Labeling machine

A labeling machine and labeling board technology, applied in labeling machines, labels, packaging, etc., can solve the problems of low work efficiency, low degree of automation, and unguaranteed labeling quality, and achieve the advantages of convenient operation and increased adsorption force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-6 , to further describe this application in detail.

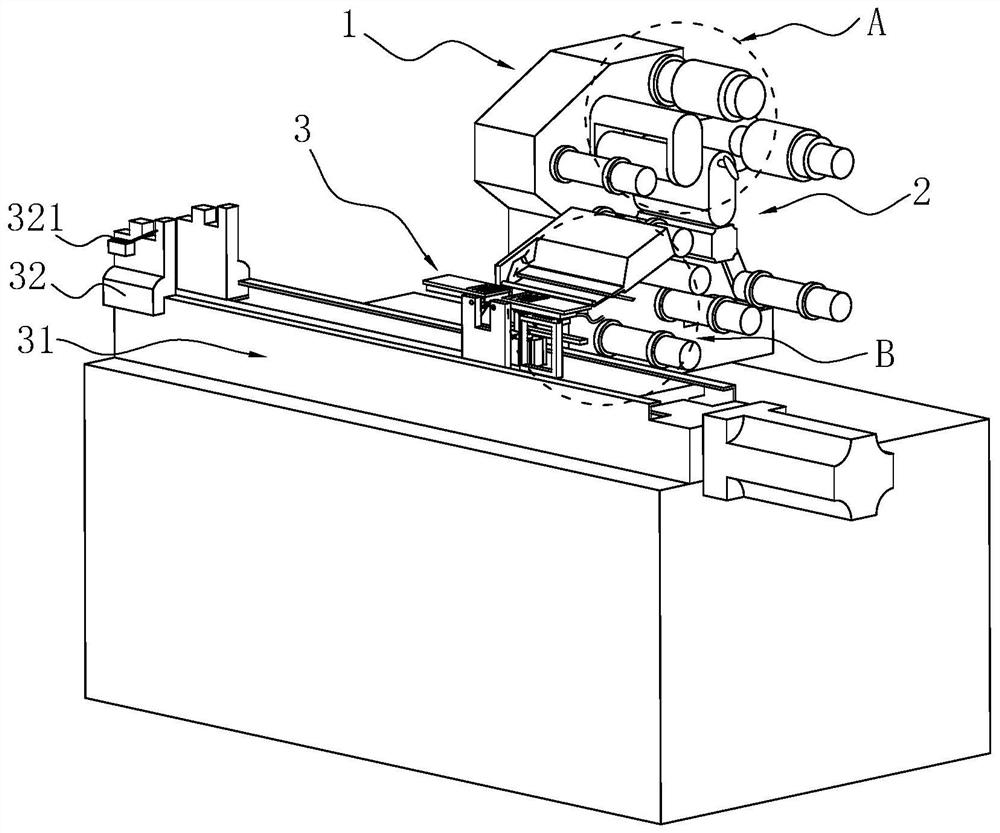

[0040] The embodiment of the application discloses a labeling machine. refer to figure 1 , The labeling machine includes a labeling machine body 1, and the labeling machine body 1 is fixedly installed on the workbench. The labeling machine body 1 is provided with a labeling device 2 and a bonding device 3 .

