Automobile seat

A technology for car seats and seat backs, which is applied to vehicle seats, seat heating/ventilation devices, vehicle components, etc. It can solve the problems that the fan cannot be directly fixed on the plate frame, the investment cost is large, and it is not a solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

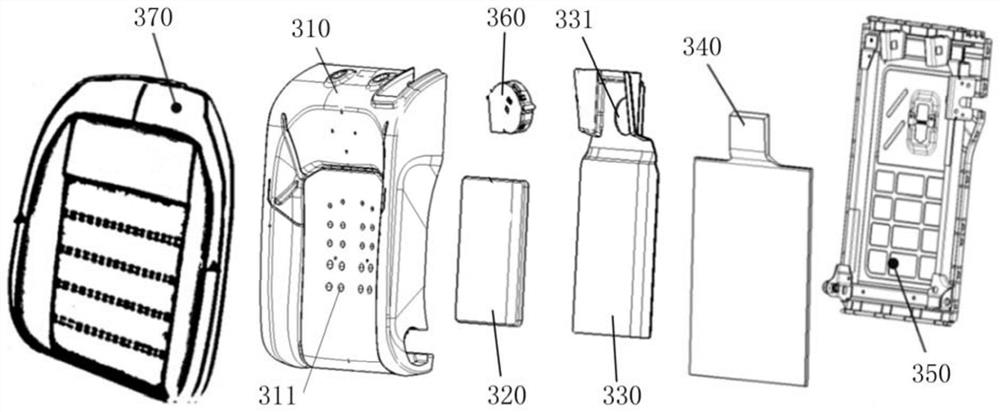

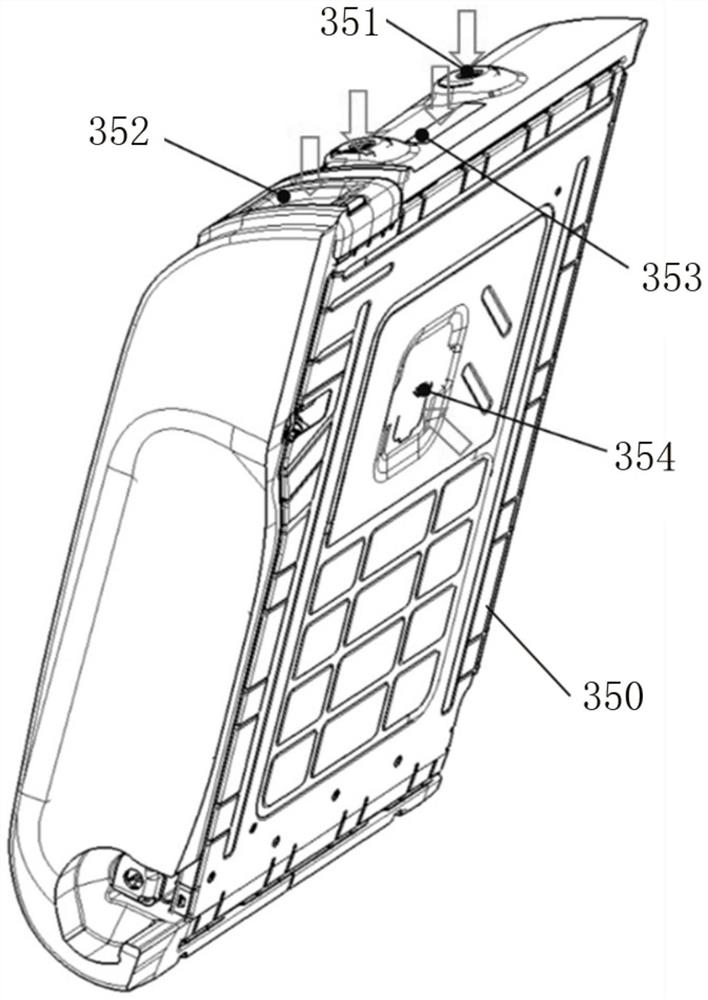

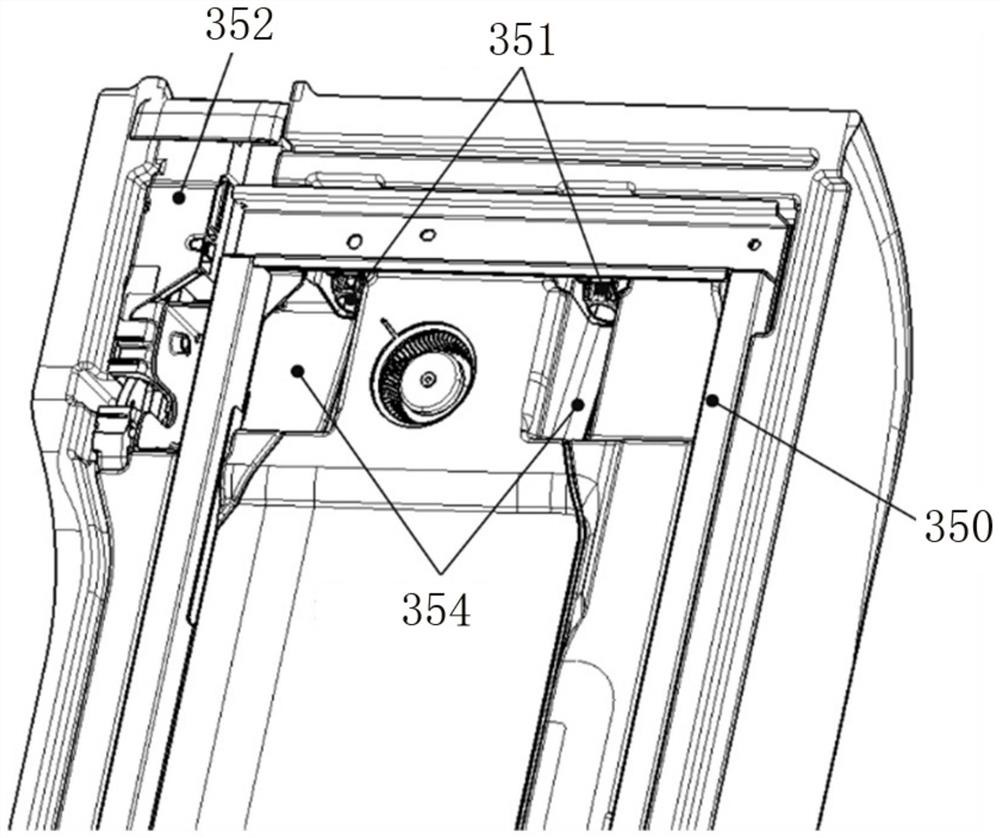

[0057] like figure 1 As shown, the present embodiment provides a car seat, the seat back includes sequentially from front to back in the thickness direction: a face cover 370, a foam body 310, an inner 3D-mesh 320, a gasket 330 and a backrest frame 350;

[0058] A sealed cavity is enclosed between the foam body 310 and the gasket 330, and the inner 3D-mesh 320 is filled in the sealed cavity to maintain the air in the sealed cavity (even when the seat is seated and the backrest is squeezed). The air outlet 311 is arranged on the front side (passenger side) of the foam body 310 to communicate with the inside and outside of the sealed chamber; the face cover 370 covers the foam body 310 In addition, an air passage hole is provided at a corresponding position of the air outlet hole 311 . The sealing gasket 330 is provided with a via hole 331 , and a fan 360 is provided at the via hole 331 for blowing air into the sealed cavity and then blowing out through the air outlet hole 311 ...

Embodiment 2

[0071] This embodiment is basically the same as Embodiment 1, except that the car seat in this embodiment also includes a headrest. like Image 6 As shown, the headrest includes: a base module 10 (body), and a wing portion 20 arranged on the base module 10, and a speaker 30 is arranged