A device for tire pressure monitoring

A tire pressure monitoring and detection device technology, which is applied in the field of auto parts, can solve the problems of troublesome replacement, damage to the pressure detection device, and high replacement cost, and achieve the effects of easy replacement, easy disassembly, and increased sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

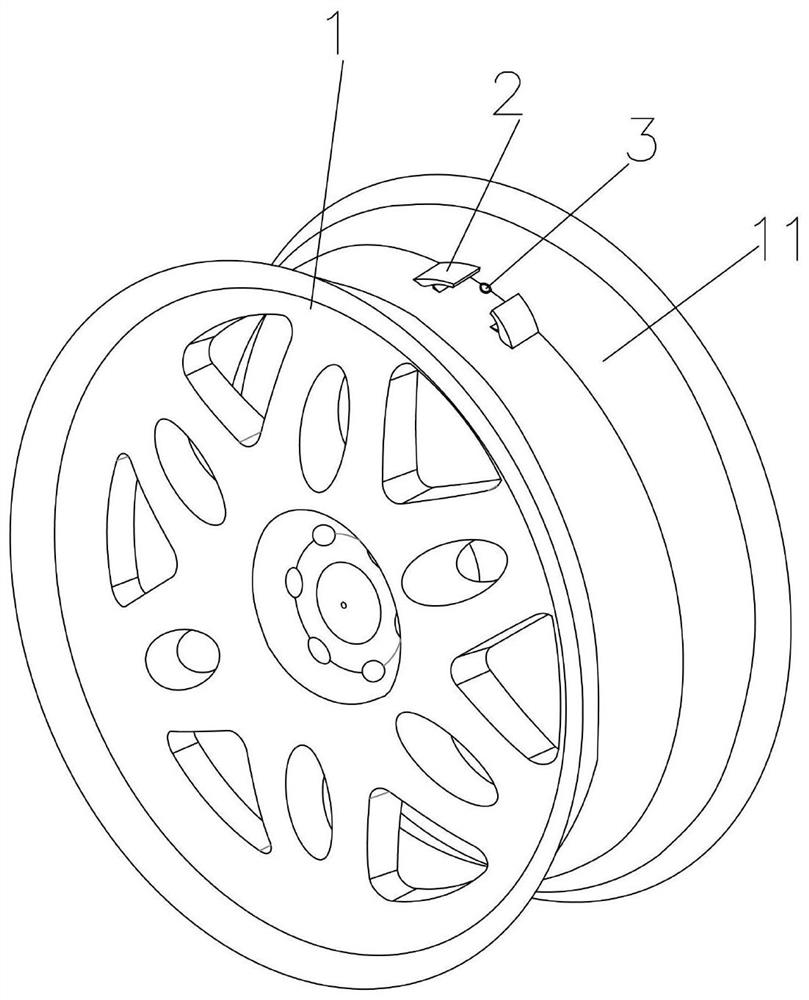

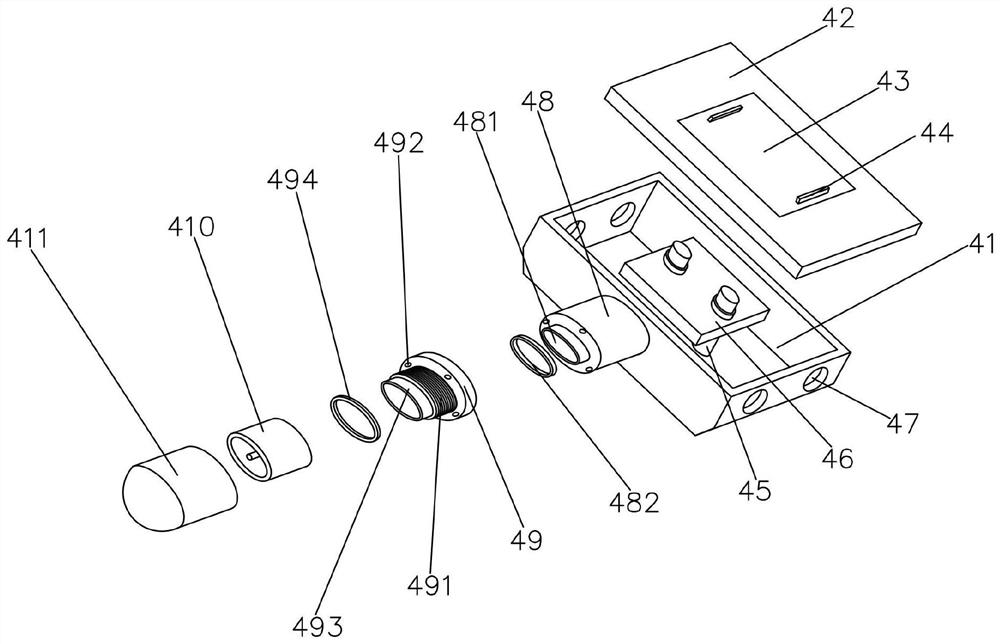

[0015] Example: A device for tire pressure monitoring, such as Figure 1-Figure 3 As shown, it includes a tire hub 1, a limiting device 2 and a detection device, and is characterized in that: the surface of the tire hub 1 is provided with an inner ring 11, and the surface of the inner ring 11 is provided