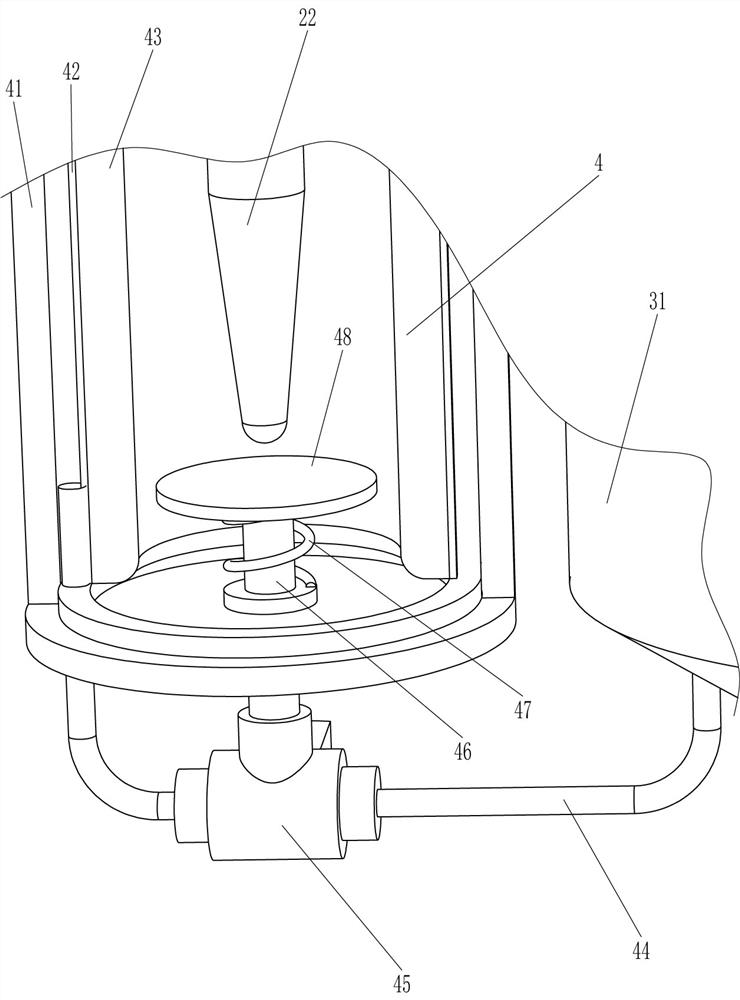

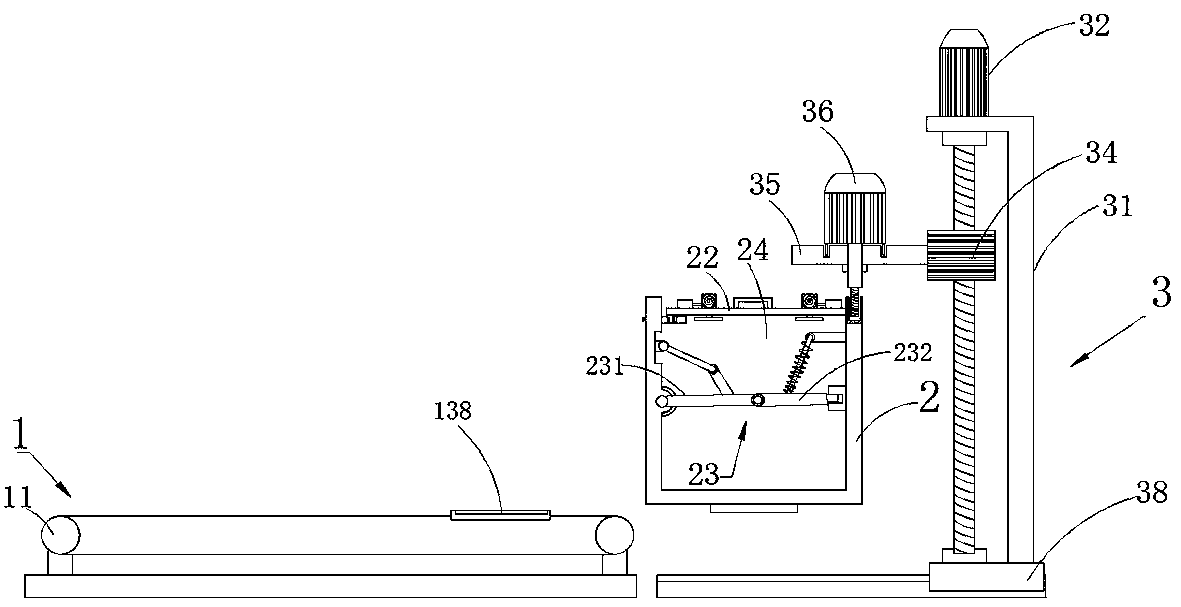

Annular furnace for processing oil well pipe blank

ActiveCN114875228AHeating evenlyAutomatically removedIncreasing energy efficiencyFurnace typesElectric machineStructural engineering

The invention discloses an annular furnace for oil well pipe blank machining, and relates to the technical field of oil pipe blank machining device.The annular furnace comprises a heating assembly for heating a plurality of pipe blanks at the same time, a plurality of clamping discs capable of clamping the pipe blanks are arranged in the heating assembly, a rotating fire spraying pipe is arranged in the heating assembly, and the fire spraying pipe heats the pipe blanks; and the lower end of the heating assembly is provided with a replacing assembly for automatically replacing the pipe blank, the replacing assembly drives a clamping ring to clamp the pipe blank through an arranged convex face disc, and the pipe blank is taken out of the heating assembly or placed into the heating assembly under the driving of a replacing motor. And the function of automatically replacing the pipe blank is achieved.

