Annular furnace for processing oil well pipe blank

A technology of annular furnace and oil well pipe, applied in the direction of furnace, furnace type, manufacturing tool, etc., can solve the problems of no rotation, structural damage, unable to maintain the shape of the tube blank to be processed well, and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

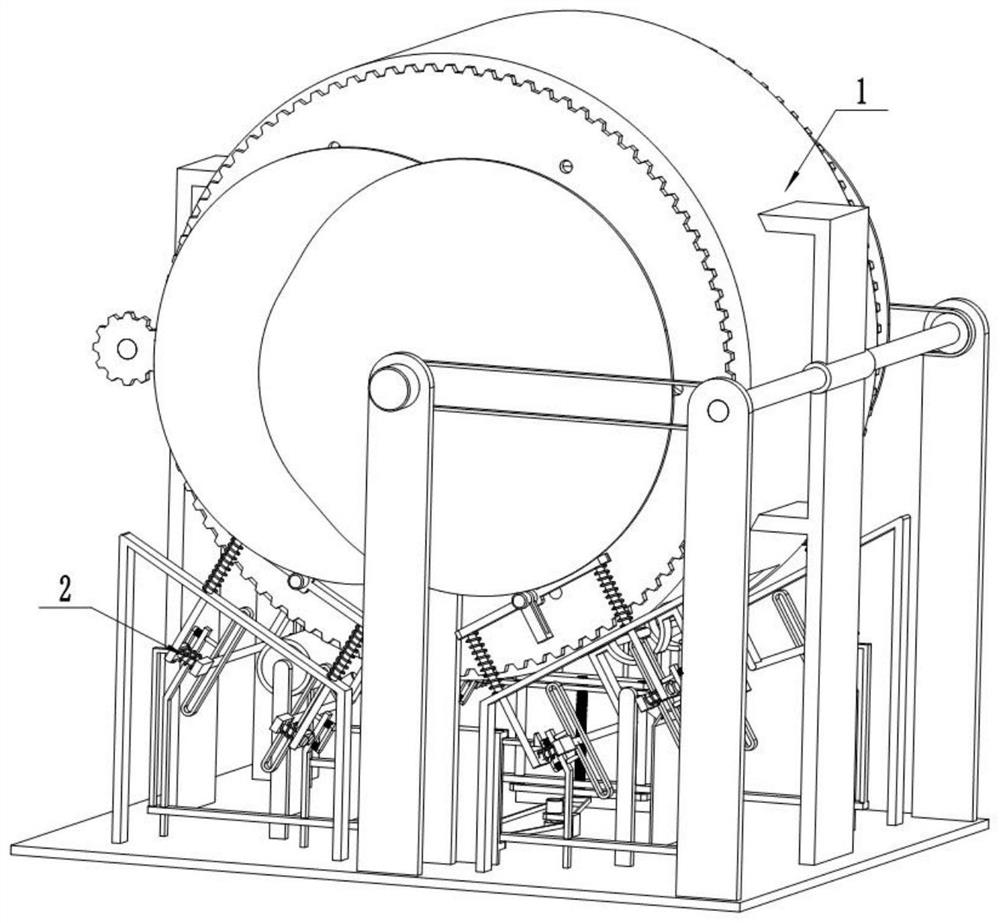

[0030] Example: Reference figure 1 The shown annular furnace for processing oil well tube blanks includes a heating assembly 1 for heating multiple tube blanks at the same time, and a replacement assembly 2 for automatically replacing the tube blanks is provided at the lower end of the heating assembly 1 .

