Plastic mold detection and maintenance device

A technology of plastic molds and detection sleeves, applied in the field of plastic molds, can solve the problems of mold falling, forgetting to apply lubricating oil regularly, and hole blockage, etc., to achieve the effect of ensuring use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

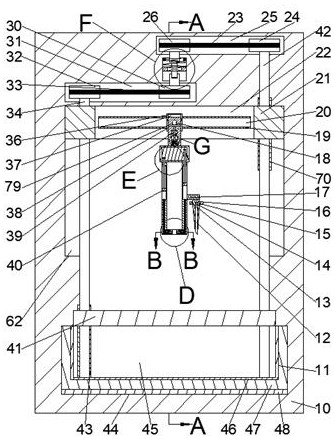

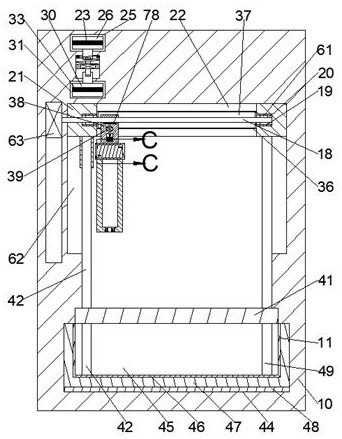

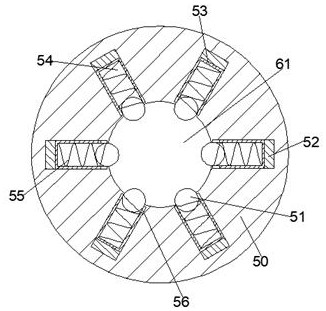

[0019] Combine below Figure 1-8 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0020] A plastic mold inspection and maintenance device according to the present invention includes a box body 10, the lower end of the box body 10 is provided with a rust removal chamber 44, and the lower wall of the rust removal chamber 44 is fixed with an ultrasonic plate 48, and the ultrasonic wave An ionization box 47 is fixed on the upper end of the plate 48, and an insulating cavity 11 with an opening facing upward is arranged in the ionization box 47, and an insulating box 46 is fixed on the lower wall of the insulating cavity 11, and an opening is arranged in the insulating box 46. The upward ionization chamber 45 is provided with a supporting plate 41 sliding up and down in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com