Owner:JIANGSU VALIN XIGANG SPECIAL STEEL

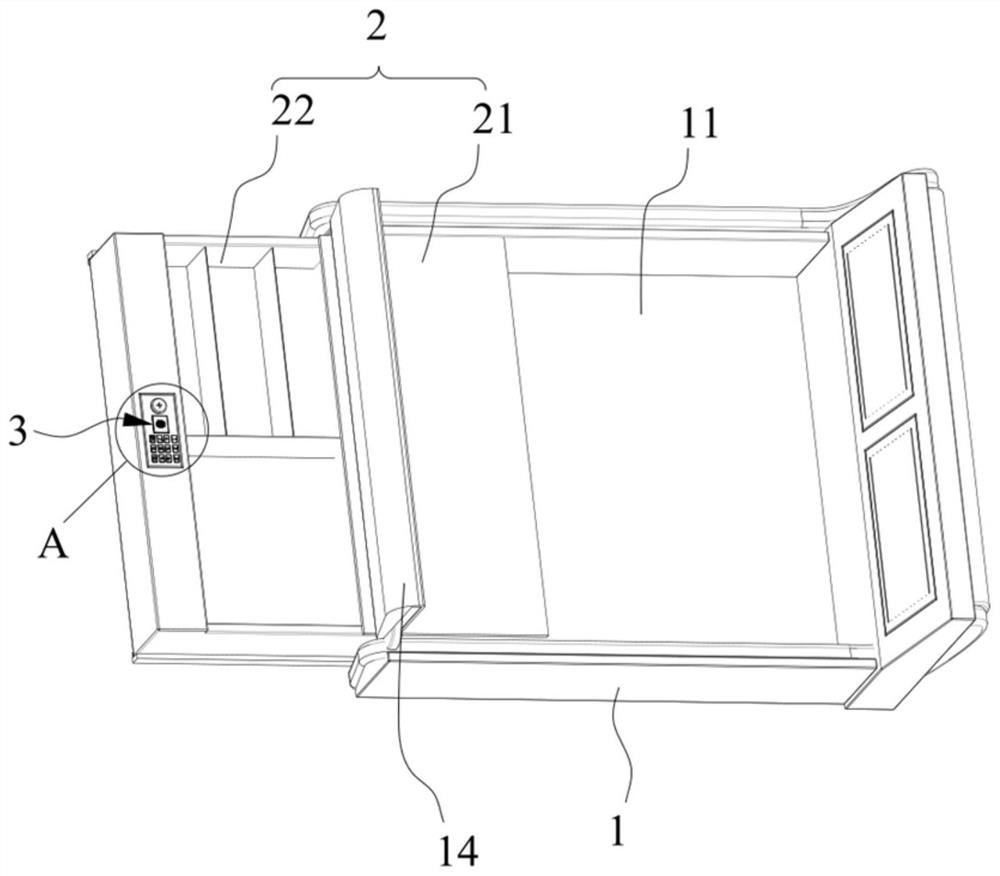

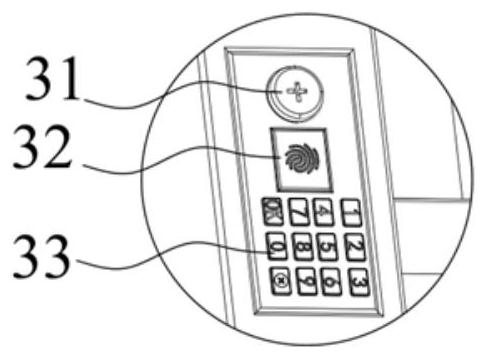

Bed with safety box function and safety box using method thereof

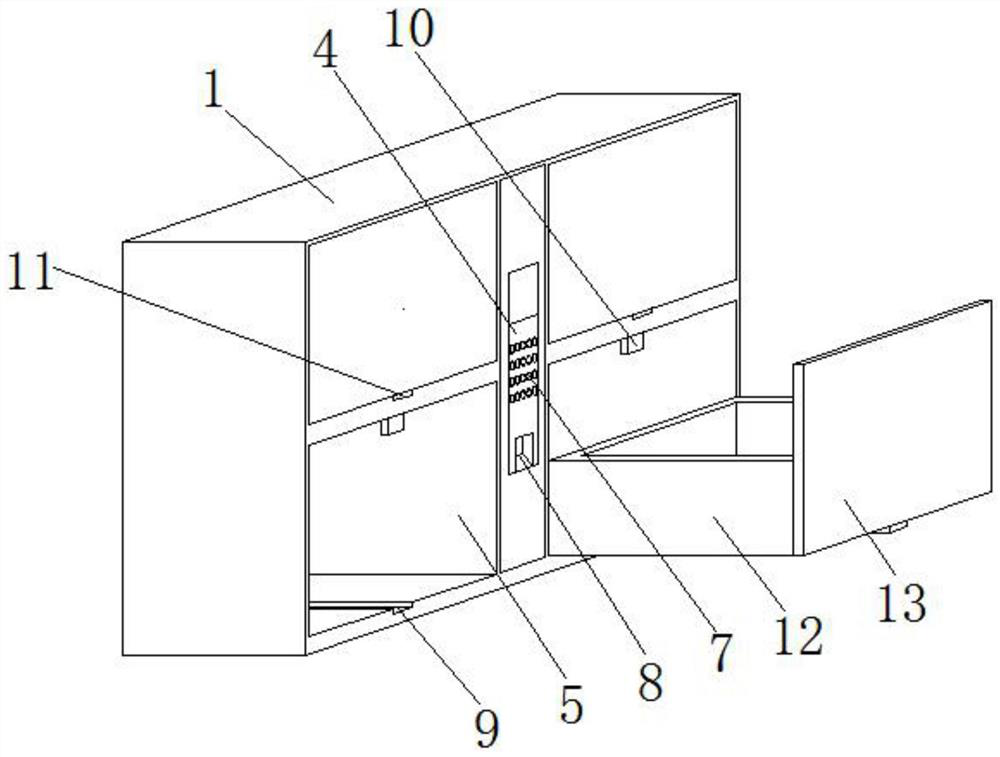

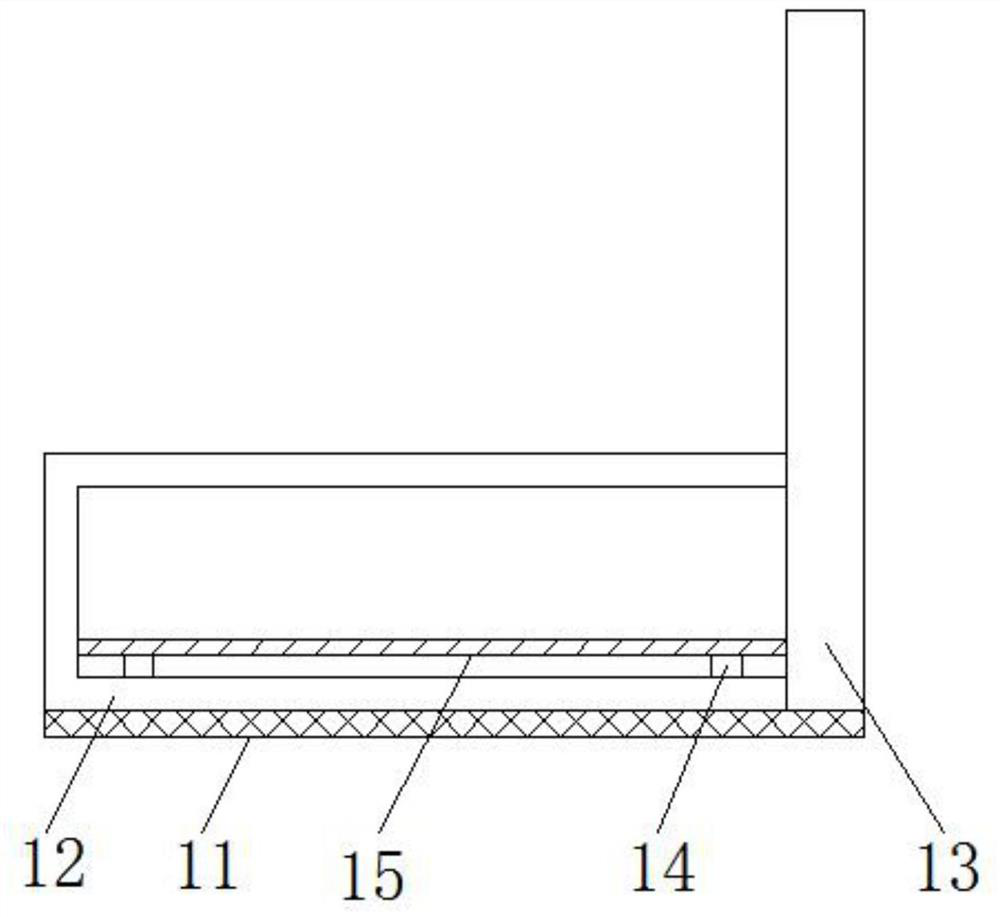

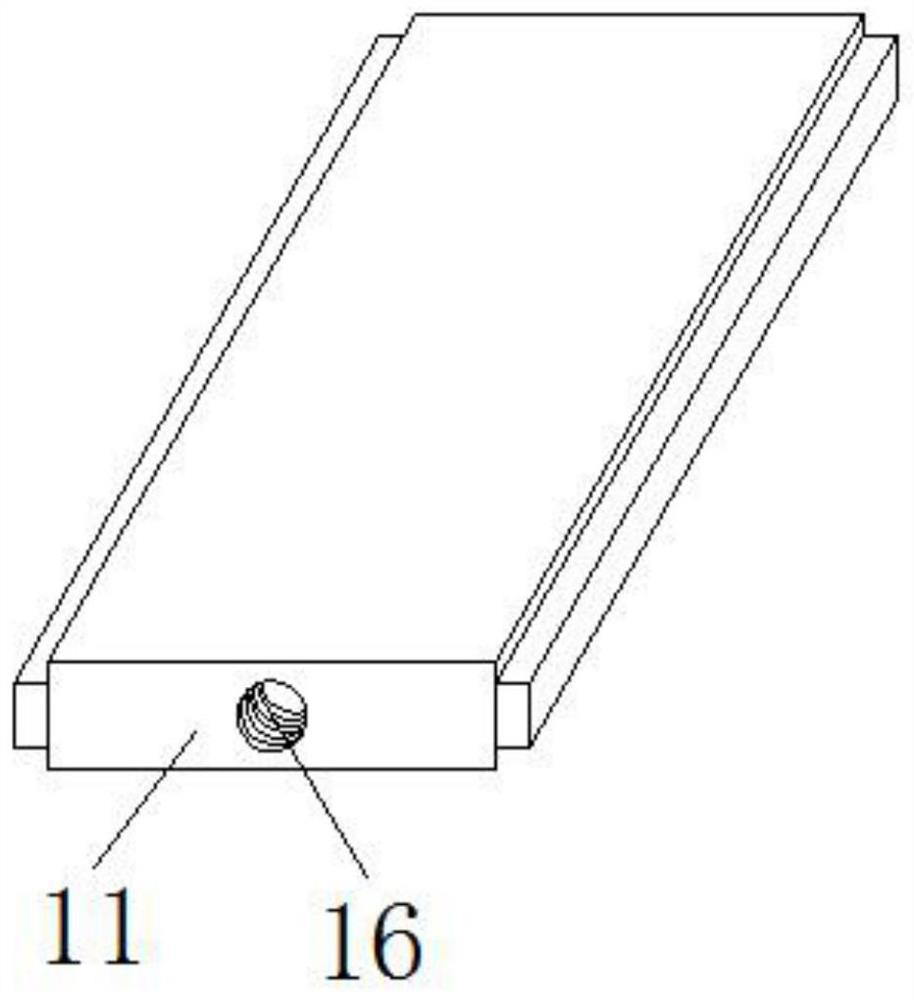

PendingCN112450644AAutomatically removedHidden locationBedstandsElectric permutation locksControl engineeringControl theory

The invention discloses a bed with a safety box function, and belongs to the technical field of safety boxes. The bed comprises a bed frame, a safety box mechanism, a voiceprint recognition module anda control module. The safety box mechanism comprises a safety box which is arranged at the bottom of the bed frame in a sliding mode and can automatically stretch out of the bed frame and retract into the bed frame. The safety box comprises an intelligent lock, and the intelligent lock can be unlocked in any mode of fingerprints, passwords or keys to open the safety box; the voiceprint recognition module is arranged on the bed frame and can control the safety box to extend out of the bed frame through voice information; the control module is in communication connection with the safety box mechanism and the voiceprint recognition module, and the control module is used for receiving signals from the voiceprint recognition module and controlling the safety box mechanism to act. The inventionfurther provides a using method of the safety box, and the safety box can be automatically opened through the bed with the safety box function. The bed with the safety box function is hidden in position, good in safety and reasonable in space saving.

Owner:DONGGUAN DERUCCI BEDDING CO LTD

Wound iron scrap filtering-out processor for industrial injury patient for internal medicine department

ActiveCN111904757AEasy to useAutomatically removedCleaning using toolsNursing accommodationScrapBiomedical engineering

The invention relates to a scrap filtering-out processor, and in particular relates to a wound iron scrap filtering-out processor for an industrial injury patient for the internal medicine department.The invention aims to provide the wound iron scrap filtering-out processor for the industrial injury patient for the internal medicine department, which can quickly adsorb iron scraps so as to avoidaggravation of a wound. The technical scheme is as follows: the wound iron scrap filtering-out processor for the industrial injury patient for the internal medicine department comprises a base, fixingplates, a scraping mechanism and a pressurizing mechanism; the fixing plates are evenly arranged on the top of the base; the fixing plate at the side part is connected with the scraping mechanism; the fixing plate in the middle is connected with the pressurizing mechanism; one side of the upper part of the pressurizing mechanism makes extrusion contact with a handle; and the pressurizing mechanism is connected with the scraping mechanism. Due to cooperation of the pressurizing mechanism and the scraping mechanism, iron scraps on a film on the outer wall of a rubidium magnetic rod can be removed by utilization of the principle of air pressure, so that the processor is convenient to use in next time.

Owner:朱宝欣

Labeling machine

PendingCN112874962AAutomatically removedImprove adsorption capacityLabelling machinesControl engineeringElectric machinery

The invention relates to a labeling machine. The labeling machine comprises a labeling machine body fixedly connected to a work table, the labeling machine body is provided with a label discharging device, the label discharging device comprises a driving mechanism and a label taking mechanism, the driving mechanism comprises a first motor, the first motor is arranged on the side wall of the labeling machine body, and the first motor is fixedly connected with a transmission mechanism. The transmission mechanism is fixedly connected with a first rotating rod, the first rotating rod is fixedly connected with a label winding drum, the label taking mechanism comprises a label discharge plate, the label discharge plate and the first rotating rod are fixedly connected to the side wall of the labeling machine body, a distance sensor is arranged on the label inlet side of the label discharge plate and electrically connected with a controller, and the controller is electrically connected with the first motor. A bonding device is fixedly connected to the work table. The distance sensor detects the transmission distance between two labels and transmits a detection signal to the controller, and the controller responds to the detection signal and controls the first motor to be started or stopped. The labeling efficiency and quality can be improved.

