Forming die for large hoop

A technology for forming molds and backing plates, which is used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of manual removal, low production efficiency, affecting production efficiency, etc., and achieves a reduction in overall width and improves production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

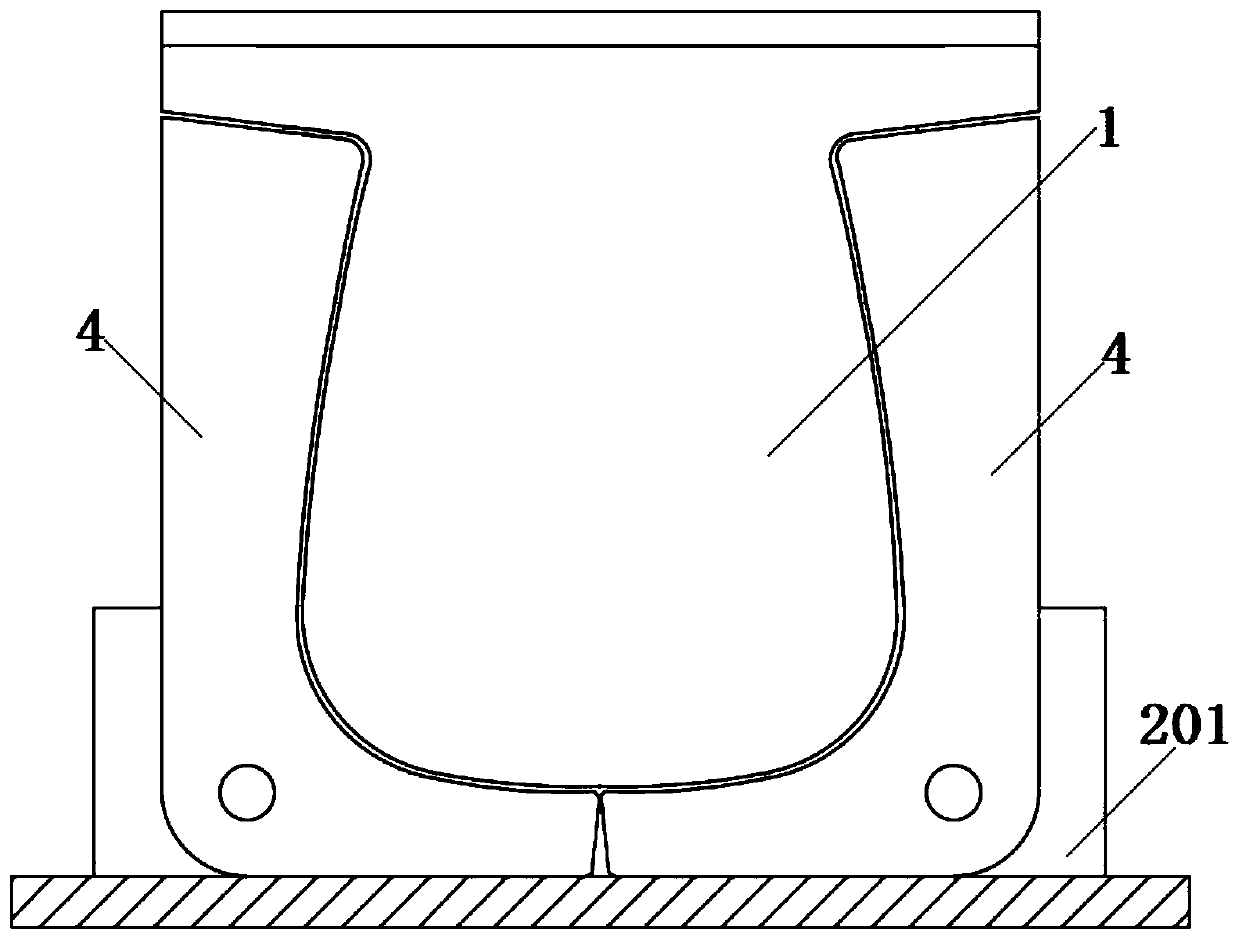

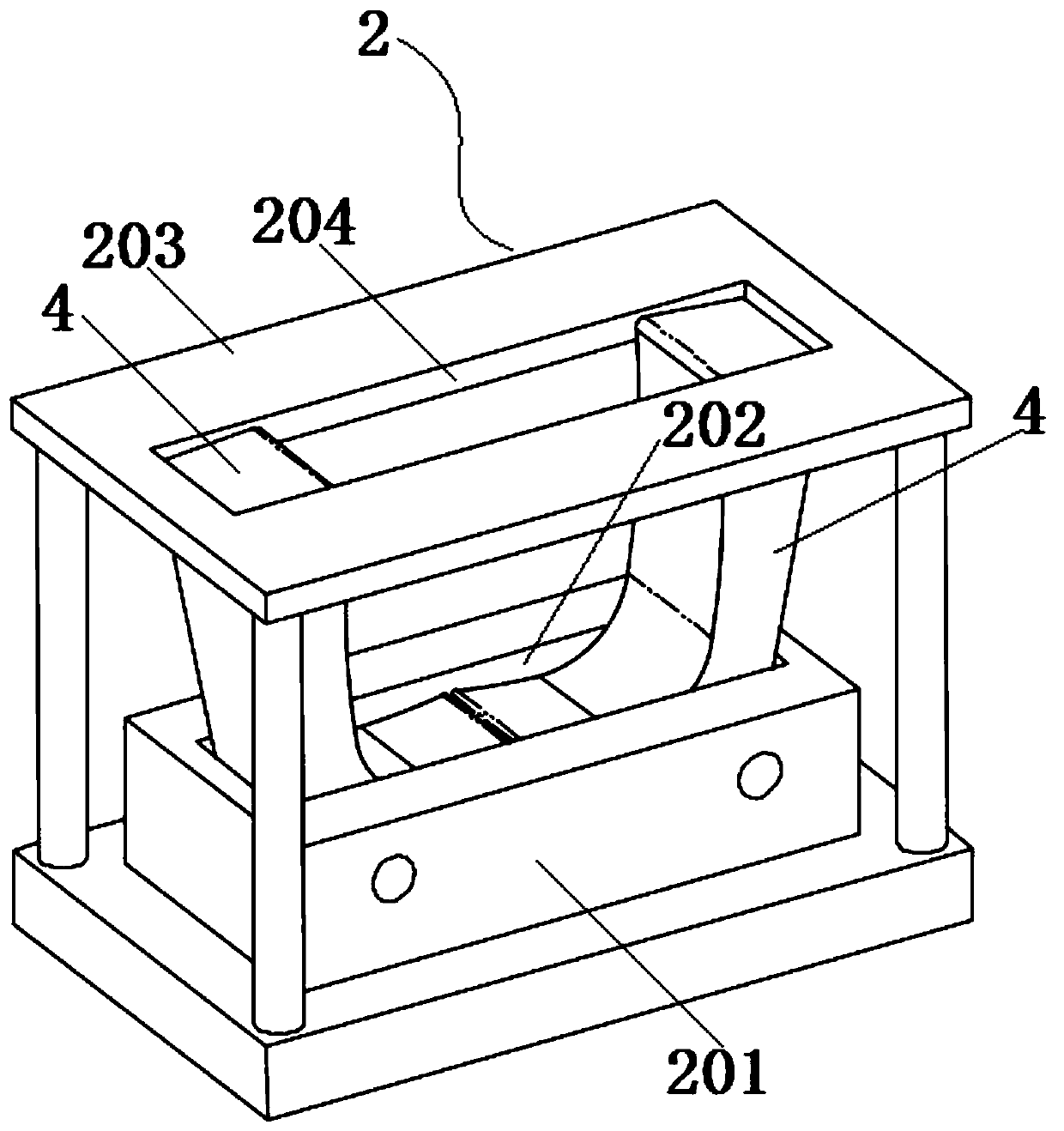

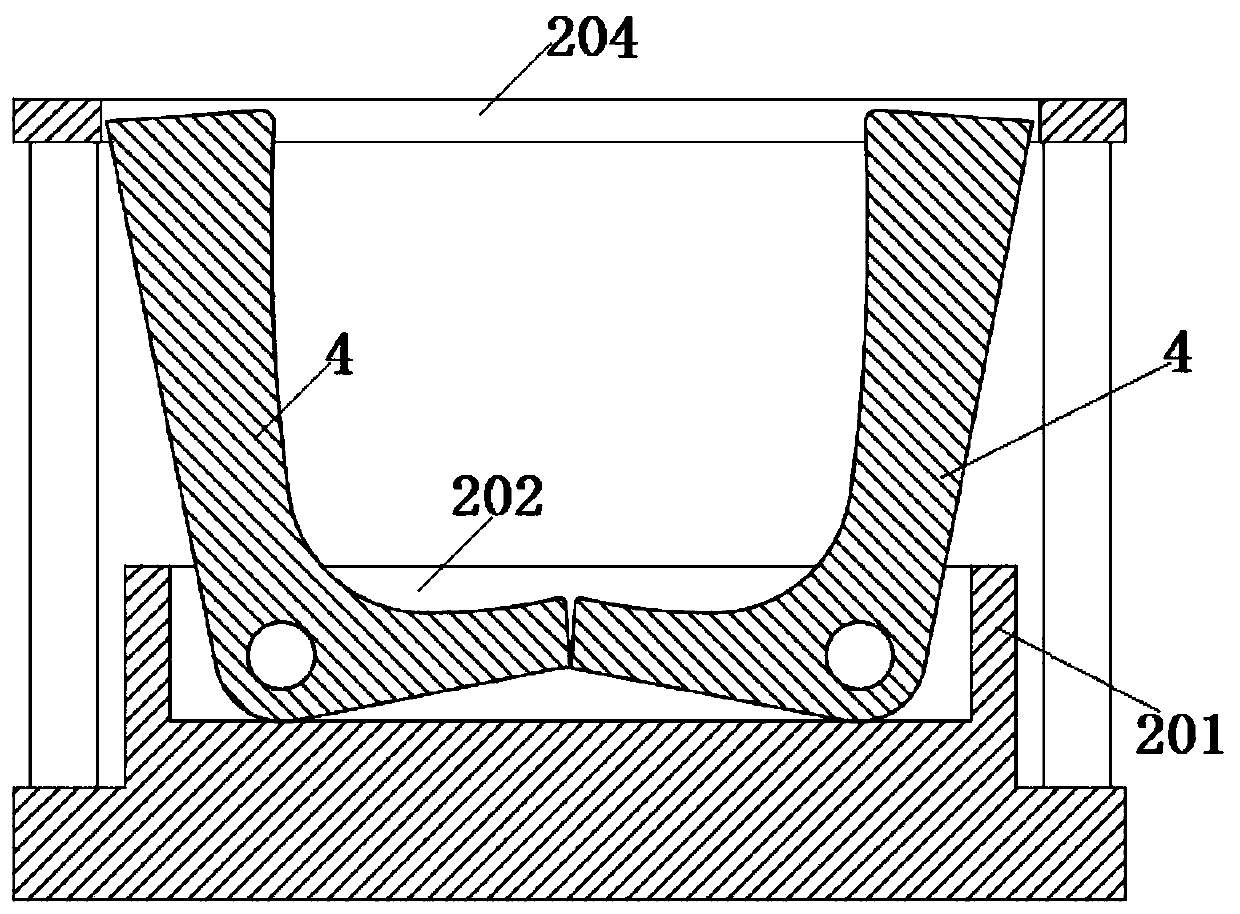

[0031] see figure 1 As shown, the present invention is a molding die for a large hoop, including an upper die 1 and a lower die 2; the cross-sectional shape of the upper die 1 in the vertical direction is U-shaped, and the width of the upper die 1 from top to bottom Gradually increase, so that the hoop after punching becomes a U-shaped structure, and the width of the hoop opening is smaller than the overall width of the hoop.

