Coolant valve for a vehicle

A coolant valve and coolant technology, which is used in engine cooling, coolant flow control, valve devices, etc., and can solve the problems of high bearing capacity, low driving torque of valve elements, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

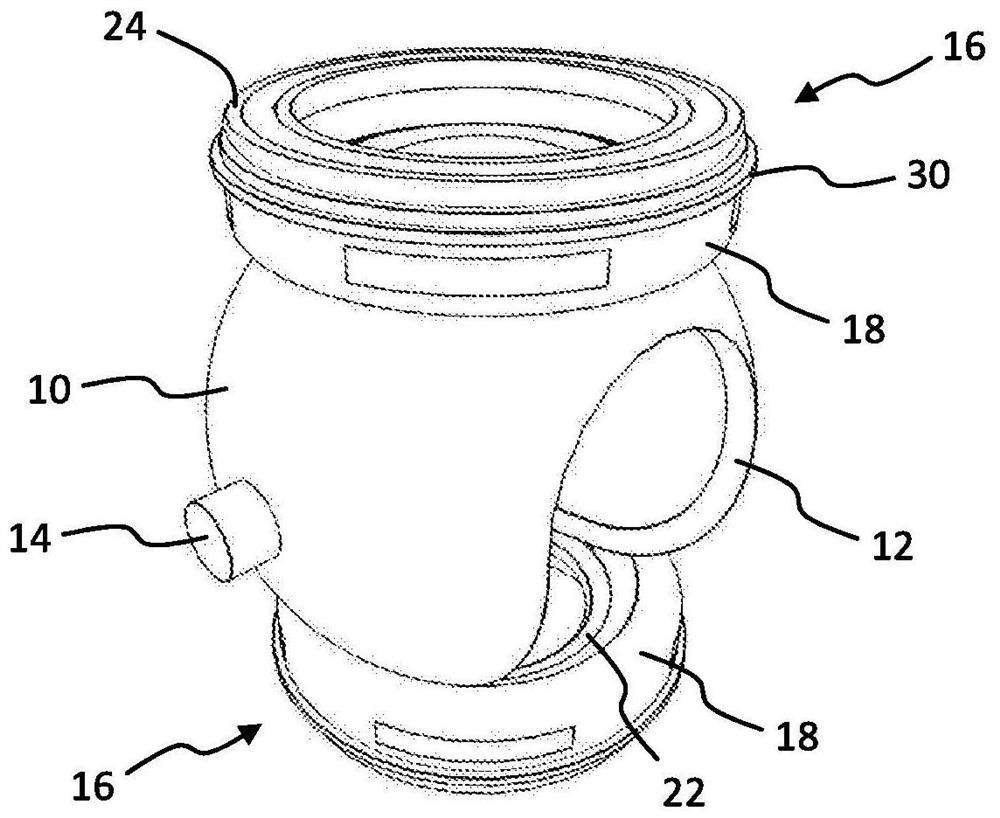

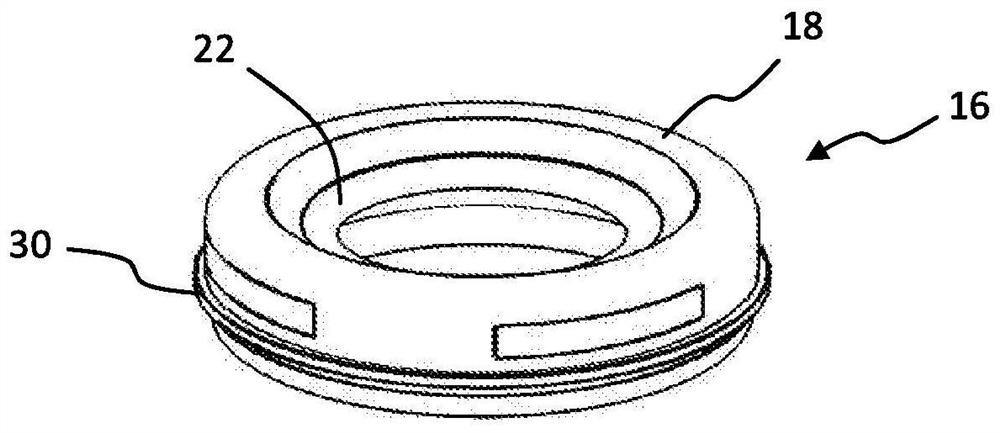

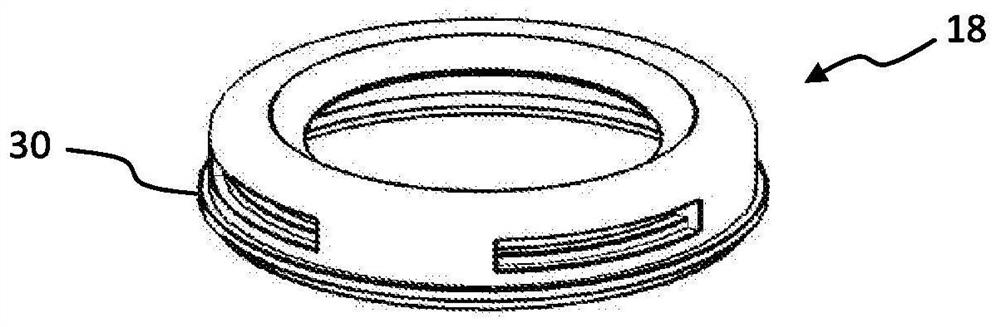

[0046] figure 1 The coolant valve shown has a valve element 10 , in the example shown a spherical valve element 10 . In the example shown, the valve element has an orifice 12 and bearing journals 14, which are arranged on opposite sides and at the figure 1 Only one bearing journal can be seen in . The valve element 10 is pivotably mounted in the housing via a bearing journal 14 (for illustration reasons in figure 1 not shown in more detail). The valve element can be pivoted, for example, by an electric drive which is controlled by a control device. figure 1 The coolant valve shown is installed in the cooling circuit of a vehicle such as a car or truck with an internal combustion engine and / or an electric motor. The housing has for example three coolant ports, it is possible, for example, that the coolant port connected to the coolant inlet is connected by pivoting of the valve element 10 to the first coolant port or the second of the two further coolant ports. Coolant por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com