Intelligent carrying robot and using method thereof

A technology of intelligent handling and robots, applied in the direction of lifting devices, etc., can solve problems such as inability to transport items, single function, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

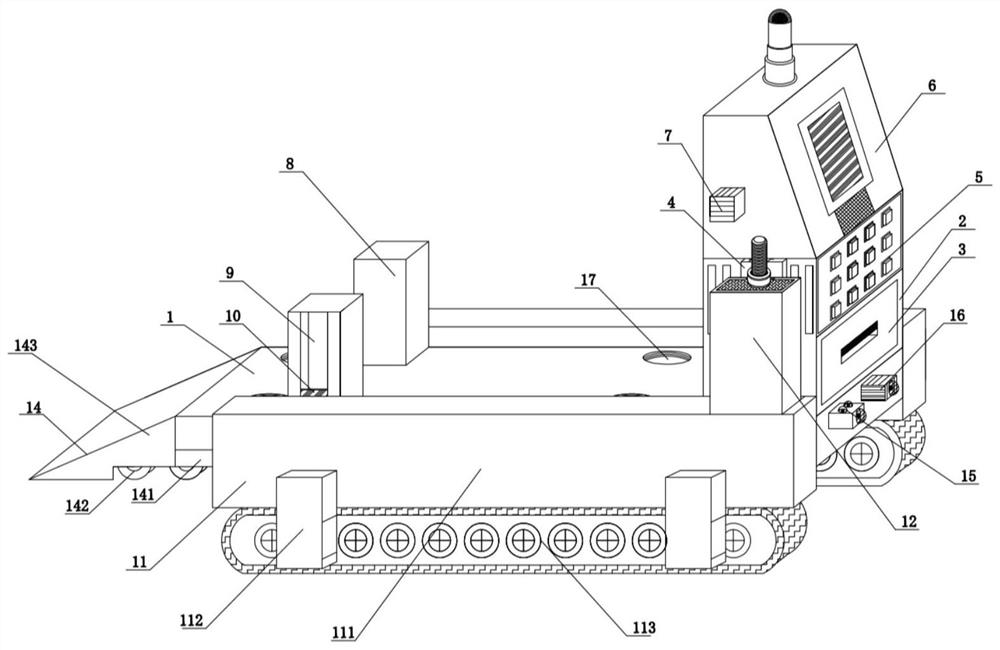

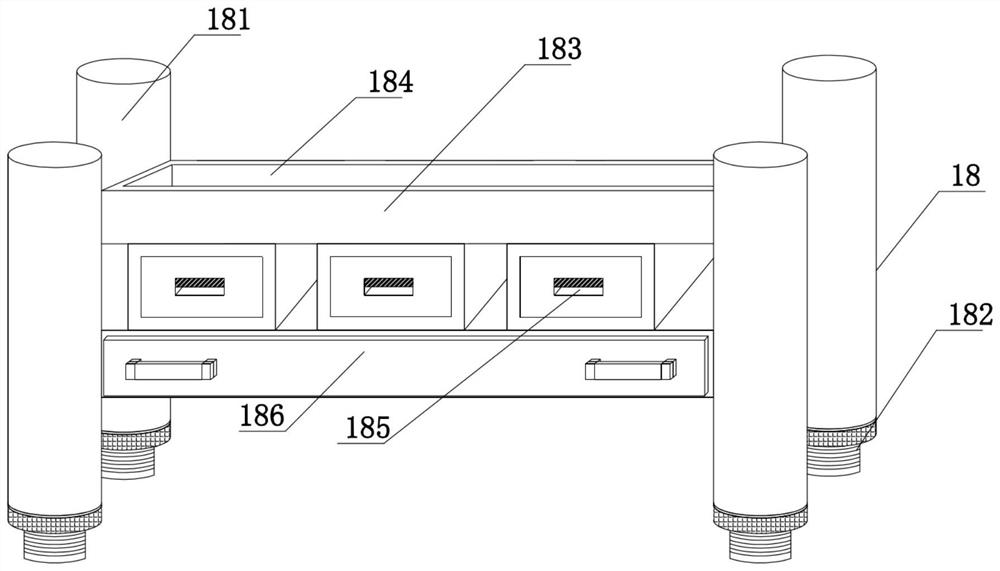

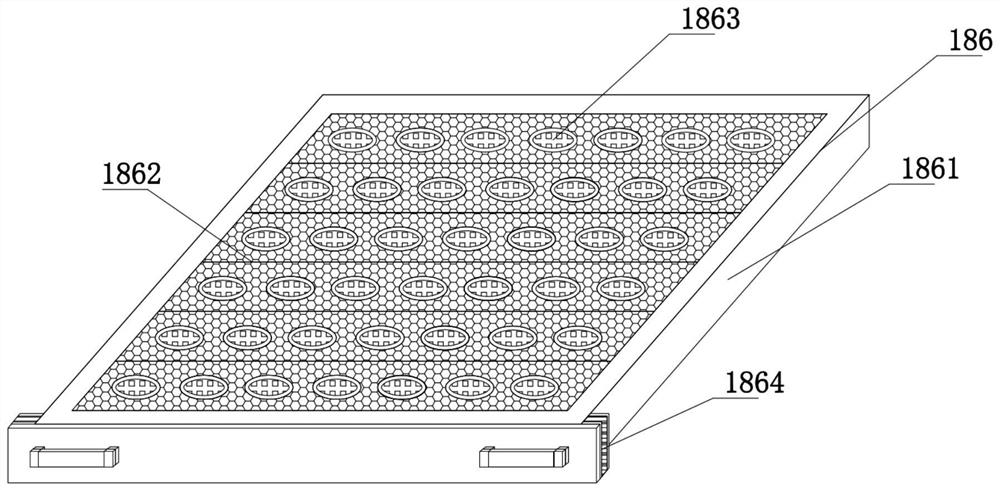

[0034] see Figure 1-6 , an intelligent handling robot, comprising a transportation platform 1, a tool box 2 is fixedly installed on the right side of the transportation platform 1, a tool box 3 is inserted inside the tool box 2, and the tool box 3 is fixedly installed in the middle of the front and rear sides There is a guide rail 4, a PLC controller 5 is fixedly installed on the top of the toolbox 2, an energy storage device 6 is fixedly installed on the top of the PLC controller 5, and an infrared sensor 7 is fixedly installed in the middle of the front and back of the energy storage device 6 , the front and rear ends on the left side of the top of the transport table 1 are fixedly equipped with a fixed block 8, and a chute 9 is provided inside the fixed block 8, and a first slider 10 is slidably connected in the chute 9, and the first slider 10 is slidably connected to the first slider 10. The outside of the slider 10 is fixedly equipped with a driving device 11, the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com