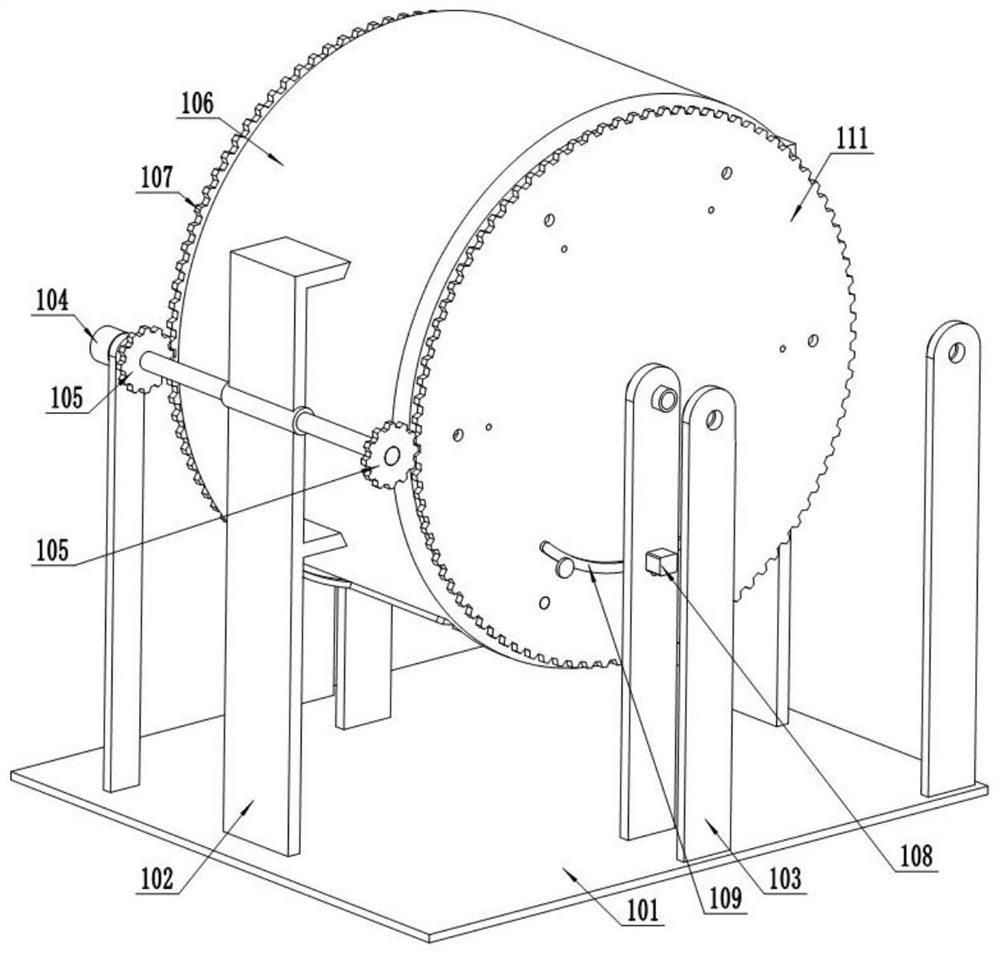

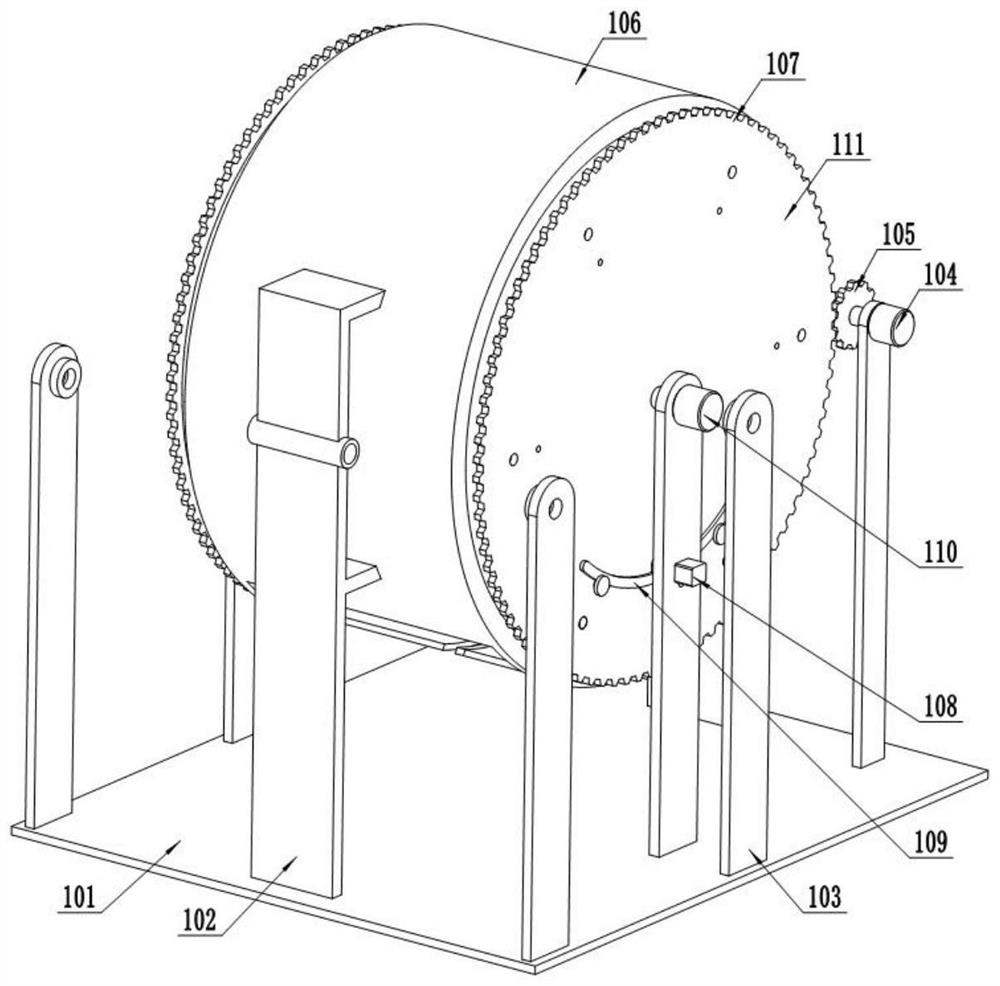

[0031] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6As shown, the heating assembly 1 includes a bottom plate 101, on which two sets of support plates 1 102 and six sets of support plates 2 103 are arranged, and a heating furnace 106 is arranged on the supporting plate 1 102, and a set of two supporting plates 106 are rotated on both sides of the heating furnace 106. The rotating disk 111 is provided with teeth 107 on the rotating disk 111 , the supporting plate 2 103 is provided with a driving motor 104 , and the output shaft of the driving motor 104 is provided with two sets of gears 105 , and the first two sets of gears 105 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com