Owner:LINGLIAN AUTO PARTS MFG SHANGHAI CO LTD

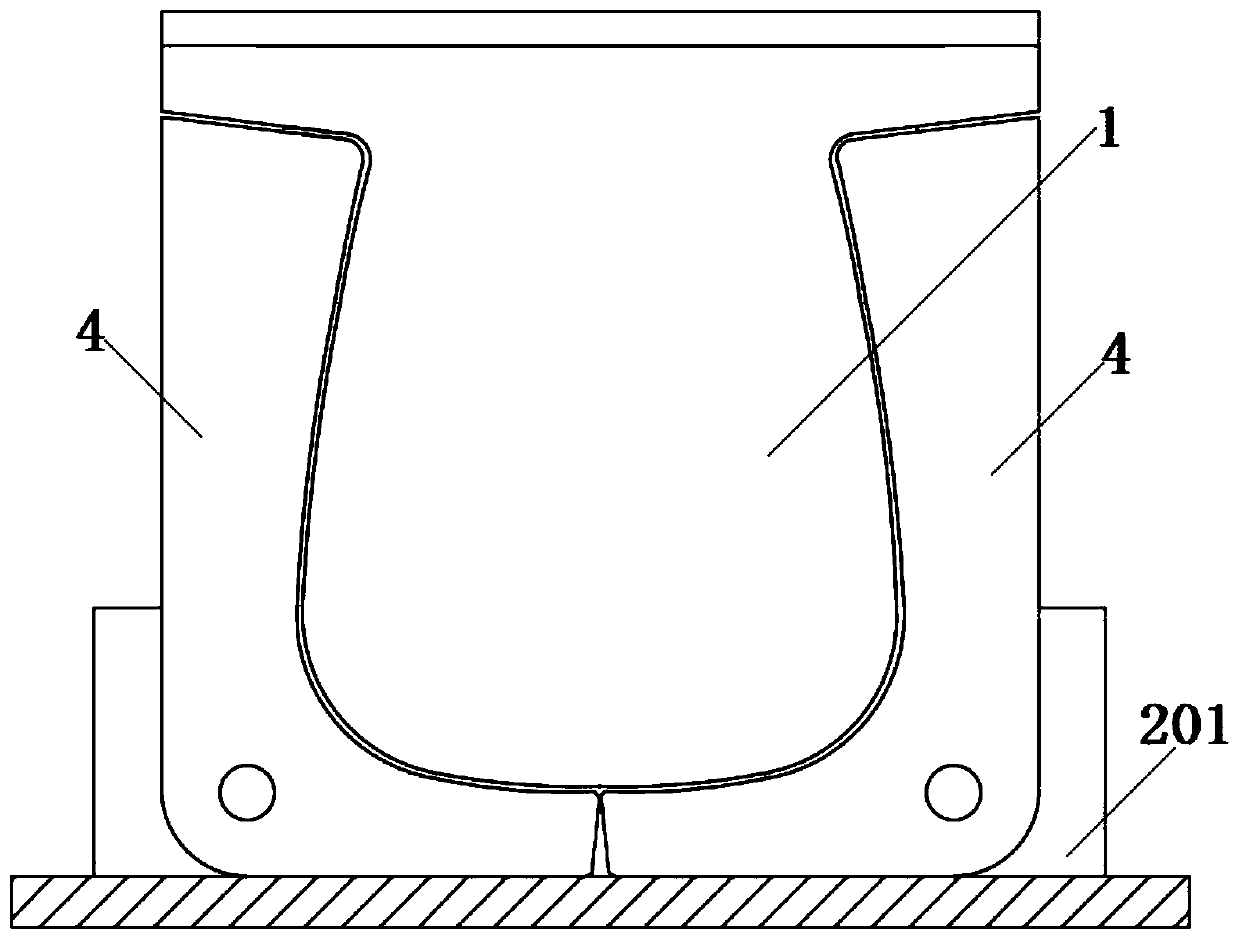

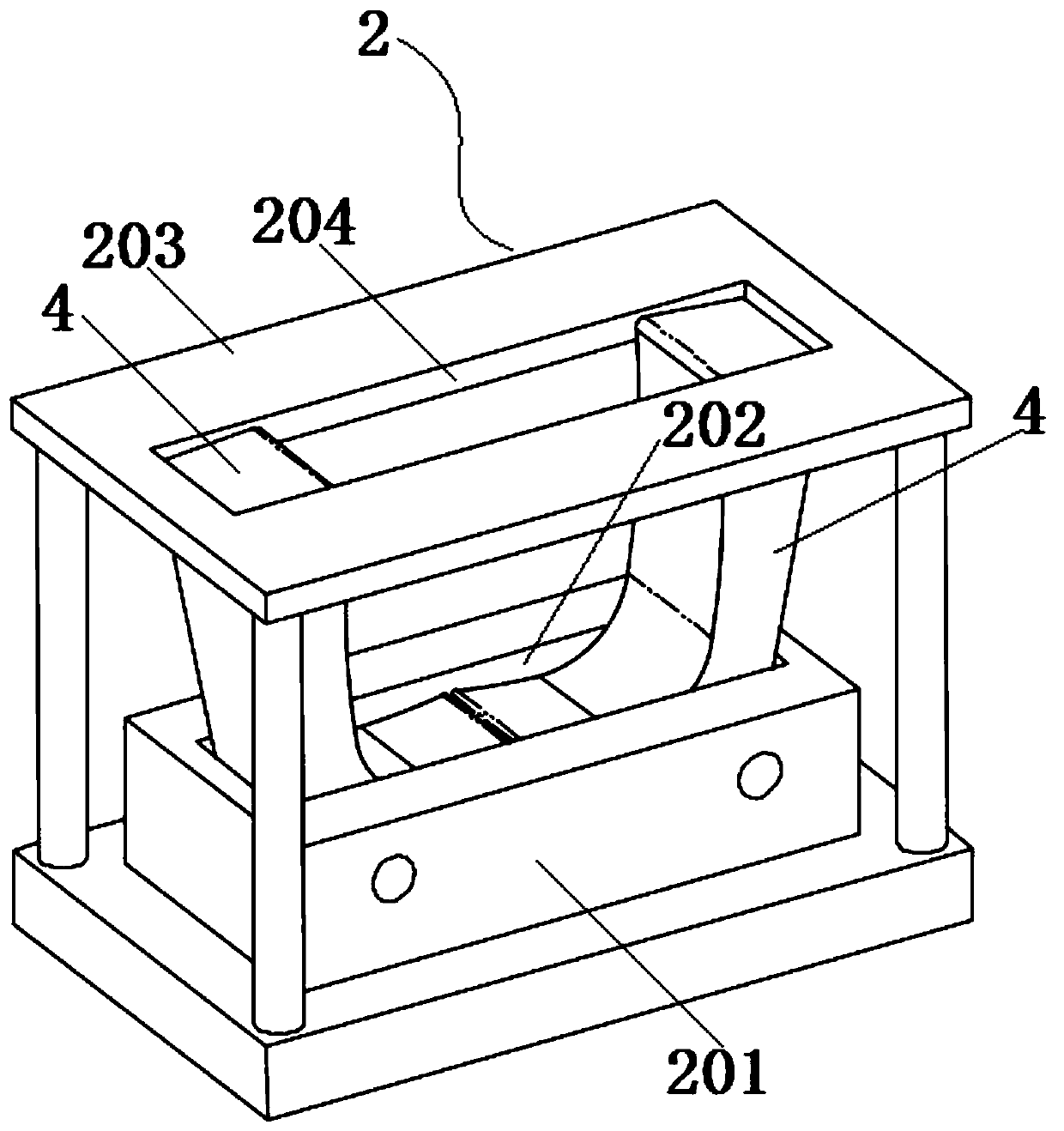

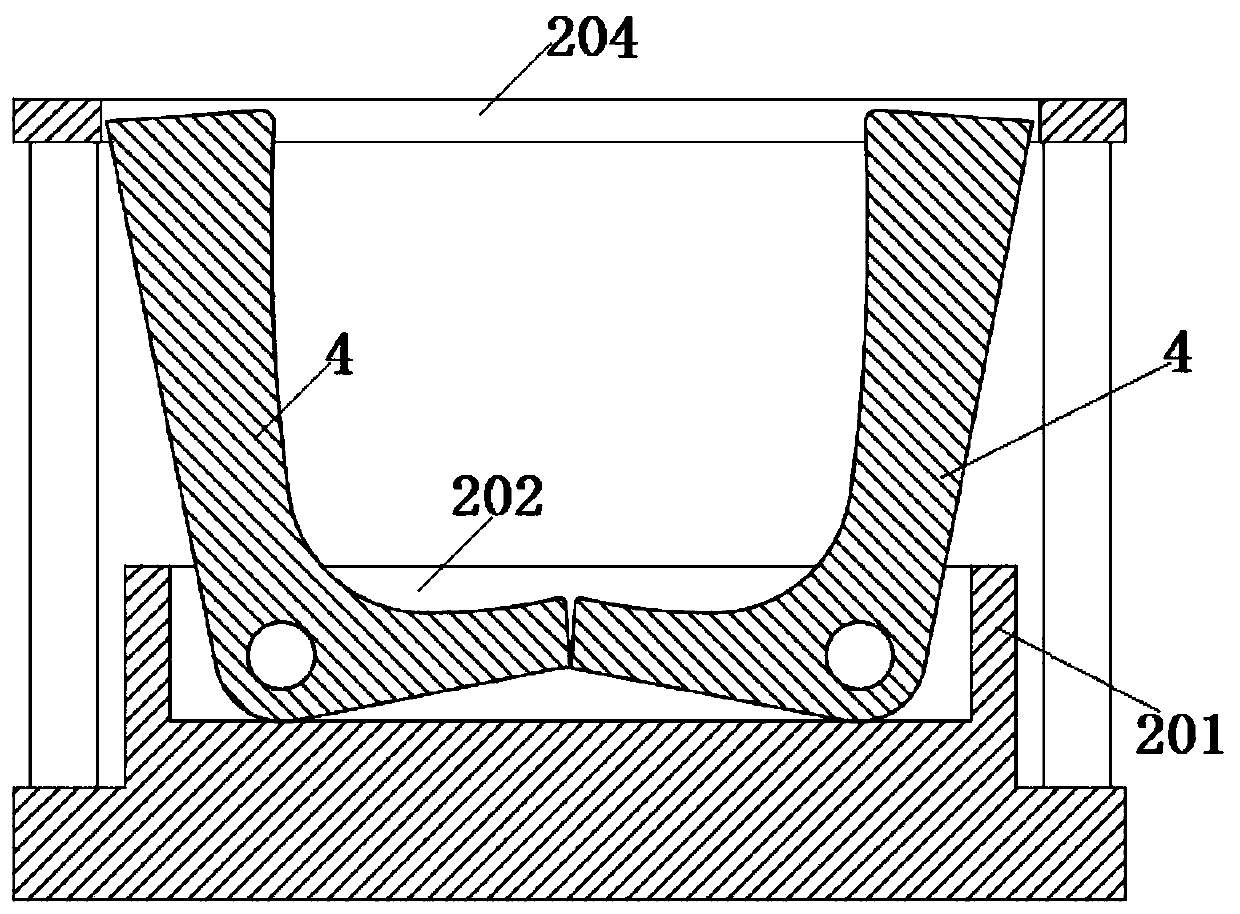

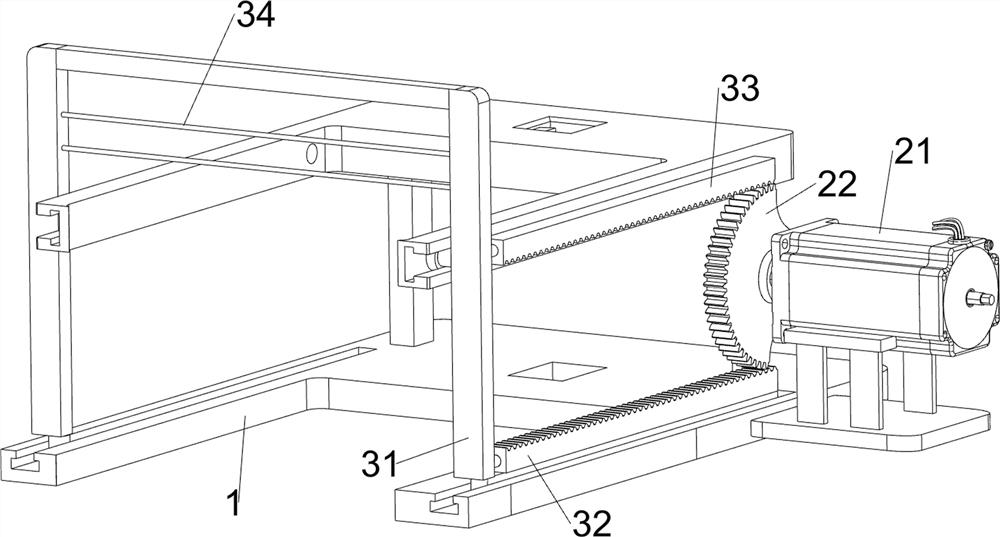

Forming die for large hoop

InactiveCN111390026AAvoid secondary processingIncrease productivityShaping toolsEjection devicesEngineeringStructural engineering

