Clamping device

A clamping device and clamping element technology, which is applied in the field of workpiece clamping devices, can solve problems such as workpiece damage and the tool cannot reach the position of the workpiece, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

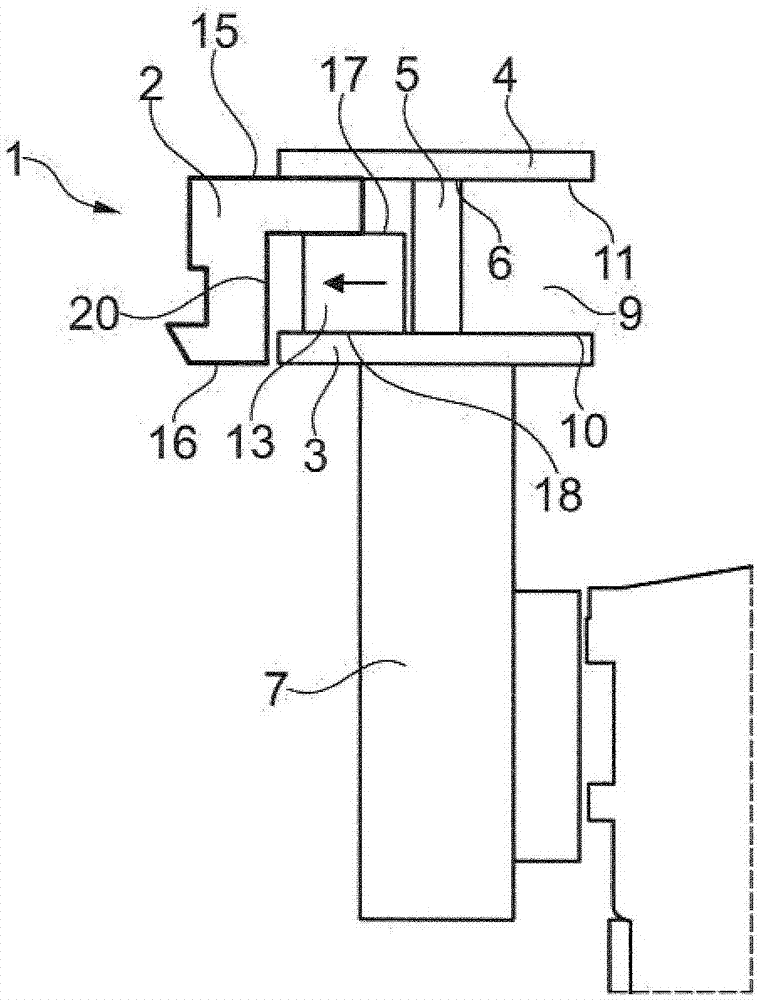

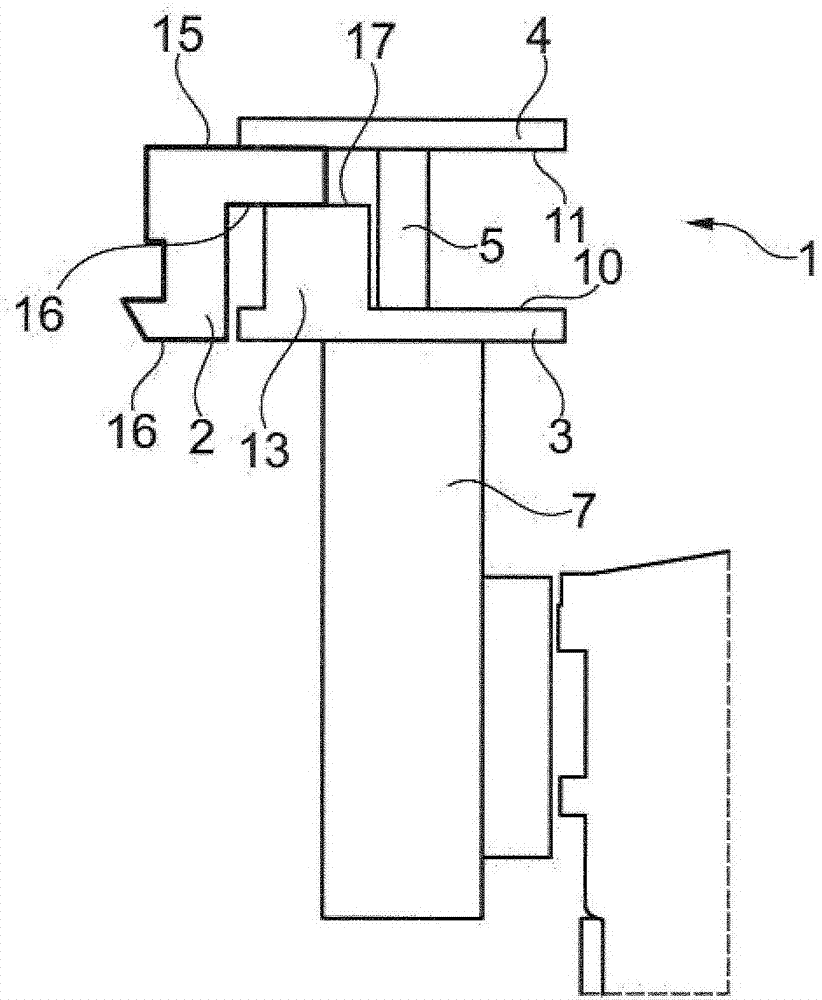

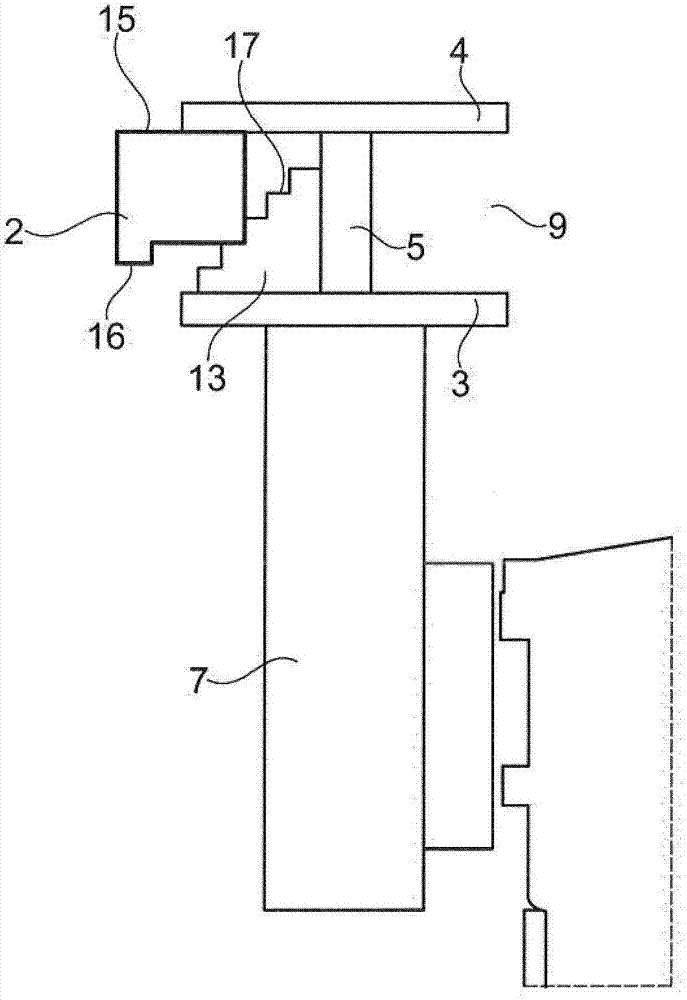

[0061] figure 1 A clamping device 1 is shown for clamping a workpiece 2 made of wood, plastic or similar material for processing it in a processing device.

[0062] The clamping device 1 has a lower clamping element 3 and an upper clamping element 4 . The upper clamping element 4 is adjustable in height relative to the height-immovable lower clamping element 3 . Optionally, the height of the lower element 3 can also be adjusted.

[0063] The upper clamping element 4 is flat or approximately flat, and is fixedly connected to the positioning rod 5 . Such as figure 1 As shown, the connection is made at the upper end 6 of the positioning rod 5 . Connections can also be made in other ways if necessary. A more favorable solution is that the connection between the upper clamping element 4 and the positioning rod 5 is a threaded connection. In addition, the positioning rod 5 and the upper clamping element 4 can also form an integral part.

[0064] Such as figure 1 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com