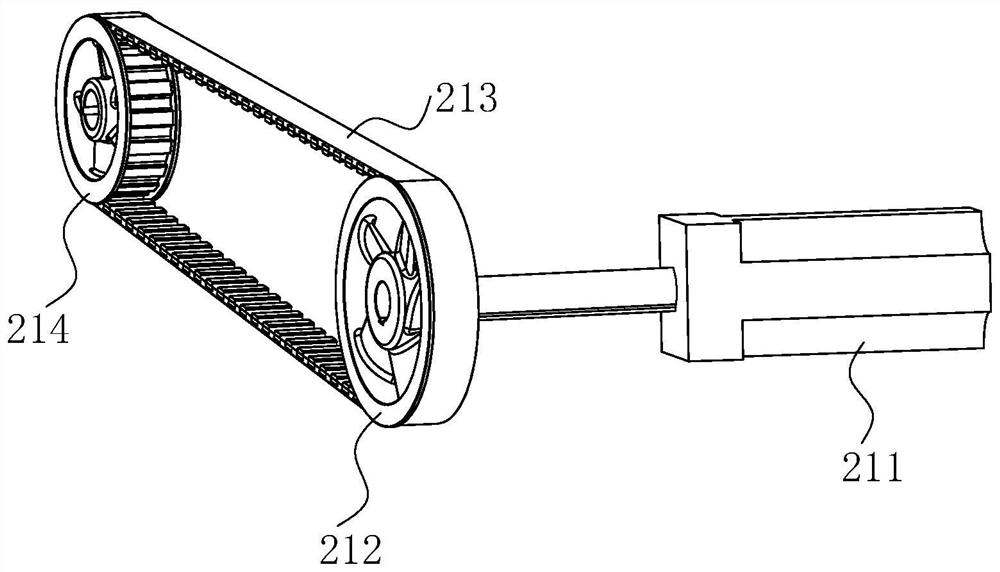

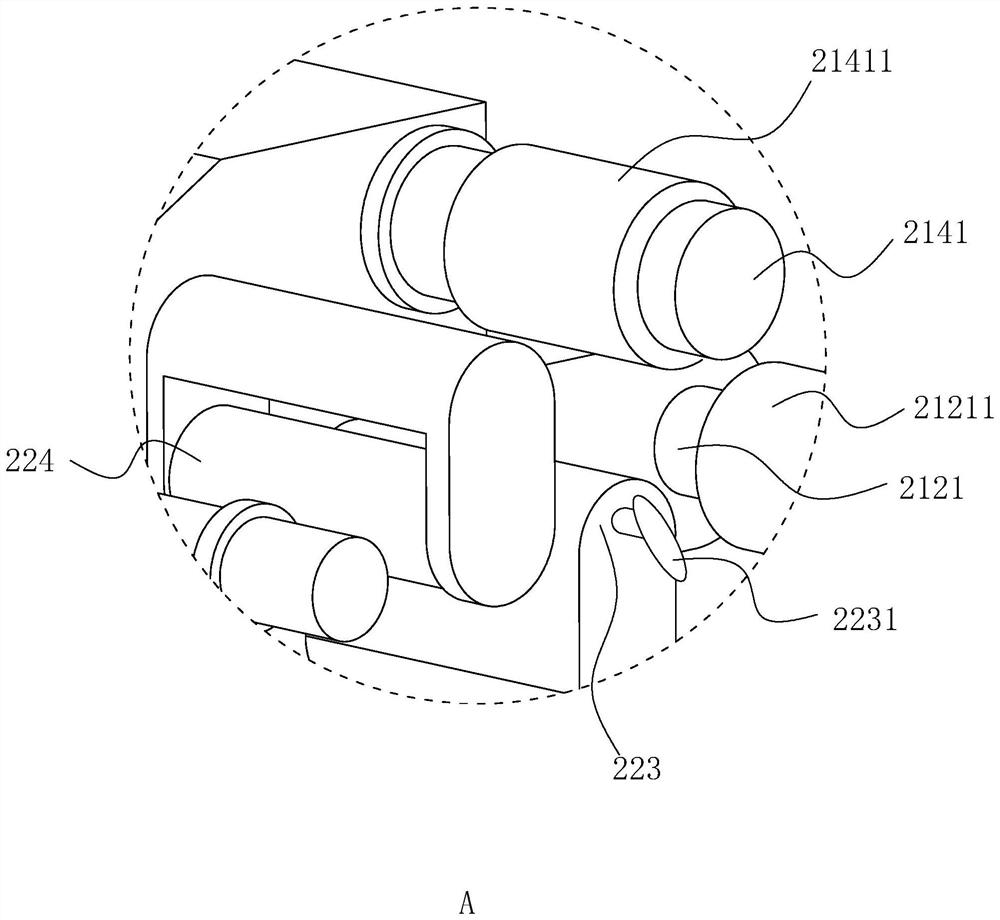

[0041] The marking device 2 includes a driving mechanism 21 and a marking mechanism 22 . refer to figure 1 and figure 2, the driving mechanism 21 includes a first motor 211, the first motor 211 is fixedly installed on the side wall of the labeling machine body 1, the rotating shaft of the first motor 211 extends into the labeling machine body 1, and the first motor 211 is connected with a transmission mechanism. The transmission mechanism includes a driving gear 212 , a conveyor belt 213 and a driven gear 214 . The driving gear 212 is spline connected to the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com