Owner:HEFEI ZHENGTE MACHINERY CO LTD

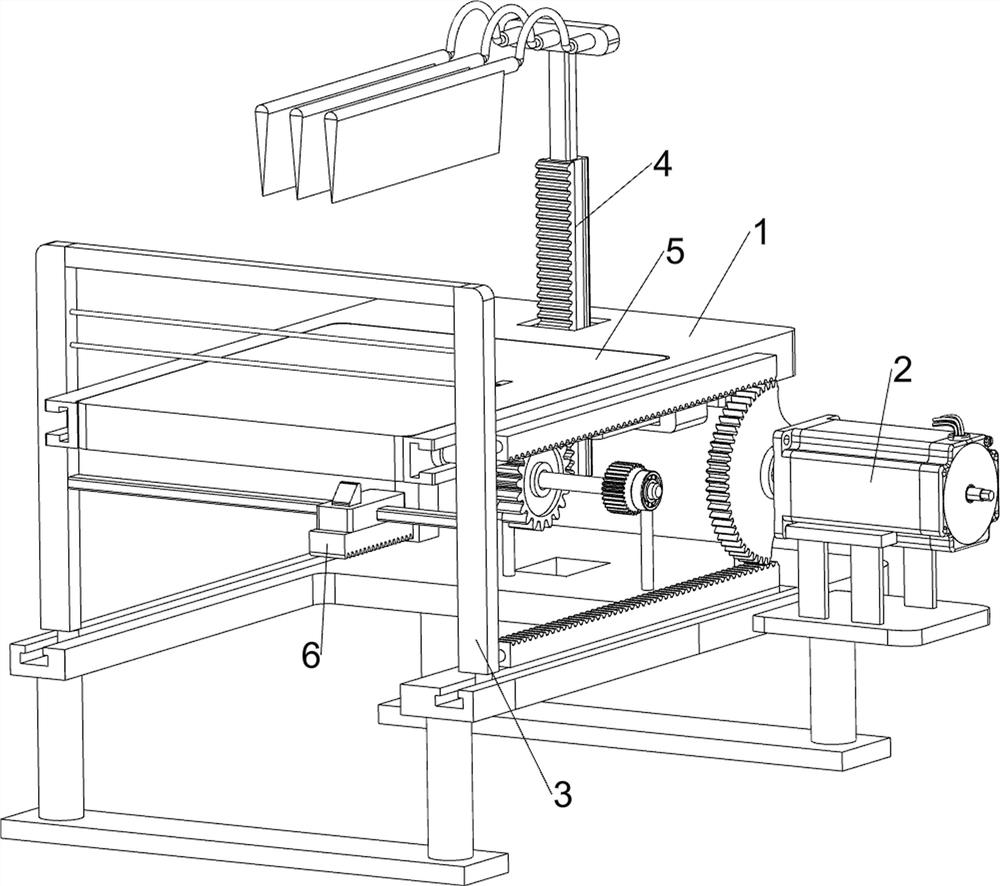

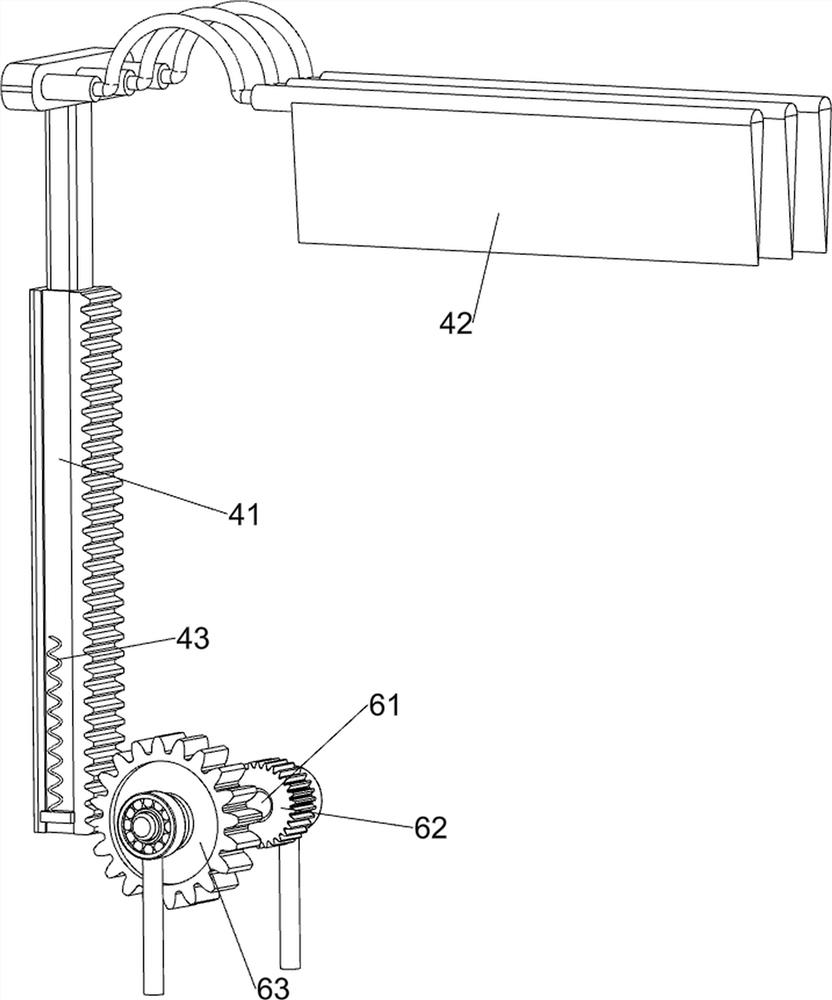

Automatic bean curd slitting device

PendingCN112847618AEase of useEasy to removeMetal working apparatusAgricultural engineeringStructural engineering

The invention relates to a slitting device, in particular to an automatic bean curd slitting device. The automatic bean curd slitting device can be used for safely and uniformly slitting bean curd. The automatic bean curd slitting device comprises a support, a power assembly, a transverse cutting assembly and a longitudinal cutting assembly, wherein the power assembly is mounted on the support; the transverse cutting assembly is mounted on the support; and the longitudinal cutting assembly is mounted on the support. Through cooperation of the power assembly and the transverse cutting assembly, a steel wire can be driven to automatically move front and back to slit bean curd; the slit bean curd can be quickly taken down through a discharging assembly; and by means of a triggering assembly, bean curd can be automatically cut longitudinally; meanwhile, the slit bean curd can be automatically taken down; and the device is very convenient to use.

