Automatic bean curd slitting device

An automatic and strip cutting technology, which is applied in metal processing and other directions, can solve the problems of danger, uneven cutting of tofu, etc., and achieve the effect of convenient use of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

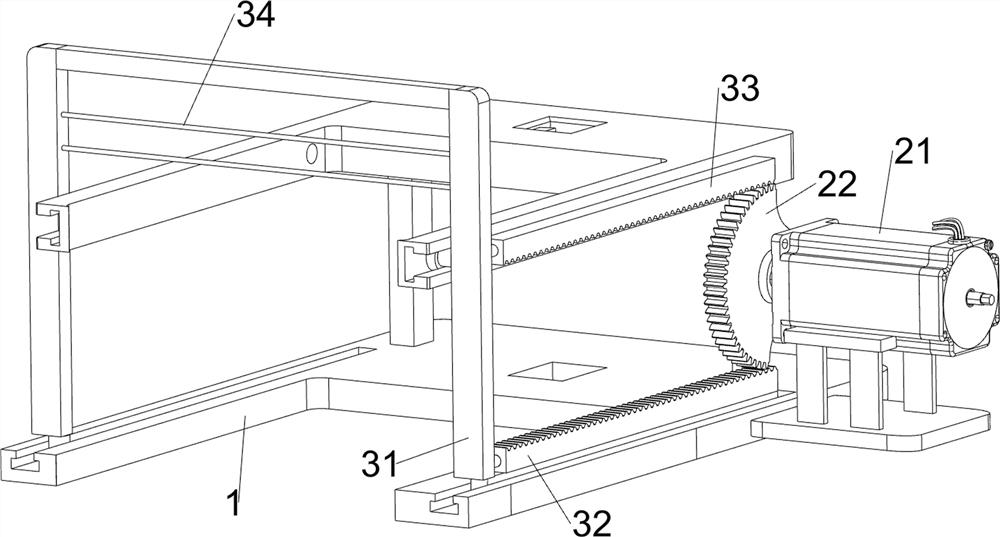

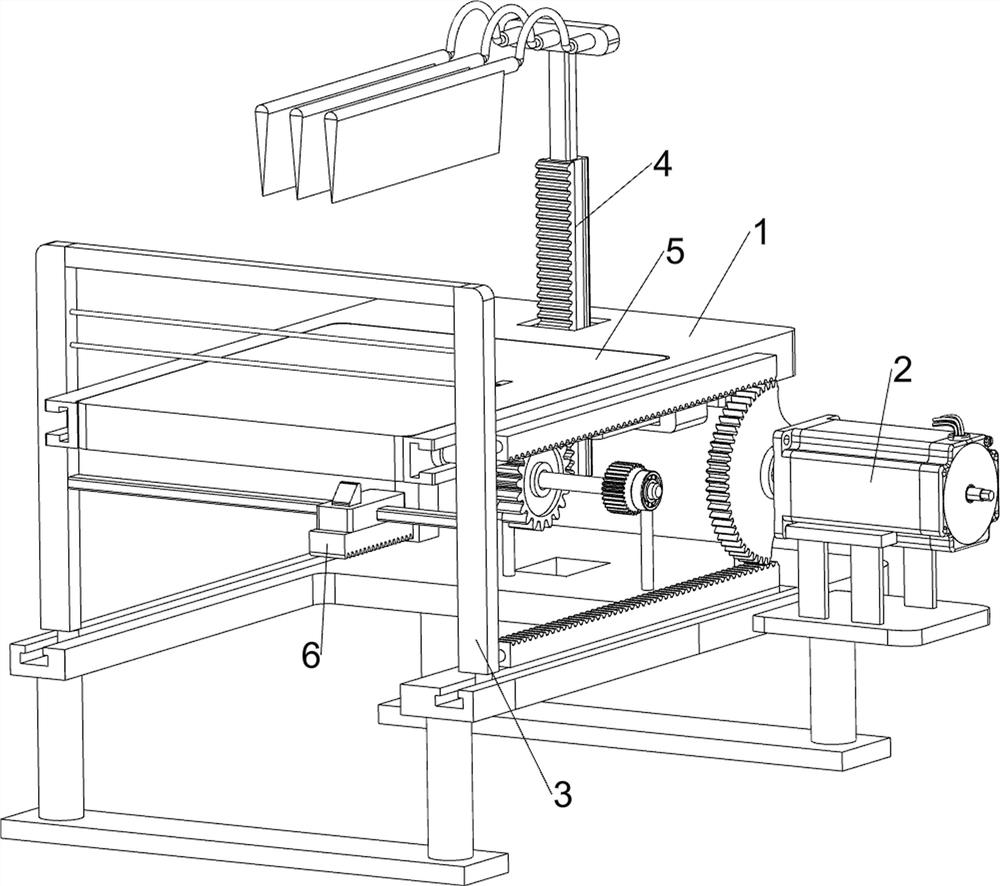

[0023] A kind of tofu automatic cutting device, such as Figure 1-Figure 4 As shown, it includes a bracket 1, a power component 2, a transverse cutting component 3 and a longitudinal cutting component 4. The power component 2 is installed on the right side of the bracket 1, the transverse cutting component 3 is installed on the front side of the bracket 1, and the longitudinal cutting component is installed on the rear of the bracket 1. Cutting components 4.

