AUtomatic paper feeder with paper feeding and running mechanism

A technology of paper feeding mechanism and driving device, which is applied in office printing equipment, printing, etc., and can solve problems such as unsmooth scanning process, unsmooth removal, and paper retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Composition of the present invention

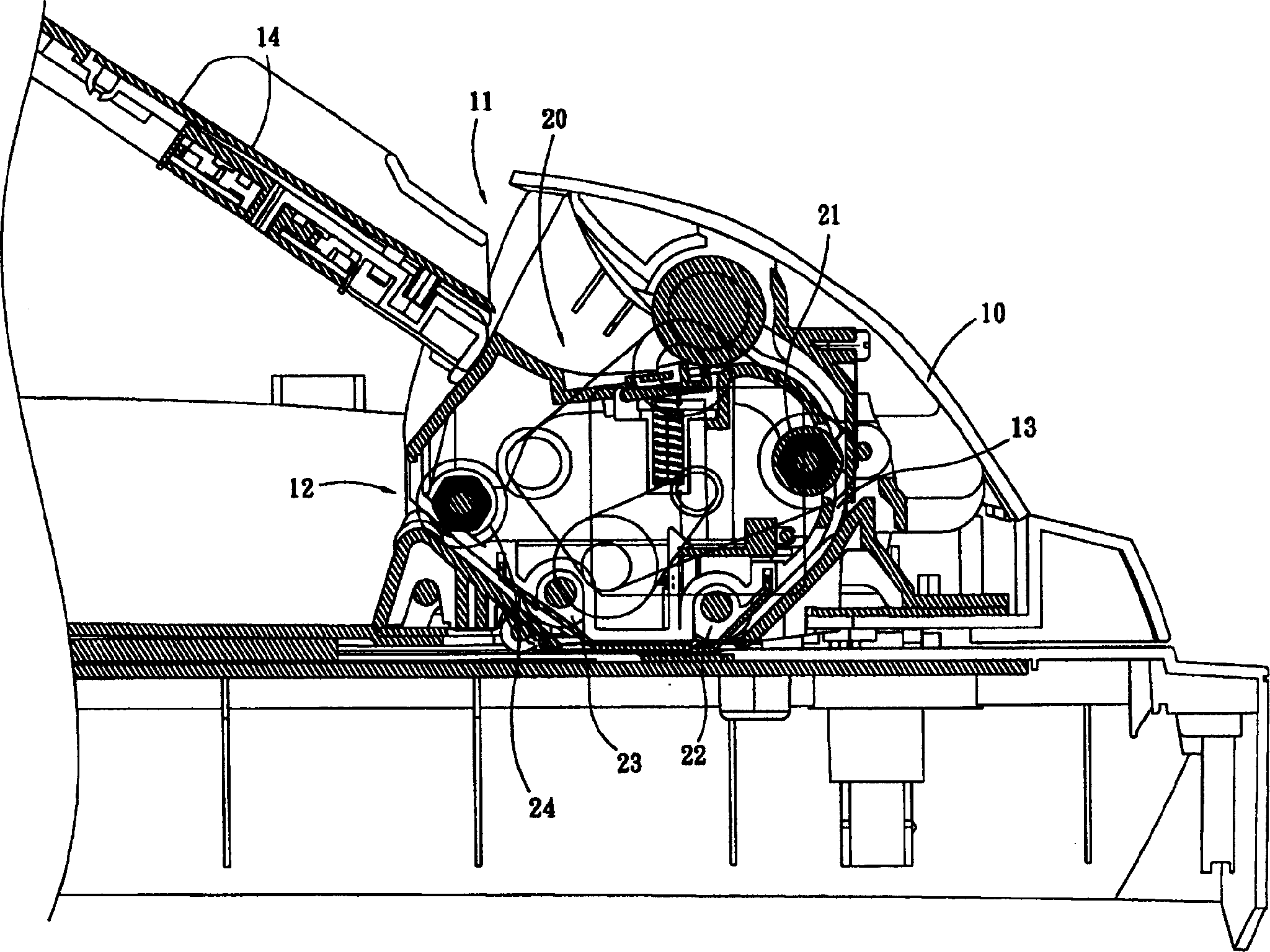

[0026] figure 1 Shown is a schematic diagram of the mechanism of the automatic paper feeding device. The figure discloses a main body 10 and a paper ejecting / feeding mechanism 20 assembled in the main body 10 .