Owner:李玉庚

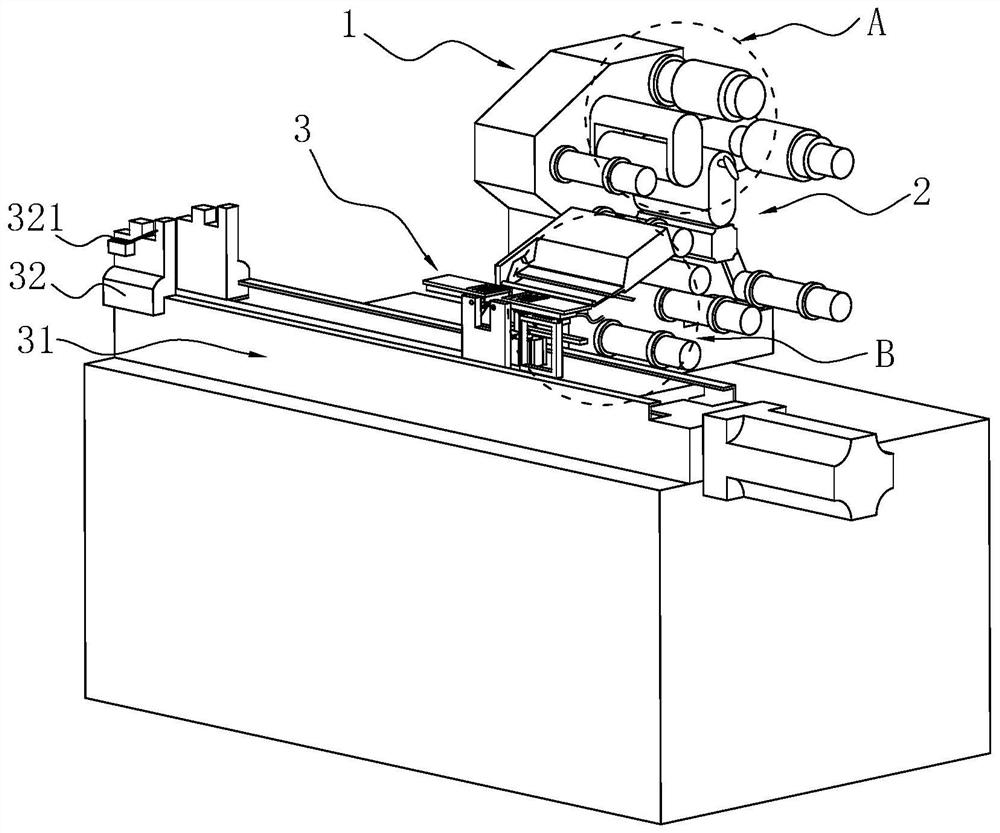

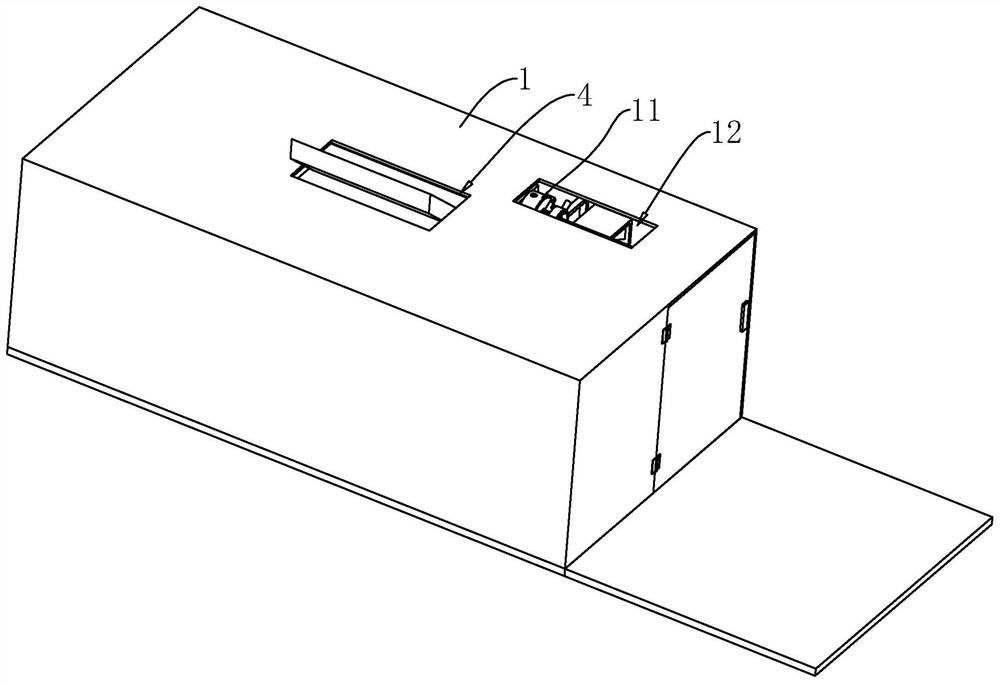

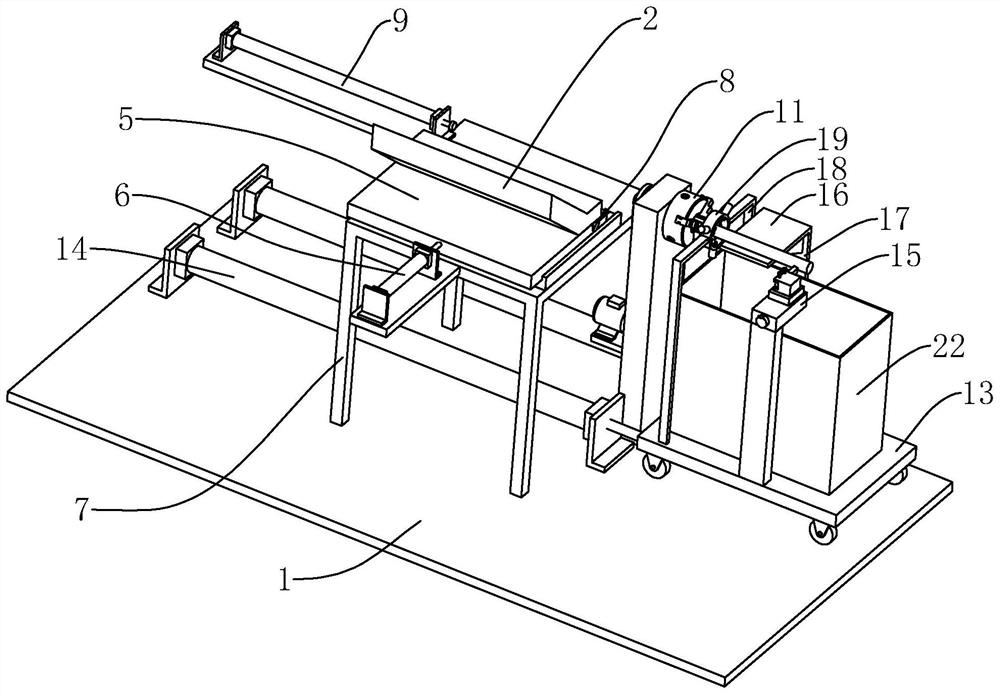

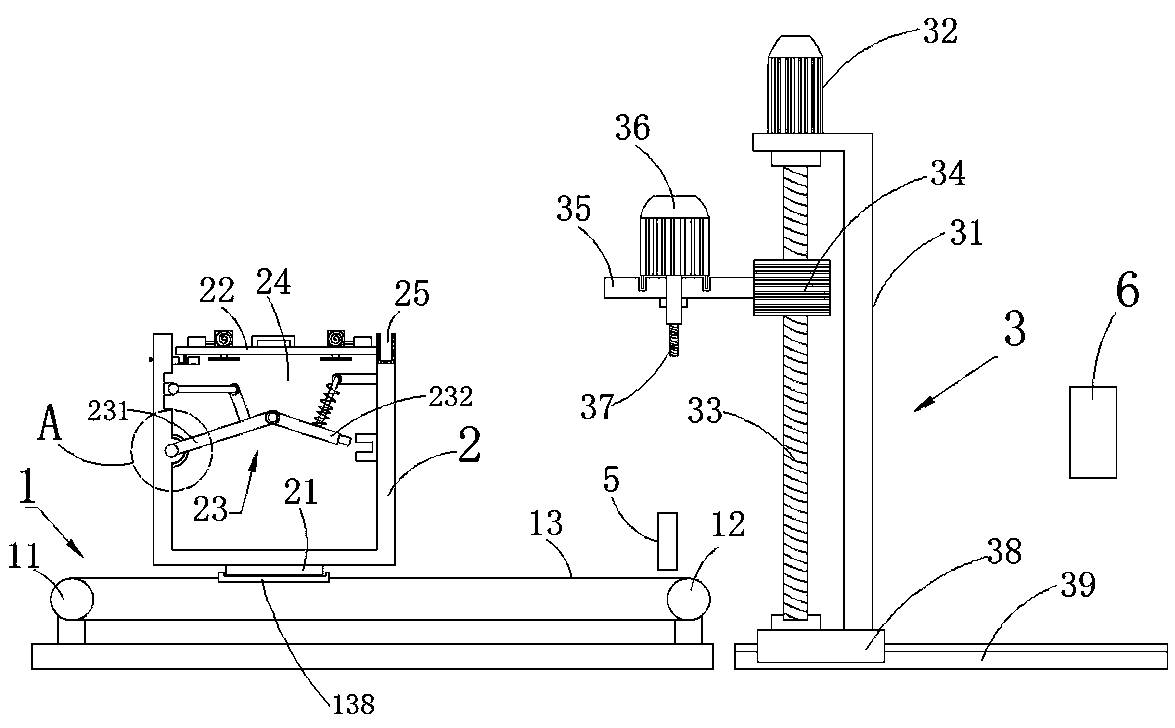

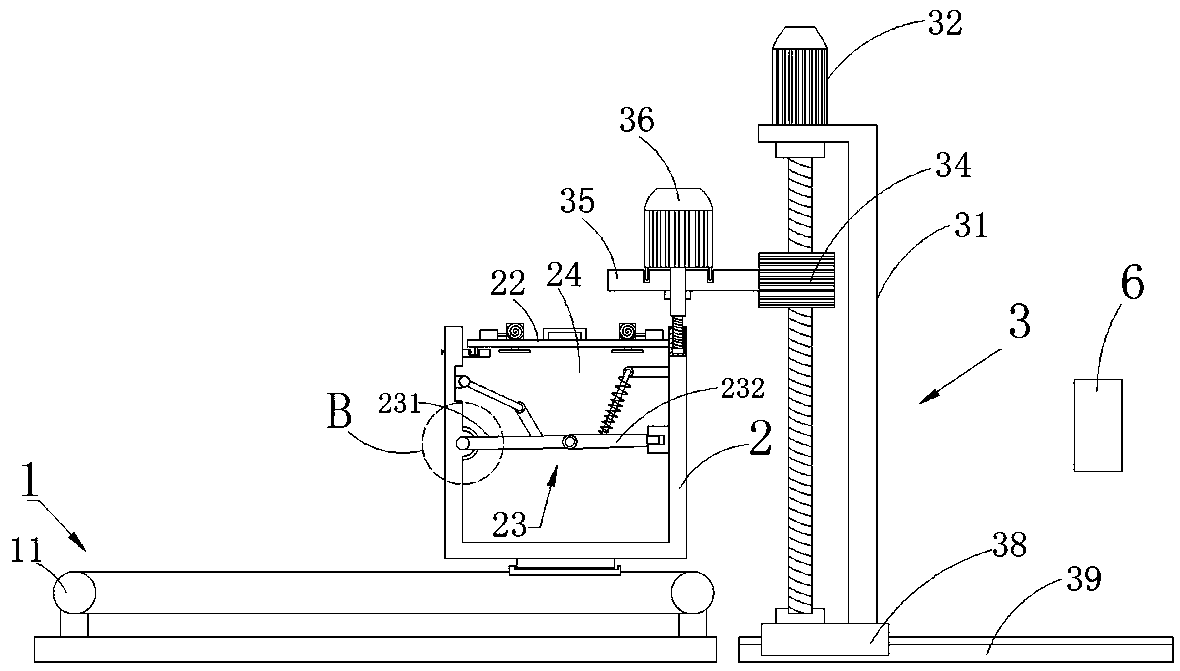

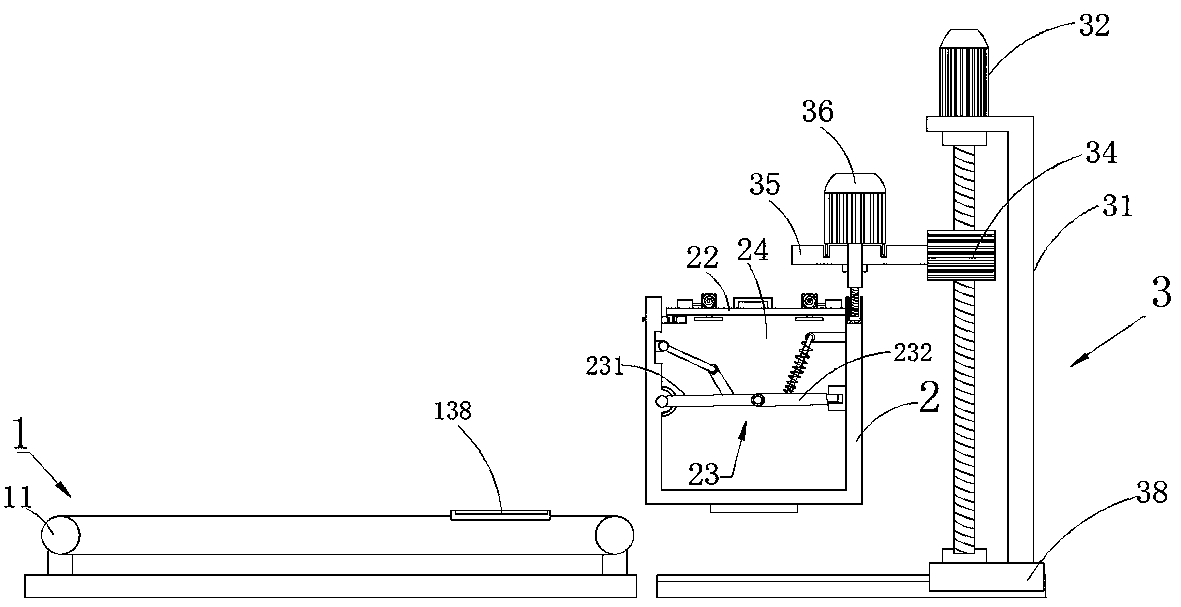

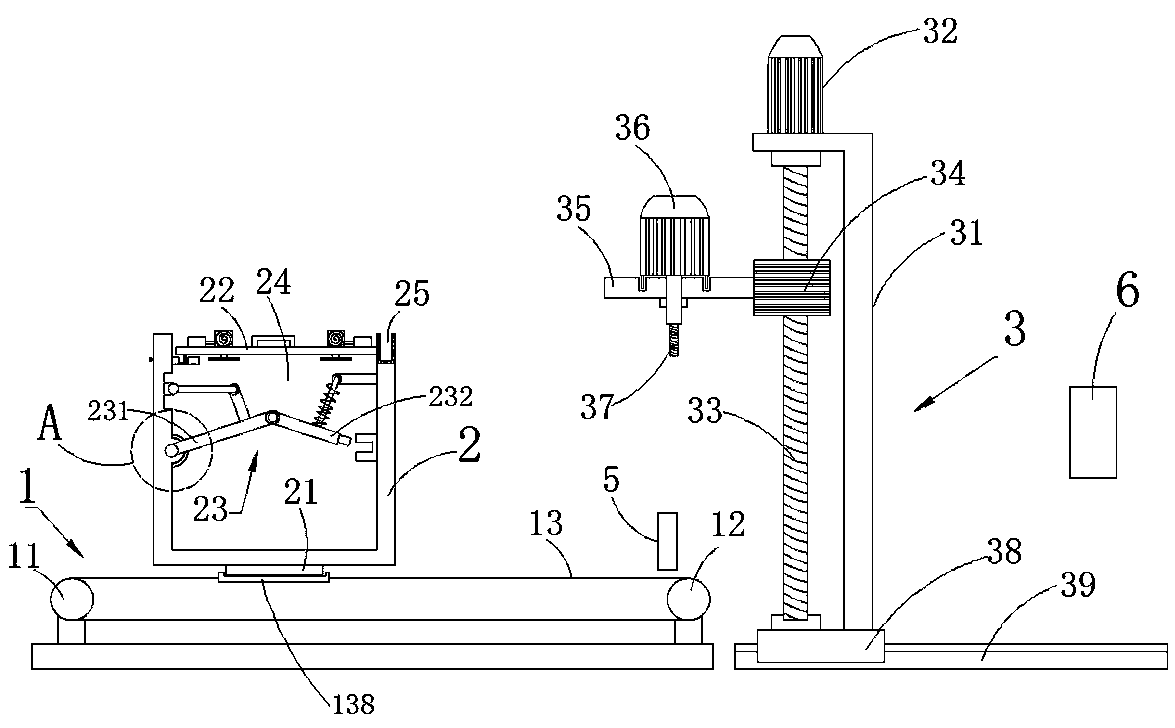

Surface machining treatment device for motor shaft of soybean milk machine and shaft machining technology

ActiveCN112091696ASave installation timeAutomatically removedManufacturing dynamo-electric machinesLarge fixed membersElectric machineryDrive motor

The invention relates to the field of high-precision transmission part machining, in particular to a surface machining treatment device for a motor shaft of a soybean milk machine and a shaft machining technology. The device comprise a case, a chuck, a driving motor, a cutting tool, a tool rest, a third hydraulic cylinder, a bar conveying mechanism, a movable plate and a case door. The bar conveying mechanism comprises a feeding box and a second hydraulic cylinder, a feeding port is formed in the feeding box, and bars discharged through the feeding port are aligned with the popup direction ofa piston rod of the second hydraulic cylinder. When the driving motor drives the chuck to rotate, the arrangement position of the driving motor is staggered with the center of the chuck. A support isfixedly connected to the movable plate, an arrangement ring is fixedly connected to the support, and the center of the arrangement ring is aligned with the center of the chuck. Multiple clamping cylinders are fixedly connected to the arrangement ring. The surface machining treatment device for the motor shaft of the soybean milk machine and the shaft machining technology have the effects of improving the automatic machining degree and improving the shaft machining efficiency.

Owner:宁波驶泰精密机械有限公司

Automatic feeding and expanding crystal machine for led lights

ActiveCN109860078BEasy to cutAutomatically removedSemiconductor/solid-state device manufacturingSemiconductor devicesLED lampWaste material

The invention discloses an automatic crystal cutting and expanding machine for LED lamps, which comprises a base, a placing platform for placing a raw material film, a crystal expanding part capable of moving up and down, an annular cutting part for cutting the raw material film, and a The film pressing part under the annular cutting part, the first driving part for driving the annular cutting part to move up and down, the second driving part for driving the crystal expanding part to move up and down, and the raw material film for heating The heating assembly; the annular cutting part is provided with an inclined cutting surface, and the bottom of the cutting surface is provided with a cutting knife; the present invention sets the inclined cutting surface so that the cutting knife set at the bottom of the cutting surface can better cut waste The film realizes the purpose of automatically removing the waste film, reduces the process, reduces the workload of the staff, and improves the production efficiency.