[0024] When it is necessary to use the device to cut tofu into strips, first place the tofu on the top of the support 1, then control the power component 2 to start working, and the power component 2 triggers the horizontal cutting component 3 to cut the tofu horizontally. After the tofu is cut horizontally, The bean curd is cut longitudinally by the longitudinal cutting assembly 4, and after the bean curd is cut, the power assembly 2 is controlled to stop working, and then the strip-cut tofu is removed.

[0025] The po...

Embodiment 2

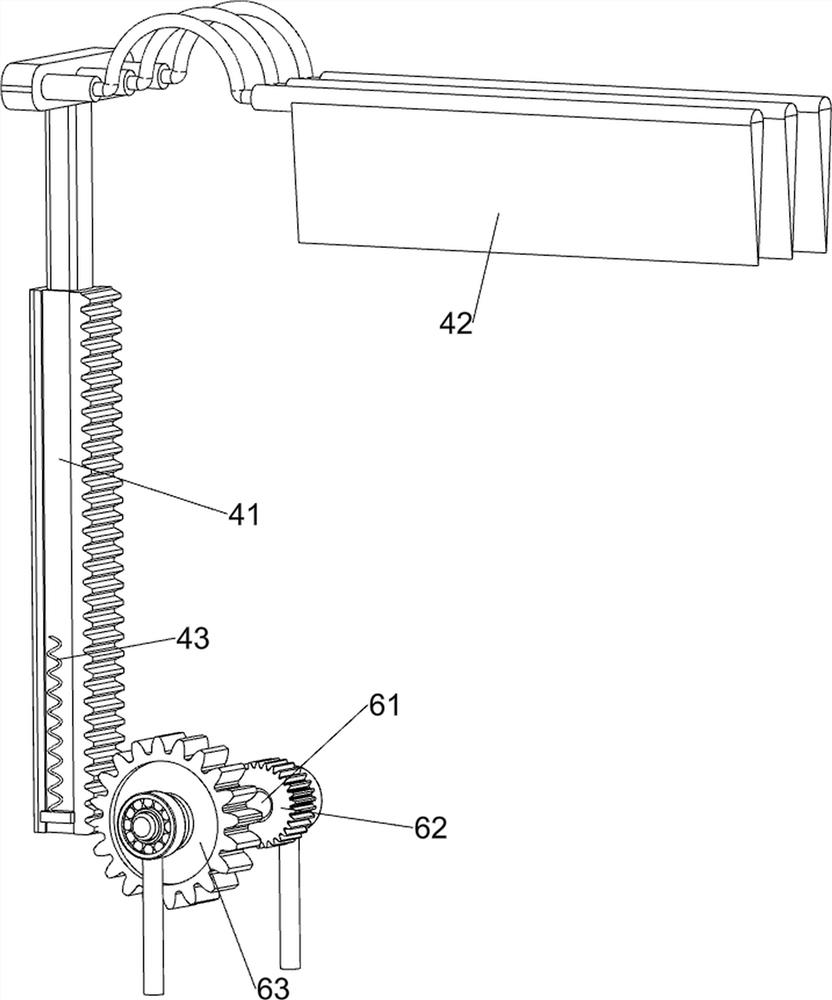

[0032] On the basis of Example 1, such as figure 1 , Figure 4 with Figure 5 As shown, a blanking assembly 5 is also included. The blanking assembly 5 is installed on the upper part of the bracket 1. The blanking assembly 5 includes a blanking plate 51, a guide sleeve 52, a stopper 53 and a second spring 54. The upper part of the bracket 1 is of a rotary type. A blanking plate 51 is provided, a guide sleeve 52 is fixedly connected to the inner top rear side of the bracket 1 by bolts, and a stopper 53 is slidably provided in the guide sleeve 52, and a second bracket is connected between the stopper 53 and the inner top rear side of the bracket 1 Spring 54.

[0033] After the bean curd is cut into strips, the block 53 is moved to the rear side, and the first spring 43 is compressed. When the block 53 leaves the bottom of the blanking plate 51, under the action of gravity, the blanking plate 51 swings downward to make the blanking The tofu on the plate 51 slides down, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com