[0032] Such as Figure 5 As shown, the surface of the upper mold 1 is rounded, and the upper surface of the upper mold 1 is connected with an upper backing plate 11; the upper surface of the upper backing plate 11 is connected with a telescopic device 3.

[0033] Telescopic device 3 can be air cylinder or hydraulic cylinder, and telescopic device 3 can be provided with two, and two telescopic devices 3 are installed and fixed by mounting plate 301, offers through hole on mounting plate 301, and the telescopic end of telescopic device 3 passes through t...

Embodiment 2

[0042] Such as Figure 5-7 As shown, the upper mold 1 includes a wedge block 101; the wedge block 101 is an isosceles trapezoidal structure, and the lower surface of the wedge block 101 is a curved surface; the upper surface of the wedge block 101 is welded or threaded side by side with a pin shaft 104; the upper end of the pin shaft 104 runs through the upper The backing plate 11; the pin shaft 104 is set with a spring 105, and the lower end of the spring 105 abuts against the upper surface of the upper backing plate 11, and under the action of the spring 105, the upper surface of the wedge block 101 remains in a state of abutting against the lower surface of the upper backing plate 11 .

[0043]Side modules 102 are slidably connected to both sides of the wedge block 101;

[0044] The upper end of the side module 102 is welded with a bending block 103, and the side module 102 and the bending block 103 can also be an integral structure; Dovetail slots or T-shaped slots are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com