Owner:佛山市恩度照明电器有限公司

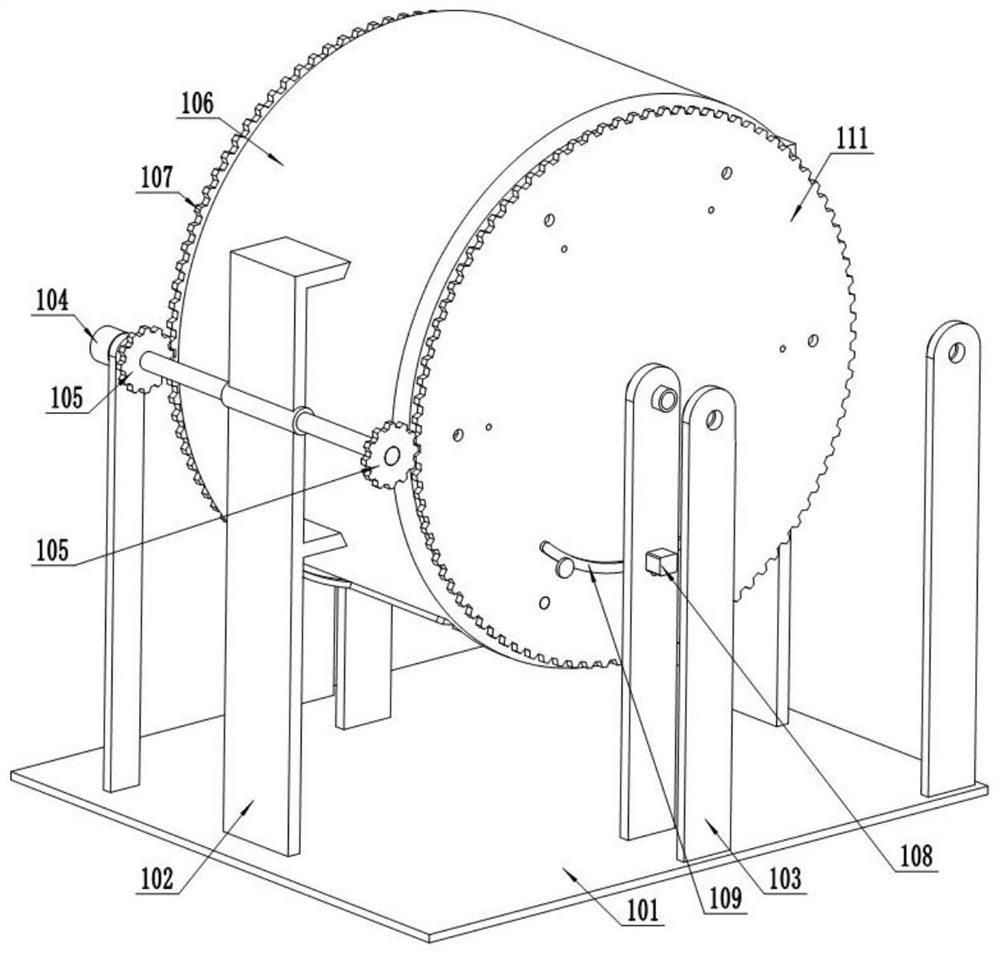

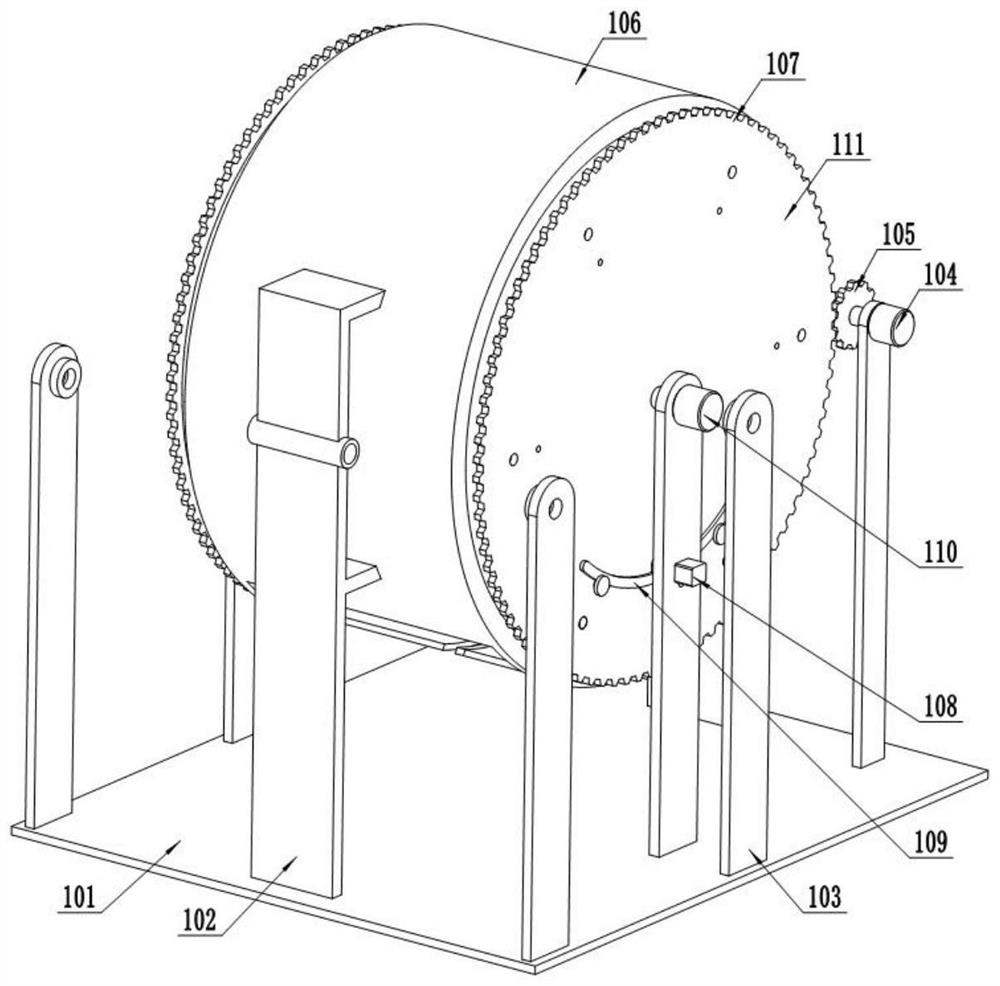

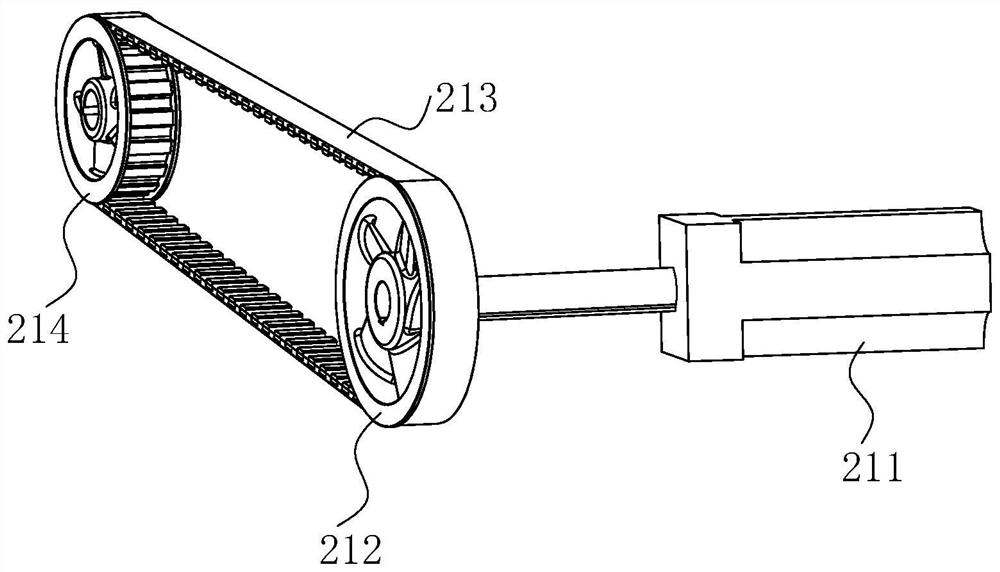

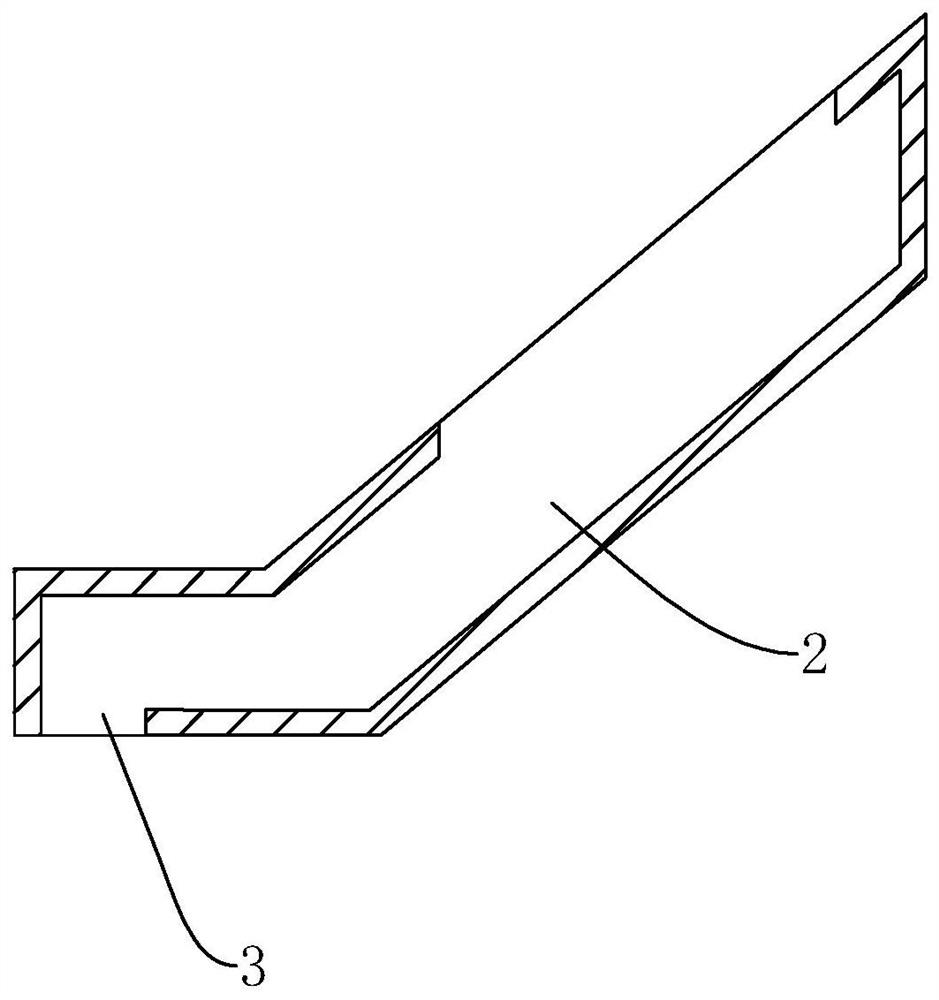

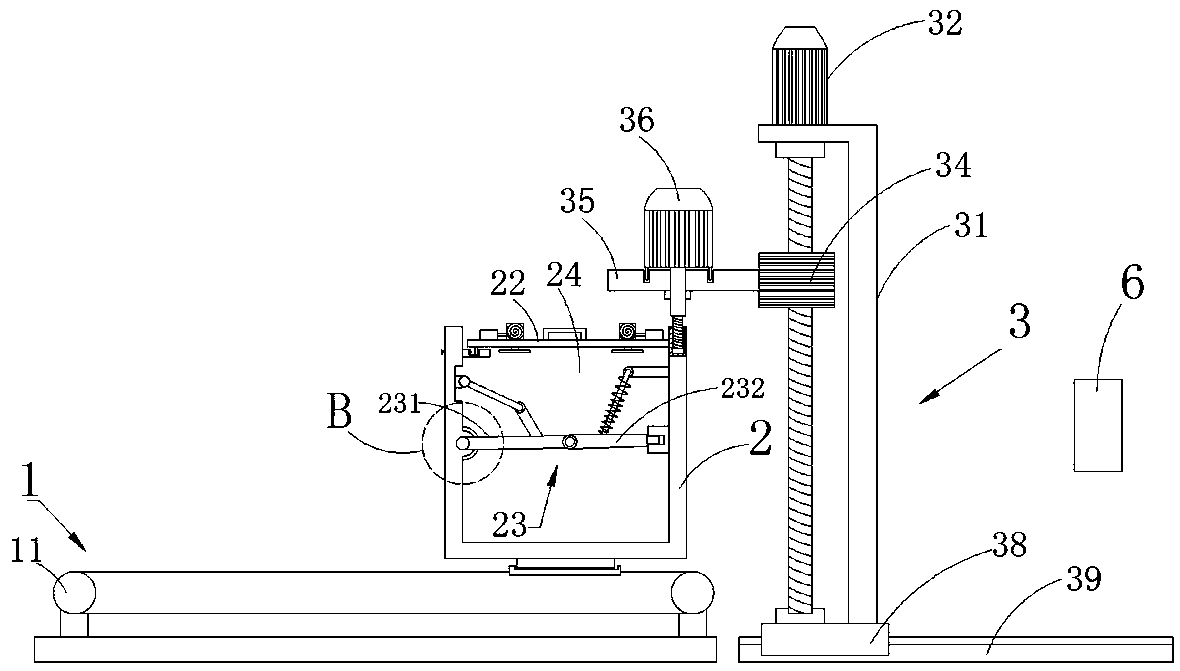

A hydrofluoric acid liquid transfer device and transfer method

ActiveCN109178876BPrevent leakageAddress shortcomings such as damageConveyor partsSprocketChain link

