Automatic blanking wafer expander for LED lamps

A technology of automatic blanking and LED lights, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increasing the workload of the staff, unable to remove the raw material film, affecting production efficiency, etc., to increase heat conduction and heat dissipation The effect is conducive to heat conduction and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

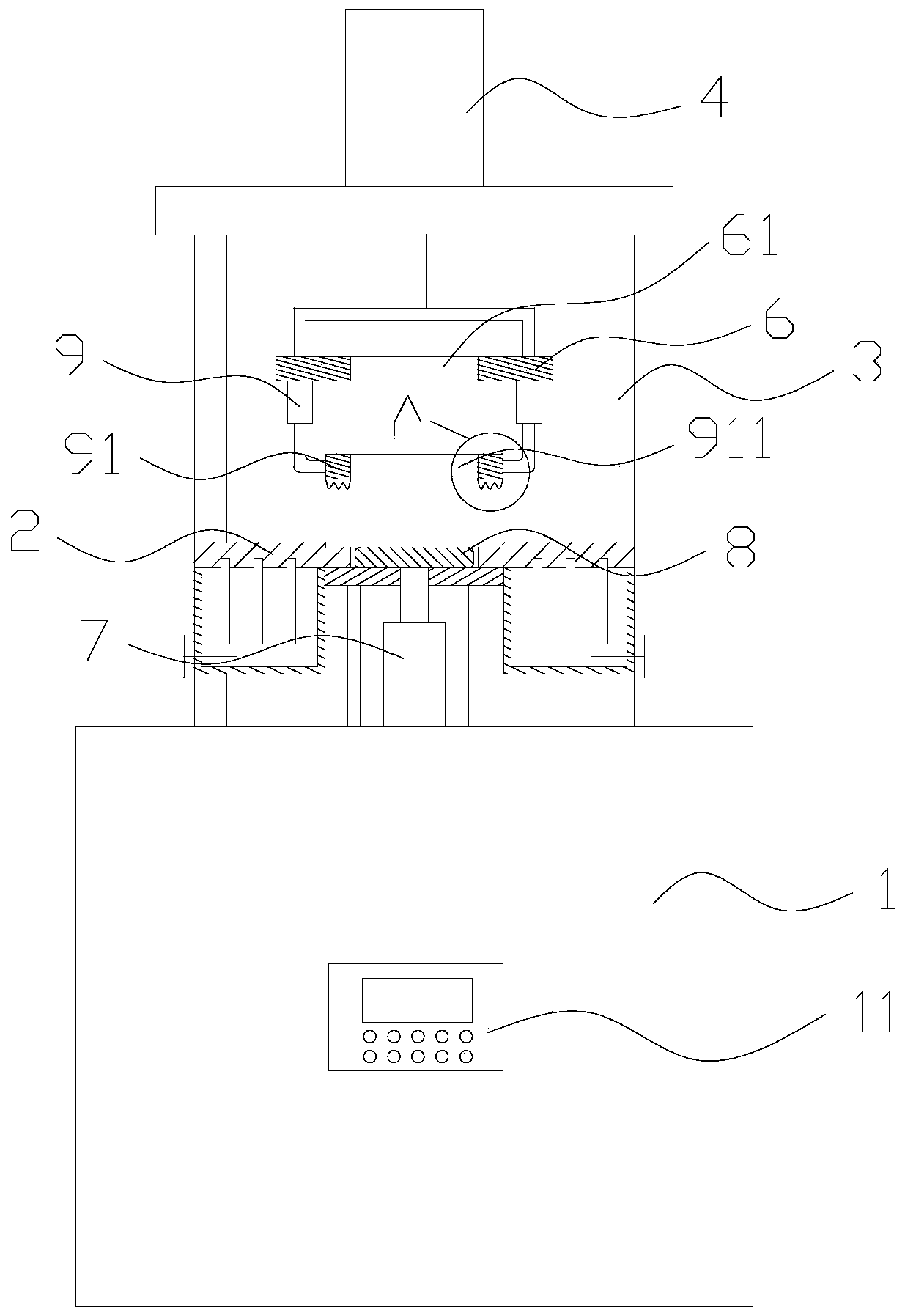

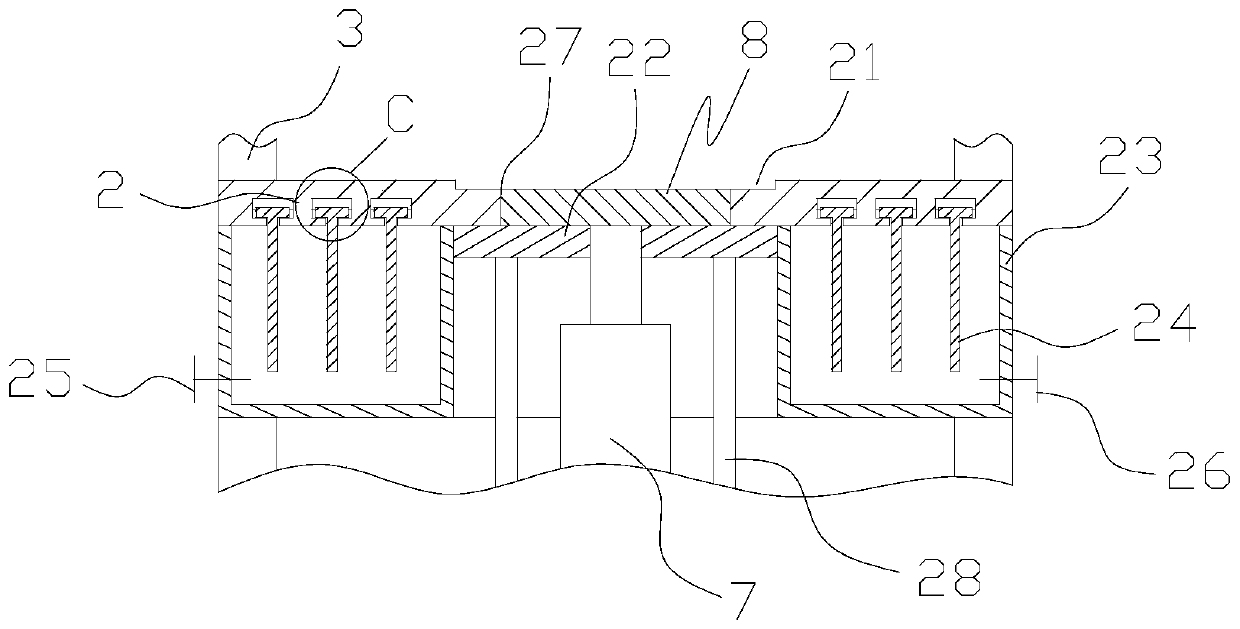

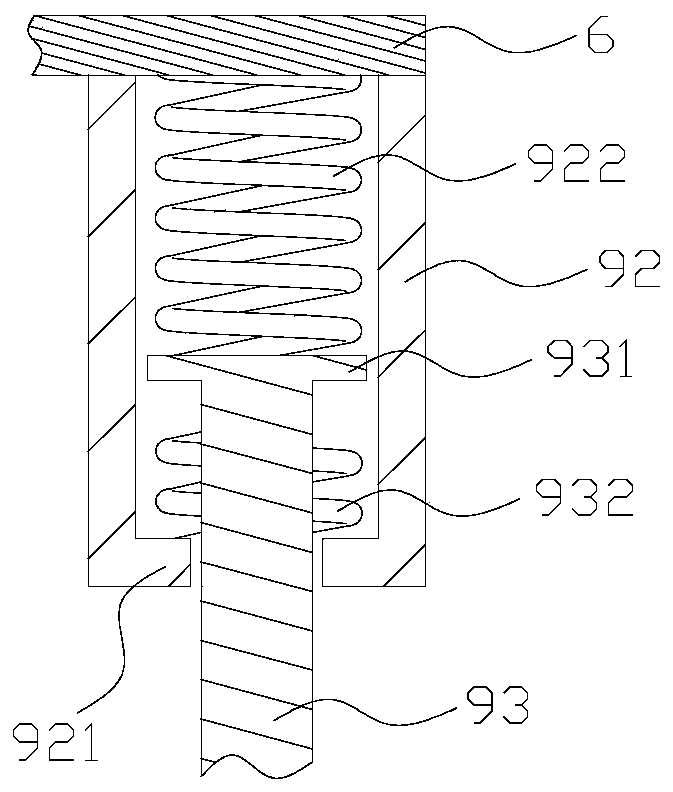

[0026] Such as Figure 1 to Figure 11 As shown, an automatic unloading crystal expansion machine for LED lamps includes a base 1, a placement platform 2 for placing a raw material film 99, a crystal expansion part 8 that can move up and down, and a circular cutting device for cutting the raw material film 99. Part 6, a film-pressing part 91 arranged below the annular cutting part 6, a first driving part 4 for driving the annular cutting part 6 to move up and down, a second driving part for driving the crystal expanding part 8 to move up and down The driving element 7 and the heating assembly for heating the raw material film 99; the first driving element and the second drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com