A floor tile gap cleaning device

A technology for cleaning devices and gaps, used in carpet cleaning, floor cleaning, cleaning machinery, etc., can solve the problems of slow cleaning speed, troublesome operation, loud noise, etc., and achieve the effect of ensuring the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

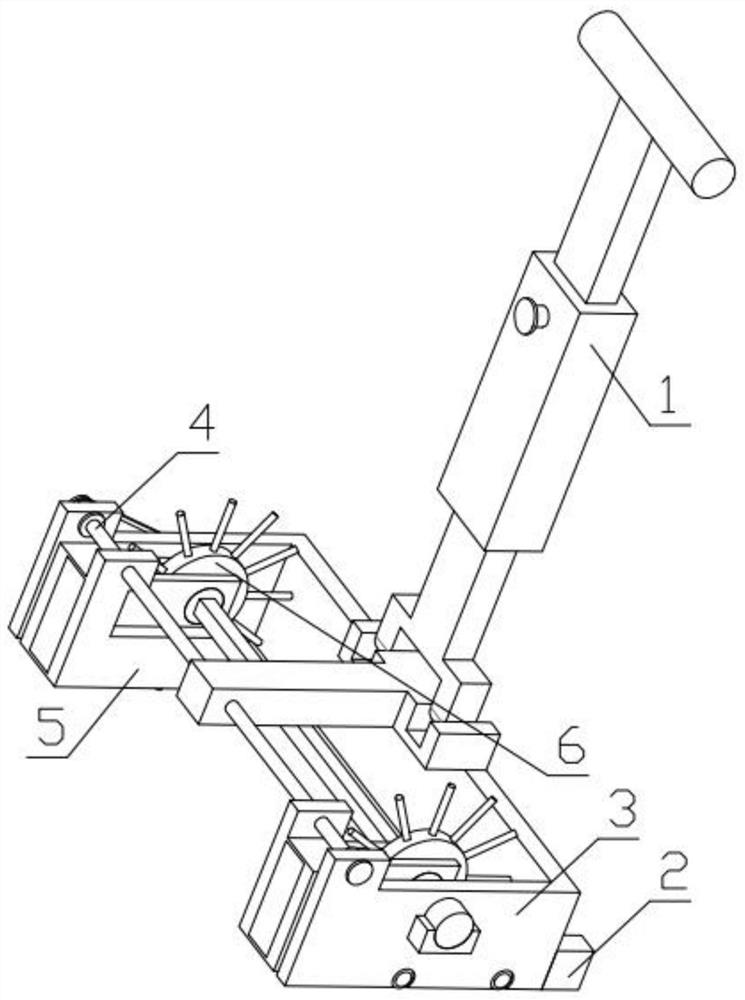

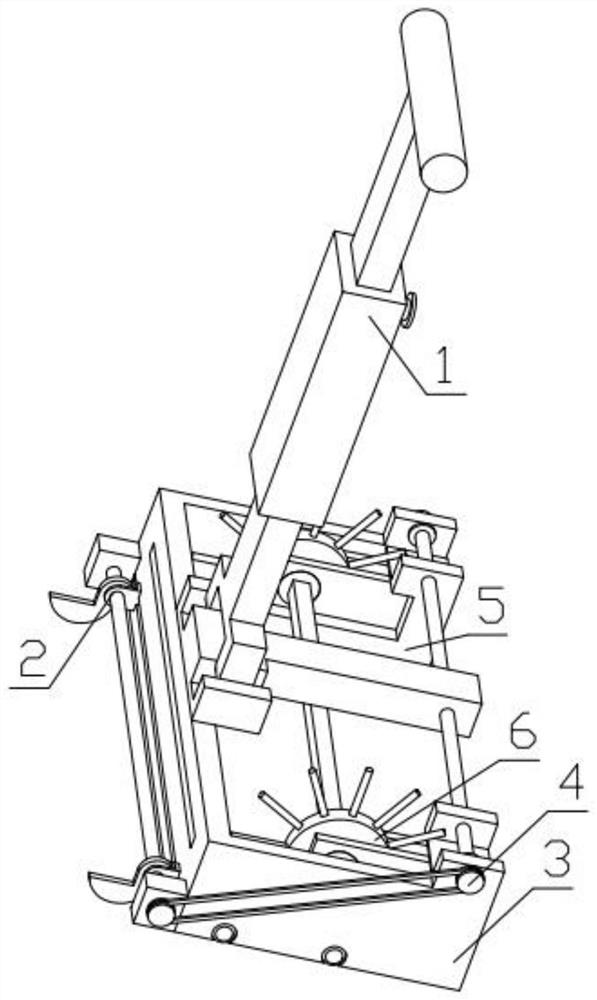

[0036] Combine below Figure 1-16 Describe this embodiment, a floor tile gap cleaning device, including a telescopic handle 1, a limit mechanism 2, a U-shaped frame 3, a synchronous adjustment mechanism 4, a collection box 5 and a cleaning mechanism 6, and the limit mechanism 2 is fixedly installed On the U-shaped frame 3, the U-shaped frame 3 is hinged with the telescopic handle 1, the synchronous adjustment mechanism 4 is engaged with the limit mechanism 2, the synchronous adjustment mechanism 4 is rotatably installed on the U-shaped frame 3, and the cleaning mechanism 6 is fixedly installed on the U-shaped frame 3 On the shaped frame 3, the collection box body 5 is rotatably installed on the cleaning mechanism 6, and the synchronous adjustment mechanism 4 is threadedly connected with the collection box body 5.