The invention relates to a hydrofluoric acid liquid transfer device and a transfer method. The device comprises a reciprocating conveying mechanism, a storage box, and a box taking mechanism, whereinthe storage box is used for loading hydrofluoric acid liquid, is borne on the reciprocating conveying device, and is driven to move by the reciprocating conveying device; the box taking mechanism takes down the storage box from the conveying tail end of the reciprocating conveying mechanism; the reciprocating conveying mechanism comprises a driving chain wheel arranged at the conveying initial end, a driven chain wheel arranged at the conveying tail end, and chains sleeving the driving chain wheel and the driven chain wheel; the chains comprise pin shafts, and links connected with all the pinshafts from two ends of the pin shafts; and two ends of the pin shafts extend out, and are fixedly sleeved with link blocks. The device needs no manual intervention in the transfer process, can monitor if hydrofluoric acid in the storage box is leaked in the transfer process, is provided with double layers of seals for effectively preventing leakage of the hydrofluoric acid liquid to the terminal,and solves the defect of possible damage of workers in traditional transfer of the hydrofluoric acid.

Owner:FUJIAN LONGDE NEW ENERGY CO LTD

Hydrofluoric acid liquid transfer device and transfer method

ActiveCN109178876APrevent leakageAddress shortcomings such as damageConveyor partsHydrofluoric acidEngineering

The invention relates to a hydrofluoric acid liquid transfer device and a transfer method. The device comprises a reciprocating conveying mechanism, a storage box, and a box taking mechanism, whereinthe storage box is used for loading hydrofluoric acid liquid, is borne on the reciprocating conveying device, and is driven to move by the reciprocating conveying device; the box taking mechanism takes down the storage box from the conveying tail end of the reciprocating conveying mechanism; the reciprocating conveying mechanism comprises a driving chain wheel arranged at the conveying initial end, a driven chain wheel arranged at the conveying tail end, and chains sleeving the driving chain wheel and the driven chain wheel; the chains comprise pin shafts, and links connected with all the pinshafts from two ends of the pin shafts; and two ends of the pin shafts extend out, and are fixedly sleeved with link blocks. The device needs no manual intervention in the transfer process, can monitor if hydrofluoric acid in the storage box is leaked in the transfer process, is provided with double layers of seals for effectively preventing leakage of the hydrofluoric acid liquid to the terminal,and solves the defect of possible damage of workers in traditional transfer of the hydrofluoric acid.

Owner:福建省龙德新能源有限公司

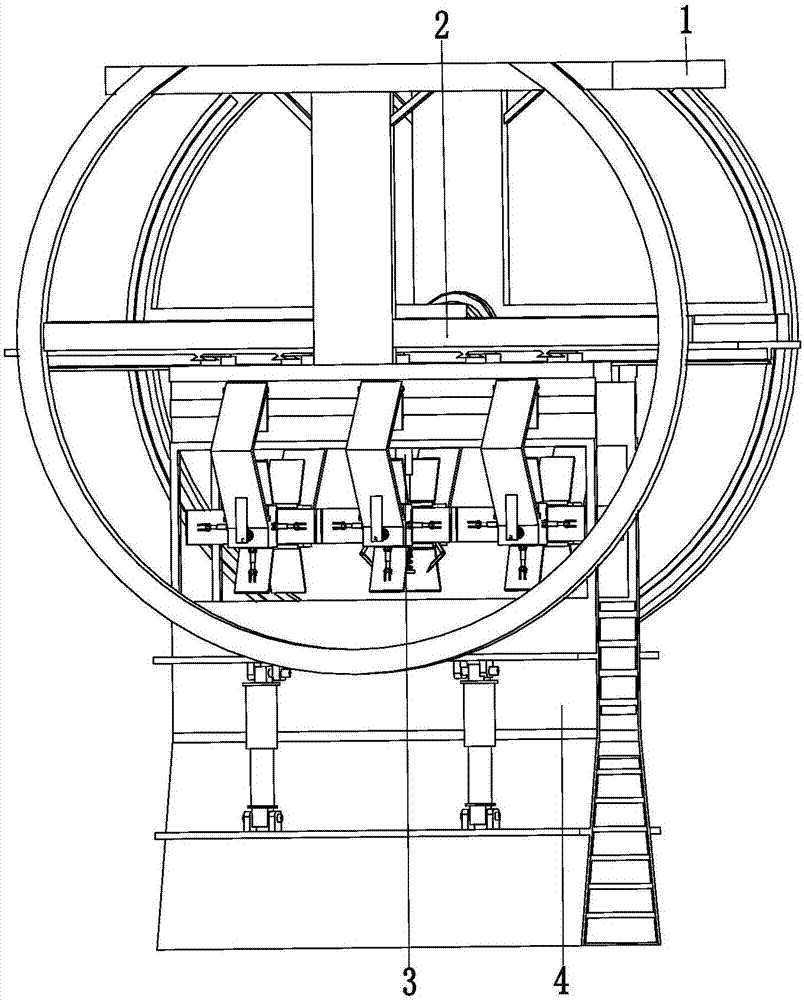

Three-hole water horse automatic collecting hanging bracket special for indicating road traffic driving route

InactiveCN107254857ARealize automatic collectionRealize functionTraffic signalsRoad signsEngineeringRoad traffic

The invention relates to a special three-hole water horse automatic collection hanger for indicating road traffic driving routes, which includes a top plate, a rotating device, an opening device and two clamping devices. The rotating device is installed on the bottom of the top plate, and the opening device is located Below the middle part of the device, and the opening device is connected with the bottom of the rotating device, and two clamping devices are symmetrically installed on the front and rear sides of the bottom of the rotating device. The present invention can solve the existing problems of low work efficiency and high labor intensity when manually collecting three-hole water horses. Larger models of three-hole water horses need several workers to operate together. Problems such as nearby dumping and cumbersome handling of the three-hole water tank; the functions of automatic collection and automatic opening and pouring of the three-hole water tank are realized, with high work efficiency and low labor intensity, and can be used for different types of three-hole water tanks. The advantages of collecting and pouring work, and being able to transport the three-hole water horse to a designated place for pouring work.

Owner:刘勇

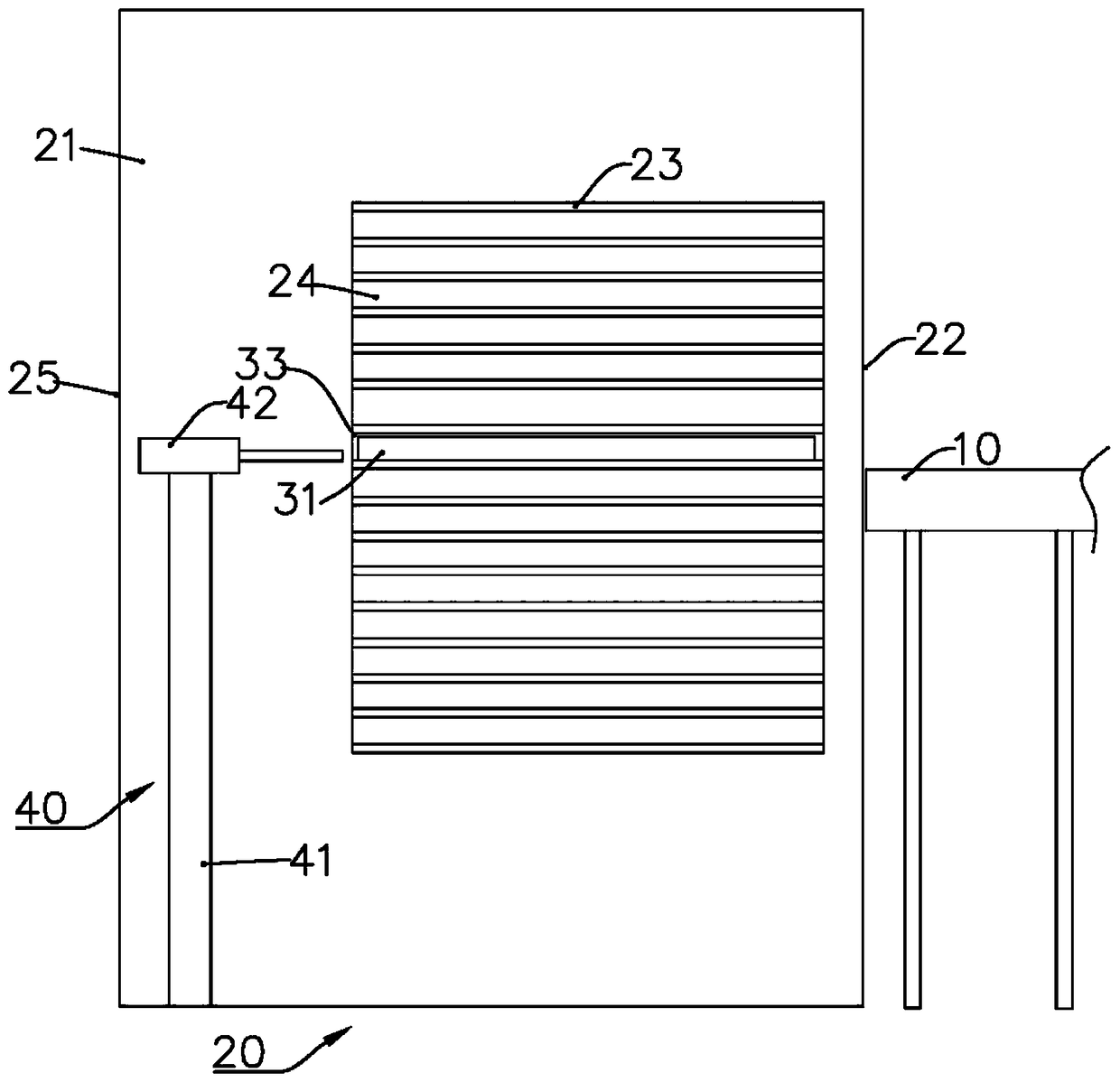

Anti-wrinkle flattening device for ironing clothes

InactiveCN112267281AReduce labor costsImprove ironing efficiencyIroning boardsTextiles and paperStructural engineeringMechanical engineering

The invention relates to the technical field of clothes, and discloses an anti-wrinkle flattening device for ironing clothes. The anti-wrinkle flattening device comprises supporting legs; a collectingchamber is fixedly connected to the upper sides of the supporting legs; an L-shaped rod is rotatably connected to the upper side of a first cylindrical block; a rotating block is rotatably connectedto the upper side of the L-shaped rod; a second moving rod is fixedly connected to the lower side of the first cylindrical block; the outer side of the second moving rod is slidably connected with a second rail; and the lower side of the second moving rod is fixedly connected with a paving block. According to the anti-wrinkle flattening device for ironing clothes, the first cylindrical block drives the second moving rod to move outwards, and the first cylindrical block drives the L-shaped rod to rotate, so that the rotating block is driven to rotate, the square first cylindrical block is driven by a first sliding block to move outwards at the same time, and therefore the clothes are flattened. By means of the structure, the effects that the labor cost is reduced, the ironing efficiency ishigh, automatic flattening is achieved, the effect is good, and new wrinkles cannot be generated are achieved.