[0027] Ontology 10 Mechanism

[0028] exist figure 1 Among them, the main body 10 is provided with a paper input end 11 and a paper output end 12, and a paper feeding channel 13 is arranged between the paper feeding end 11 and the paper output end 12, and the paper feeding channel 13 is U-shaped. A cardboard 14 is assembled on one side of the paper feeding end 11 for placing paper, which is not shown in the figure. In this paper, the scanning area S is defined as the area for scanning documents.

[0029] Mechanism of paper ejecting / feeding mechanism 20

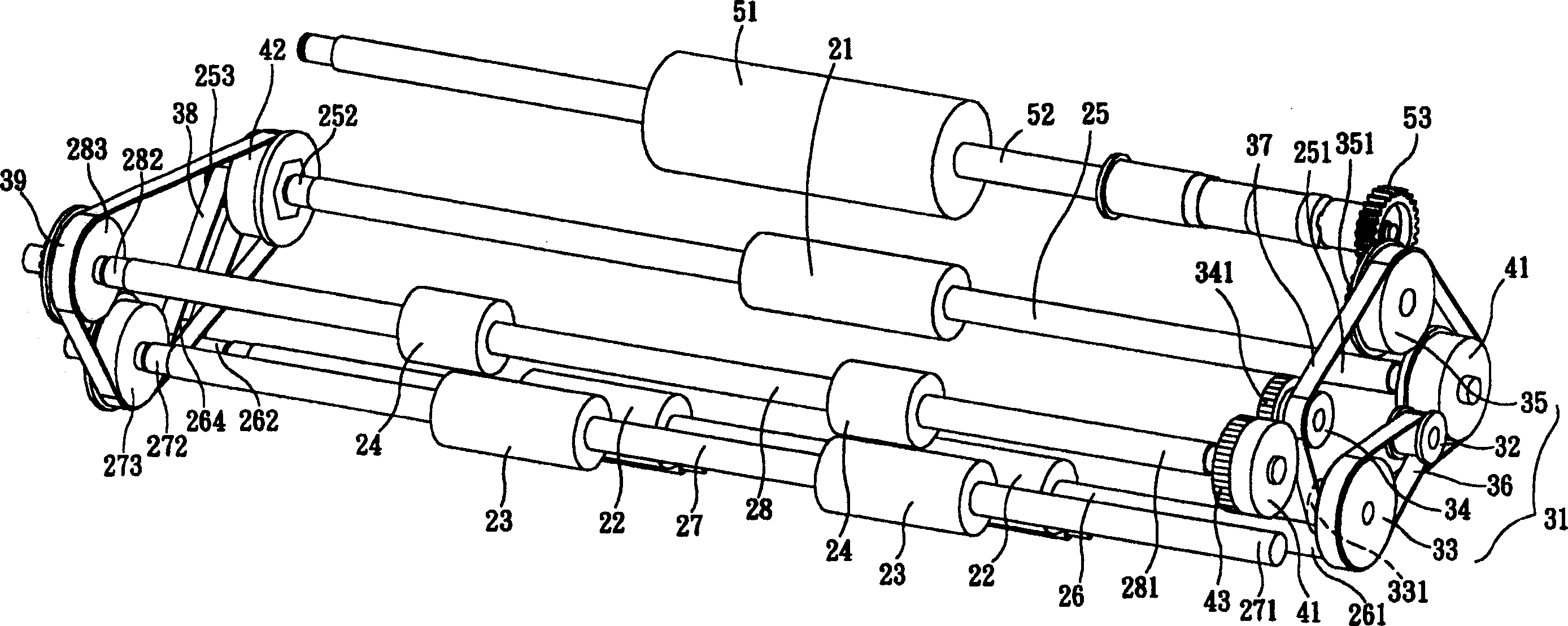

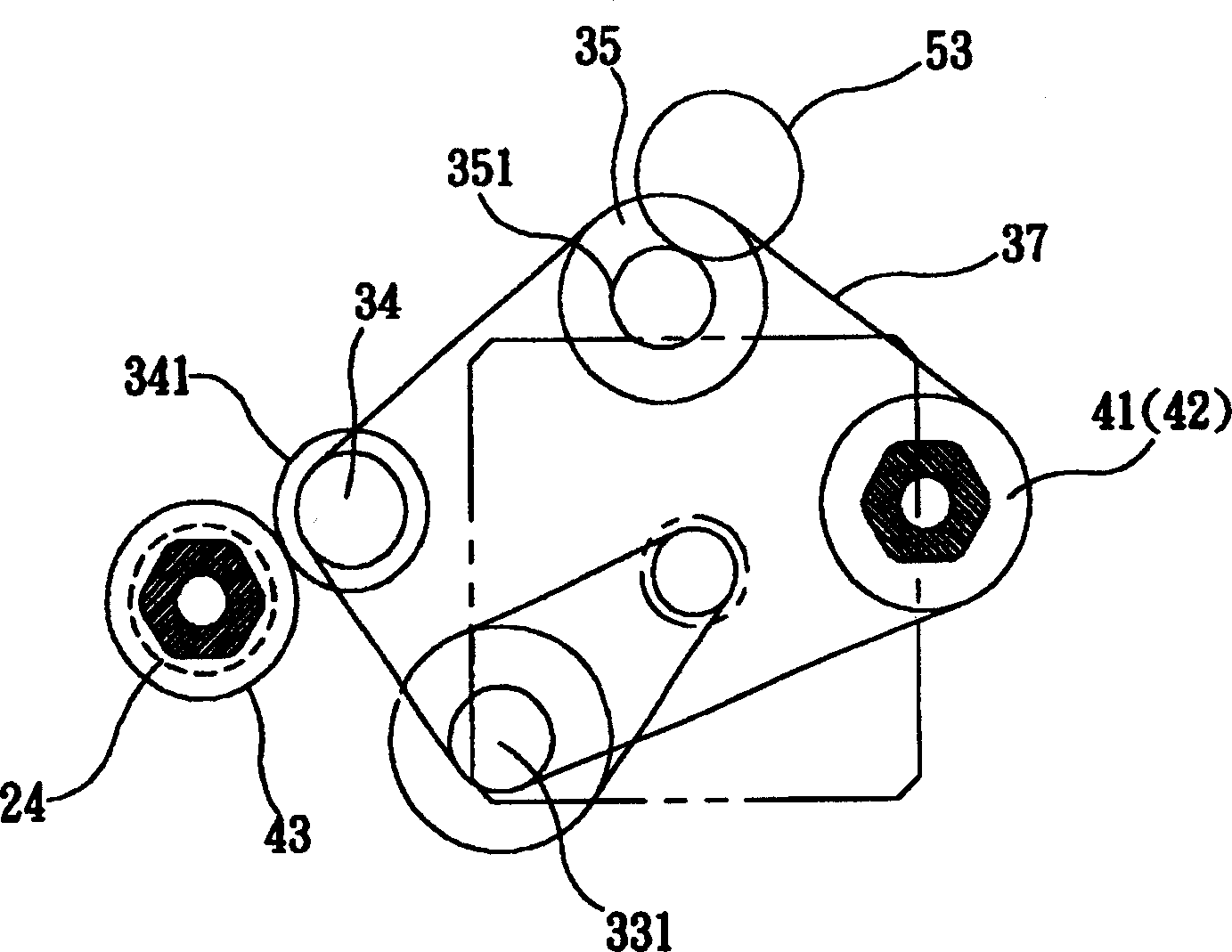

[0030] figure 2 It is an external view of the paper ejection / feeding mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com