with a through hole 3, and the through hole 3 is oblique to the tire hub. 1 is arranged through the inner side, the limit device 2 is arranged on both sides of the through hole 3, one end of the detection device is inserted into the inside of the limit device 2, and the other end of the detection device extends to the outside of the tire hub 1 through the through hole 3.

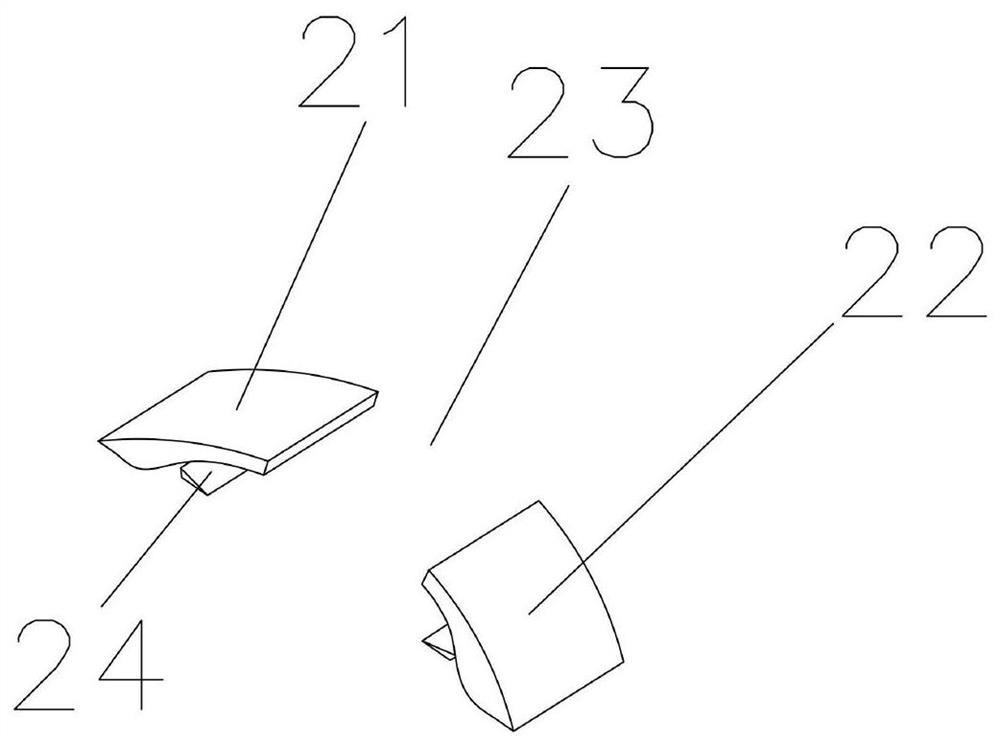

[0016] The limiting device 2 includes a left clamping block 21 and a right clamping block 22 fixedly arranged on the inner ring 11 , the left clamping block 21 and the right clamping block 22 are arranged opposite to each other, and the left clamping block 21 An installation gap 23 is formed between the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com