Self-cleaning device for mountainous area curve spherical mirror

A spherical mirror and self-cleaning technology, applied in the field of spherical mirrors, can solve the problems of high time cost, ineffective function, high wiring cost, and achieve the effect of increasing evaporation and increasing cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

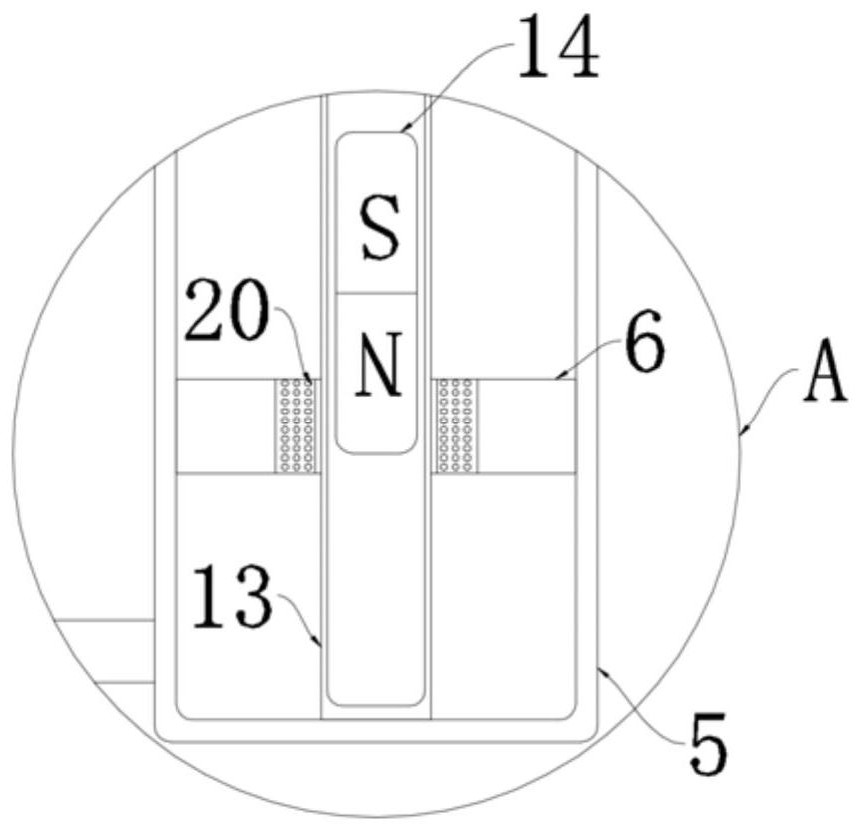

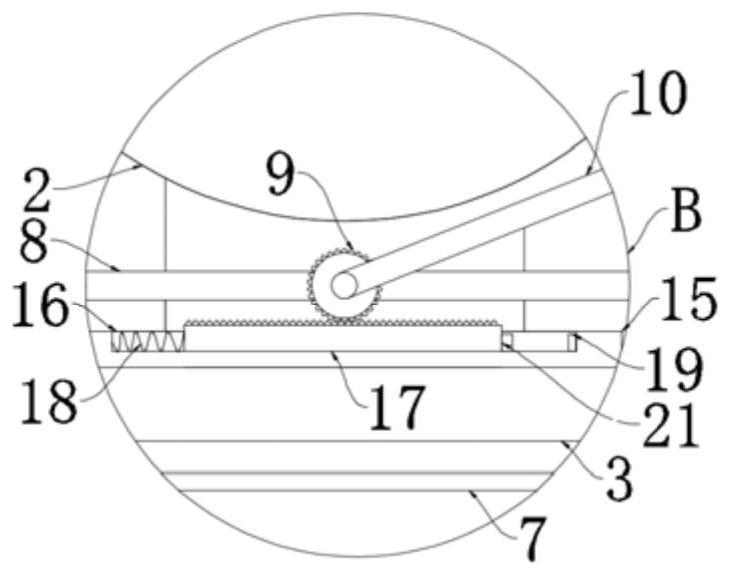

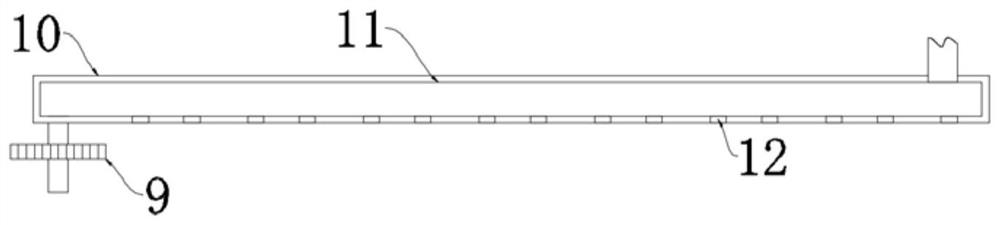

[0037] refer to Figure 1-4 , a self-cleaning device for a curved spherical mirror in mountainous areas, comprising a support column 1 fixed on the ground and a spherical mirror body 2 fixed on the support column 1, and an installation box 3 is fixedly connected to the side wall of the support column 1;

[0038] The wall of the installation box 3 is provided with a liquid storage cavity, and the bottom of the liquid storage cavity is fixedly connected with a heat conduction plate 25 that runs through the installation box 3. The low boiling point evaporating liquid 4 is housed in the liquid storage cavity. 4. Realize that when the sun shines on the heat conduction plate 25, the temperature of the heat conduction plate 25 rises, so that the low boiling point evaporating liquid 4 reaches the evaporation temperature, thereby providing steam as the power of the whole device;

[0039] Two installation cylinders 5 are fixedly connected in the installation box 3, and slide plugs 6 are...

Embodiment 2

[0053] refer to Figure 5-6 The difference between this embodiment and Embodiment 1 is that liquid storage tanks 22 are arranged on both sides of the liquid storage chamber, and concentrated nitric acid is filled in the two liquid storage tanks 22;

[0054] The side walls of the two liquid storage tanks 22 are provided with heat conduction rods 23 connected to the heat conduction plates 25;

[0055] Two concave mirrors 24 are arranged on the installation box 3 , and the focal points of the two concave mirrors 24 are all concentrated on the heat conducting plate 25 .

[0056] The filling volume of the concentrated nitric acid is three-quarters of the liquid storage tank 22, and the two liquid storage tanks 22 are made of transparent glass. By setting the concentrated nitric acid, when the heat is insufficient, the concentrated nitric acid reacts to release heat, so that the low Boiling point evaporating liquid 4.

[0057] The working principle of this embodiment is that in wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com