Anti-fog deicing automobile windshield

A technology for windshields and automobiles, applied to windshields, vehicle maintenance, vehicle parts, etc., can solve problems such as the inability to use resistance wires, long action time, and melting of frost, so as to improve the heat preservation effect, defogging and deicing speed Fast, the effect of improving the speed of melting ice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

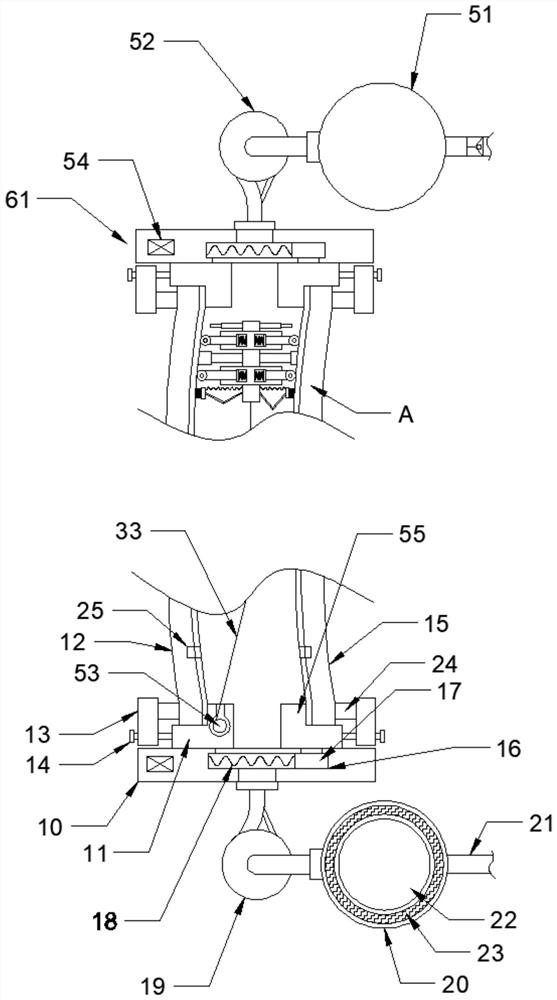

Embodiment 1

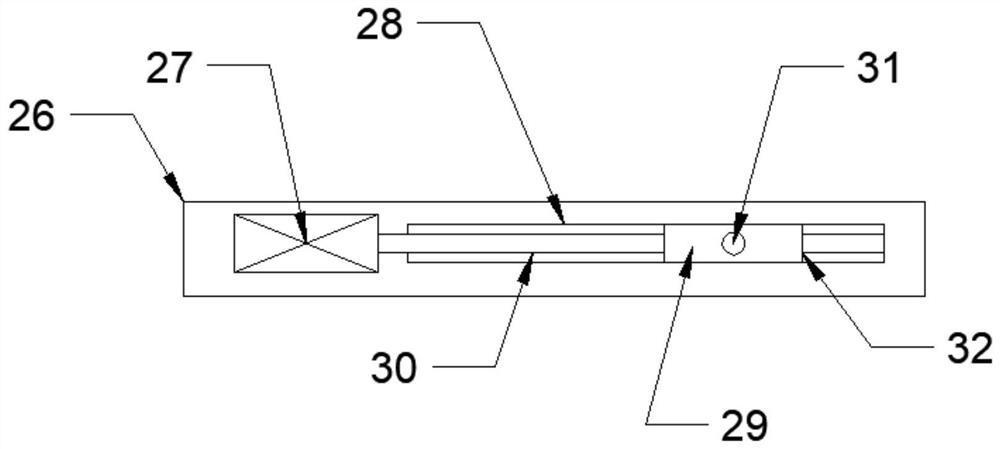

[0031]Preferably, Embodiment 1: the gap control device 61 includes a control body 26, the control body 26 is provided with a control chute 28, and the control chute 28 is slidably provided with a control slider 29, and the control slider 29 The middle is provided with threaded hole 32, and described control chute 28 wall bodies are rotated to be provided with threaded rod 30, and described threaded hole 32 is threadedly connected with described threaded rod 30, and described control chute 28 wall body is provided with control motor 27, so The shaft of the control motor 27 is fixedly connected to the threaded rod 30 , the front side of the control slider 29 is fixedly provided with a connecting rod 31 , and the connecting rod 31 is fixedly connected to the rear seat 55 .

Embodiment 2

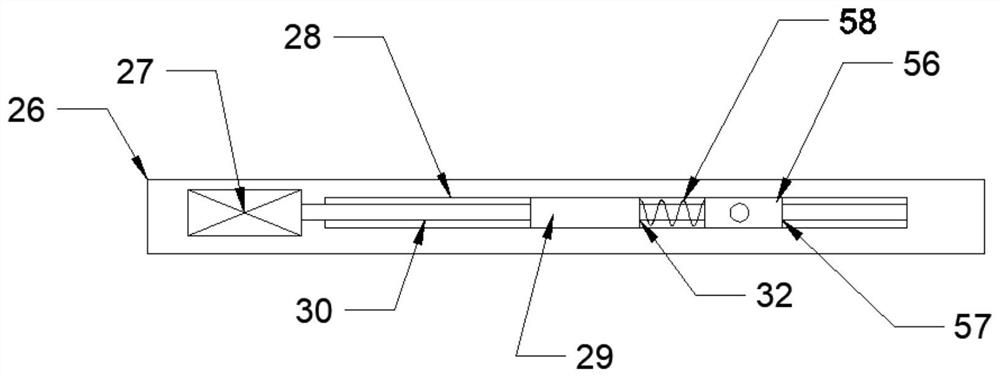

[0032] Embodiment 2: the gap control device 61 includes a control body 26, the control body 26 is provided with a control chute 28, and the control chute 28 is slidably provided with a control slider 29, and the middle of the control slider 29 is provided with Threaded hole 32, the wall of the control chute 28 is rotated and provided with a threaded rod 30, the threaded hole 32 is threadedly connected to the threaded rod 30, the wall of the control chute 28 is provided with a control motor 27, and the control motor The shaft of 27 is fixedly connected with the threaded rod 30, the control chute 28 is slidably provided with a control block 56, the middle of the control block 56 is provided with a through hole 57, and the through hole 57 passes through the threaded rod 30, so A pressure spring 58 is provided between the control block 56 and the control slider 29 , and a connecting rod 31 is fixedly arranged on the front side of the control block 56 , and the connecting rod 31 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com