specific Embodiment approach 2

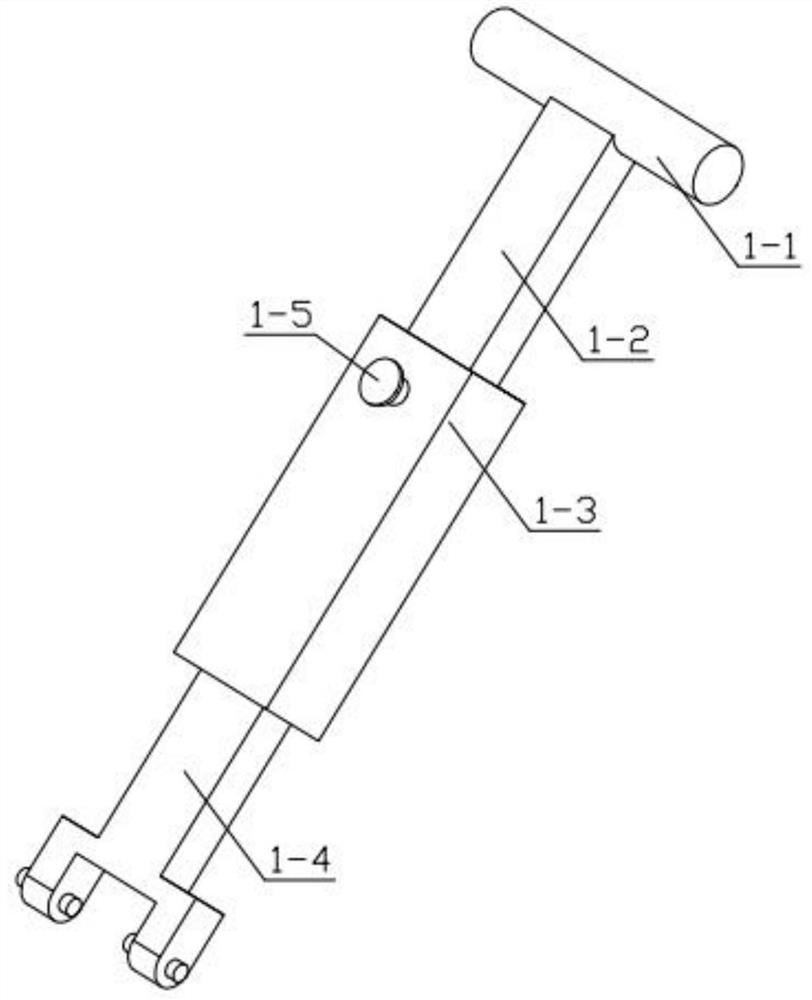

[0037] Combine below Figure 1-16Describe this embodiment, this embodiment will further explain the first embodiment, the telescopic handle 1 includes an armrest 1-1, a telescopic rod 1-2, a telescopic tube 1-3, a hinge 1-4, and a positioning screw 1-5 , the armrest 1-1 is fixedly installed on one end of the telescopic rod 1-2, and the other end of the telescopic rod 1-2 is slidably installed in the groove provided on the telescopic tube 1-3, and the positioning screw 1-5 passes through the telescopic tube 1- 3 is threadedly connected with the handrail 1-1, and the telescopic tube 1-3 is fixedly equipped with a hinge 1-4, and the hinge 1-4 is hinged with the U-shaped frame 3.

specific Embodiment approach 3

[0038] Combine below Figure 1-16 Describe this embodiment, and this embodiment will further explain Embodiment 1. The limit mechanism 2 includes a fixed head 2-1, a two-way threaded rod 2-2, a fixed head 2-3, and a top sprocket 2- 4. Limit slider 2-5, limit plate 2-6, one end of the two-way threaded rod 2-2 is installed in the groove provided on the fixed head 2-1, and the two-way threaded rod 2-2 The other end is rotatably installed in the groove provided on the fixed head two 2-3, the top sprocket 2-4 is fixedly installed on the two-way threaded rod one 2-2, and the limit slide 2-5 is connected with the two-way threaded rod one 2-2. 2 threaded connection, the limit plate 2-6 is rotatably installed on the limit slider 2-5, the fixed head 2-1 and the fixed head 2 2-3 are fixedly installed on the U-shaped frame 3, the limit slide 2 -5 is slidably mounted on the U-shaped frame 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com