Owner:高宾

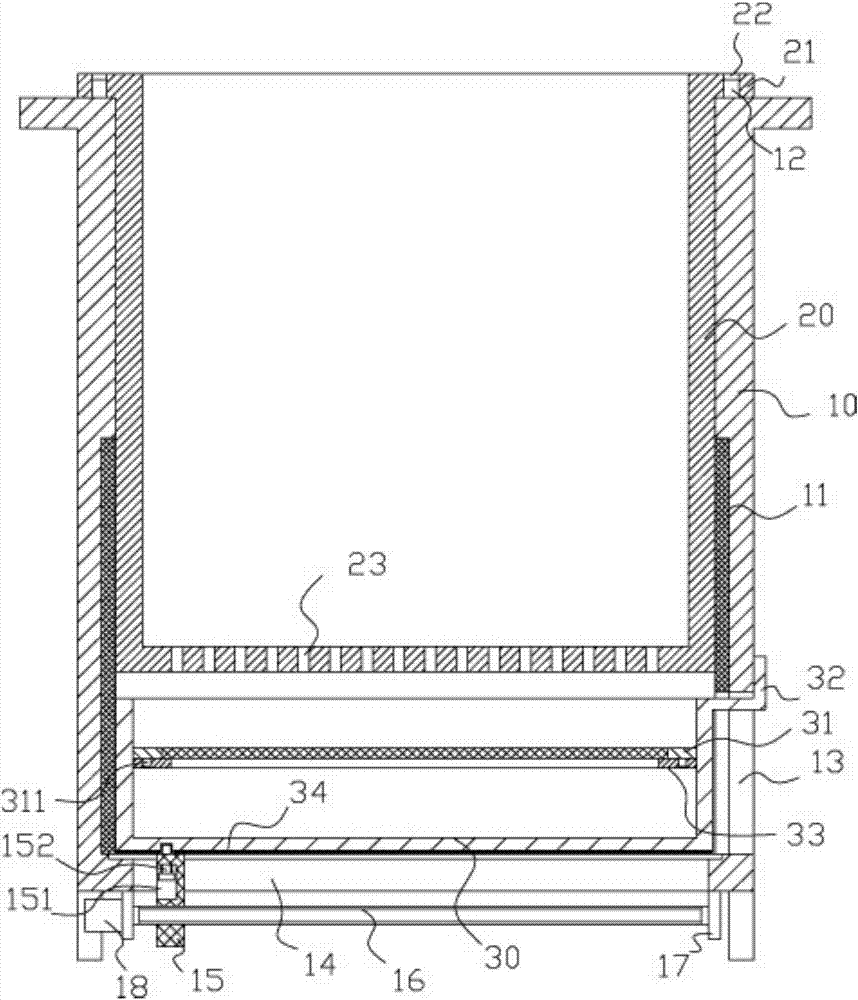

Polystyrene vacuum automatic packaging forming machine

ActiveCN111674617AShorten the timeImprove work efficiencyPackaging under vacuum/special atmosphereWrapper twisting/gatheringPolystyreneAir pump

The invention discloses a polystyrene vacuum automatic packaging forming machine, and belongs to the technical field of vacuum packaging. The polystyrene vacuum automatic packaging forming machine comprises a box body, an air extracting pump and a hot-pressing sealing machine, wherein a vacuum chamber is arranged on the box body, and the air extracting pump is connected with the box body through afirst connecting pipe; and the polystyrene vacuum automatic packaging forming machine further comprises an air cylinder, the air cylinder and the air extracting pump are connected through a second connecting pipe, a piston plate is slidably connected into the air cylinder, the lower end of the piston plate is fixedly connected with a connecting plate, the connecting plate is connected to the aircylinder and the box body in a sliding mode, the hot-pressing sealing machine is connected to the bottom end of the connecting plate, a conveying and placing plate is connected into the box body in asliding mode, and the conveying and placing plate is connected with the connecting plate. According to the polystyrene vacuum automatic packaging forming machine, a polystyrene packaging bag is sealedwhile vacuum extracting is conducted in a vacuum room, and after sealing is completed, the polystyrene packaging bag is automatically moved out.

Owner:湖南天阁食品有限公司

Device for stripping sheathing on unbonded post-tensioning tendons

ActiveUS8443520B2Easily falls awaySmooth rotationMetal working apparatusAnchoring boltsEngineeringMechanical engineering

Owner:VIERECK KYLE +1

Polystyrene vacuum automatic packaging molding machine

ActiveCN111674617BShorten the timeImprove work efficiencyWrapper twisting/gatheringPackaging under vacuum/special atmosphereMolding machinePolystyrene

The invention discloses a polystyrene vacuum automatic packaging forming machine, which belongs to the technical field of vacuum packaging. The polystyrene vacuum automatic packaging molding machine includes a box body, an air pump, and a heat-press sealing machine. The box body is provided with a vacuum chamber. The air cylinder and the air pump are connected through a second connecting pipe, a piston plate is slidably connected in the air cylinder, and a connecting plate is fixedly connected to the lower end of the piston plate, and the connecting plate is slidably connected to the air cylinder and the box body, and the heat-press sealing The machine is connected to the bottom end of the connection plate, and the transmission and placement plate is slidably connected in the box, and the transmission and placement plate is connected with the connection plate. This device can vacuum the polystyrene packaging bag while vacuuming the vacuum chamber. Sealing, and after the sealing is completed, the polystyrene packaging bag is automatically removed.

Owner:湖南天阁食品有限公司

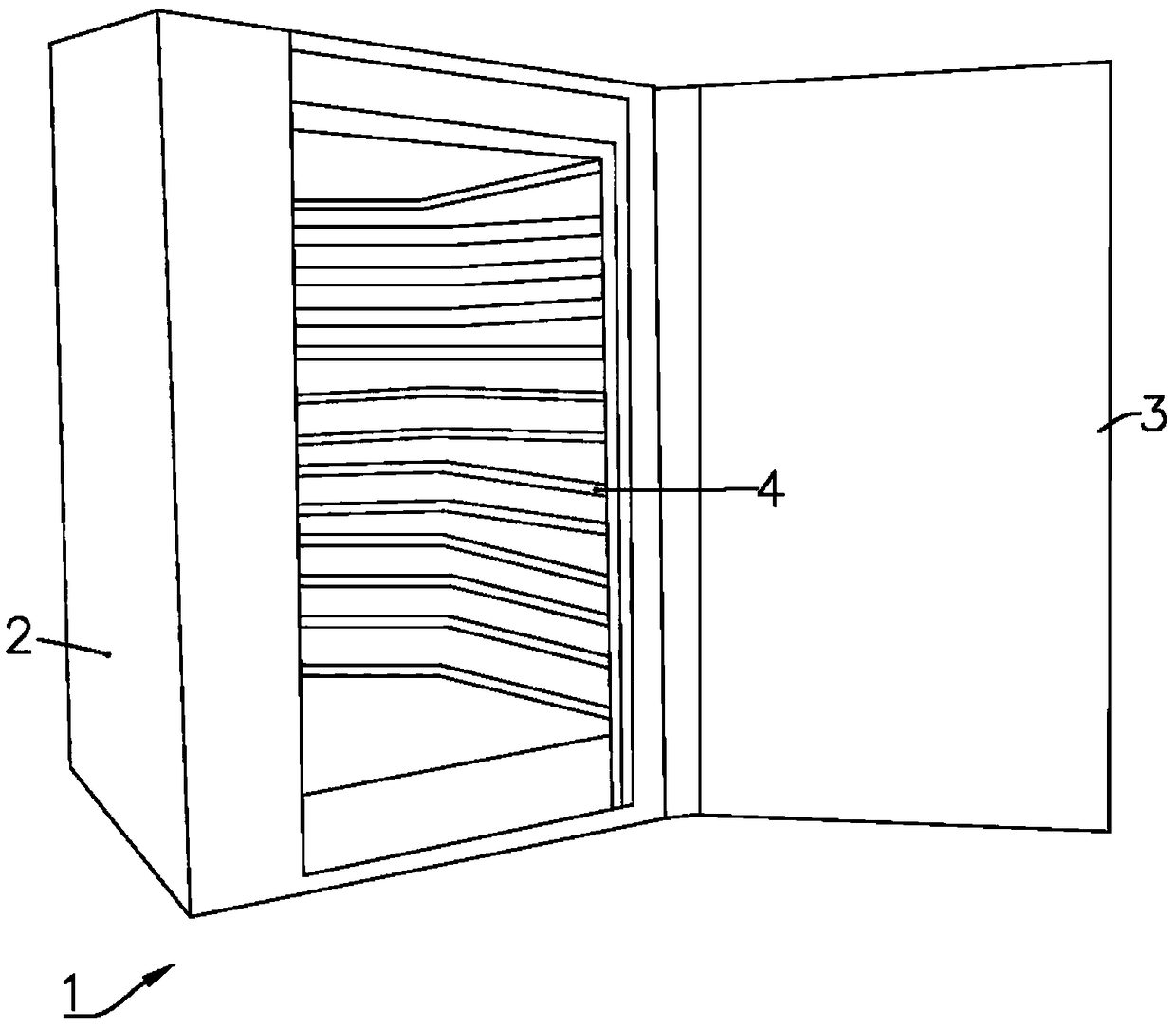

Sports equipment intelligent storage cabinet

The invention discloses a sports equipment intelligent storage cabinet which structurally comprises a storage cabinet body, a servo motor, a bearing, a controller and a built-in groove are arranged on the storage cabinet body, the servo motor is fixedly connected to the left side of the interior of the storage cabinet body, the bearing is fixedly connected to the interior of the storage cabinet body, and located on the left side of the built-in groove, the controller is fixedly connected to the middle of the right end of the storage cabinet body, and the built-in groove is located in the storage cabinet body; a screw rod is arranged at the left end of the bearing, a password input key and a fingerprint collector are arranged on the controller, and the password input key is fixedly connected to the middle of the controller. According to the equipment storage cabinet, stored equipment can be automatically moved out from the interior of the storage cabinet, the situation that the equipment is inconvenient to put into the storage cabinet due to the fact that the equipment is too large is prevented, the probability that the equipment is lost by a storer is reduced, and the prompting effect of the storage cabinet on equipment storage is improved.

Owner:扬州纵横体育器材科技有限公司

Cleaning system and method for disassembling cleaning unit of cleaning system

PendingCN114515129AAutomatically removedEasy to removeCarpet cleanersFloor cleanersEngineeringStructural engineering

The invention discloses a cleaning system and a dismounting method of a cleaning unit of the cleaning system, the cleaning system comprises a base station, the base station is provided with an accommodating space, and the accommodating space is internally provided with a dismounting unit; the cleaning robot is selectively contained in the containing space, and the cleaning robot comprises a cleaning body and a cleaning unit detachably installed on the cleaning body; wherein a fixing block is arranged on the side wall of the cleaning unit, a first buckle is arranged on the cleaning body, a second buckle is arranged on the detaching unit, the first buckle is suitable for being connected with the fixing block in a clamped mode to assemble the cleaning unit, and the second buckle is suitable for being connected with the fixing block in a clamped mode to detach the cleaning unit. And the second buckle is suitable for extending between the first buckle and the fixing block to unlock the clamping connection of the first buckle and the fixing block, so that the automation and the convenience of the cleaning system are improved.

Owner:SHEN ZHEN 3IROBOTICS CO LTD

AUtomatic paper feeder with paper feeding and running mechanism

Owner:AVISION PRECISION IND (SUZHOU) CO LTD

Electric vacuum cleaner

InactiveCN101238961BEasy to operateAutomatically removedSuction nozzlesElectric equipment installationEngineeringVacuum cleaner

An electric dust collector is provided; an electric brush, which is internally mounted in a sucking device, is coated with a sheet to clean, such a structure is beneficial to expand uses of the electric dust collector. In order to coat the sheet (50) over circumference of a rotary brush (25), the rotary brush (25) can be rotated toward a stated direction at a stated rotating speed through a brushmotor (44). Besides, for the purpose of disassembling the sheet (50) coated on the rotary brush (25), the rotary brush (25) is enforced to perform the positive rotation and inverse rotation. Suction of the electric dust collector is enhanced to make use of the suction of an electric blower fan to automatically unlock the sheet. The invention can provide an electric dust collector which is able todisassemble the sheet (50) coated around the rotary brush (25) without the contact of user, and has excellent performance and great convenience.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com