on the wing portion 20; the wing portion 20 is divided into a left wing portion 21 and a right wing portion 20. The wings 22; the left wing 21 and the right wing 22 are respectively provided with a speaker 30. On a projection plane perpendicular to the front-rear direction of the vehicle body, the left wing portion 21 and the right wing portion 22 are respectively arranged on the left and right sides of the driver's or passenger's head. In the present application, the front side of the headrest is the side on which the passenger or driver sits, and the left and right hands of the passenger or driver correspond to the left and right sides of the headrest, respectively.

[0072] In this applicat...

Embodiment 3

[0087] This embodiment is basically the same as Embodiment 1, except that:

[0088] like Figure 14 As shown, an audio headrest for a car seat disclosed in this embodiment is provided with an execution module 100 for maintaining and changing the swing angle of the wings.

[0089] The execution module 100 in this embodiment is arranged on the base module 10 ; or, there is an installation space on the base module 10 , and the execution module 100 is arranged on the middle fixing plate 50 .

[0090] The execution module 100 includes: a cylindrical body 110 , a first push rod 120 , a second push rod 130 and a rack and pinion transmission pair 140 . The cylindrical body 110 is generally disposed along the front and rear directions of the vehicle body. The top ends of the first push rod 120 and the second push rod 130 are inserted into the cylindrical body 110 from the front and rear ends respectively. The middle through hole of the body 110 slides.

[0091] The rack-and-pinion t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com