Self-propelled concrete curing device for water conservancy construction

A concrete and self-propelled technology, applied in spraying devices, spraying devices with movable outlets, infrastructure engineering, etc., can solve the problems of limited spraying range and low efficiency of maintenance operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

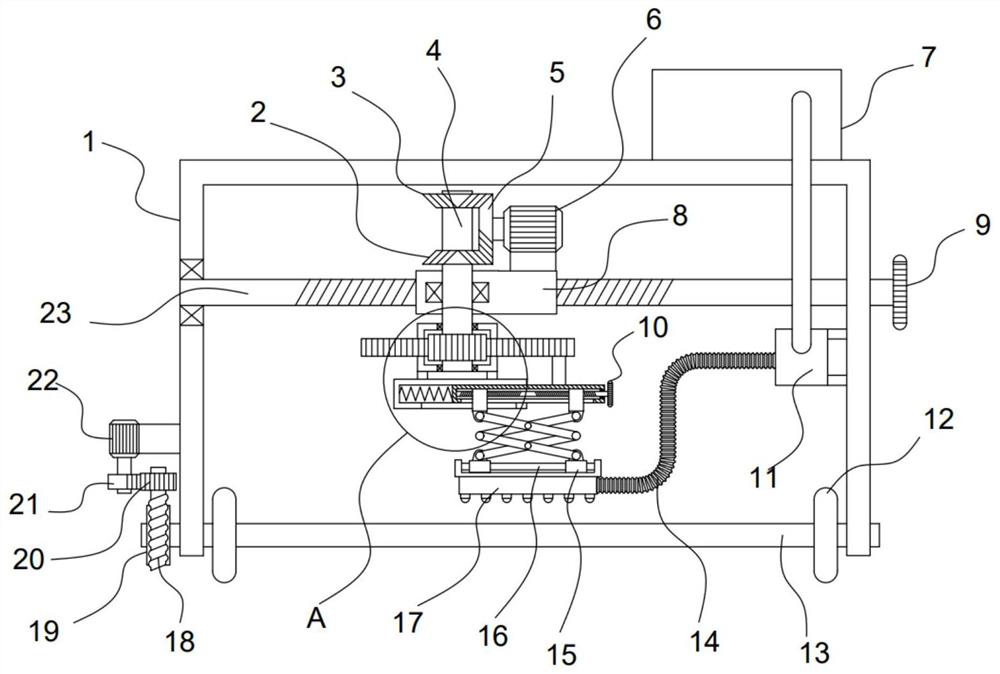

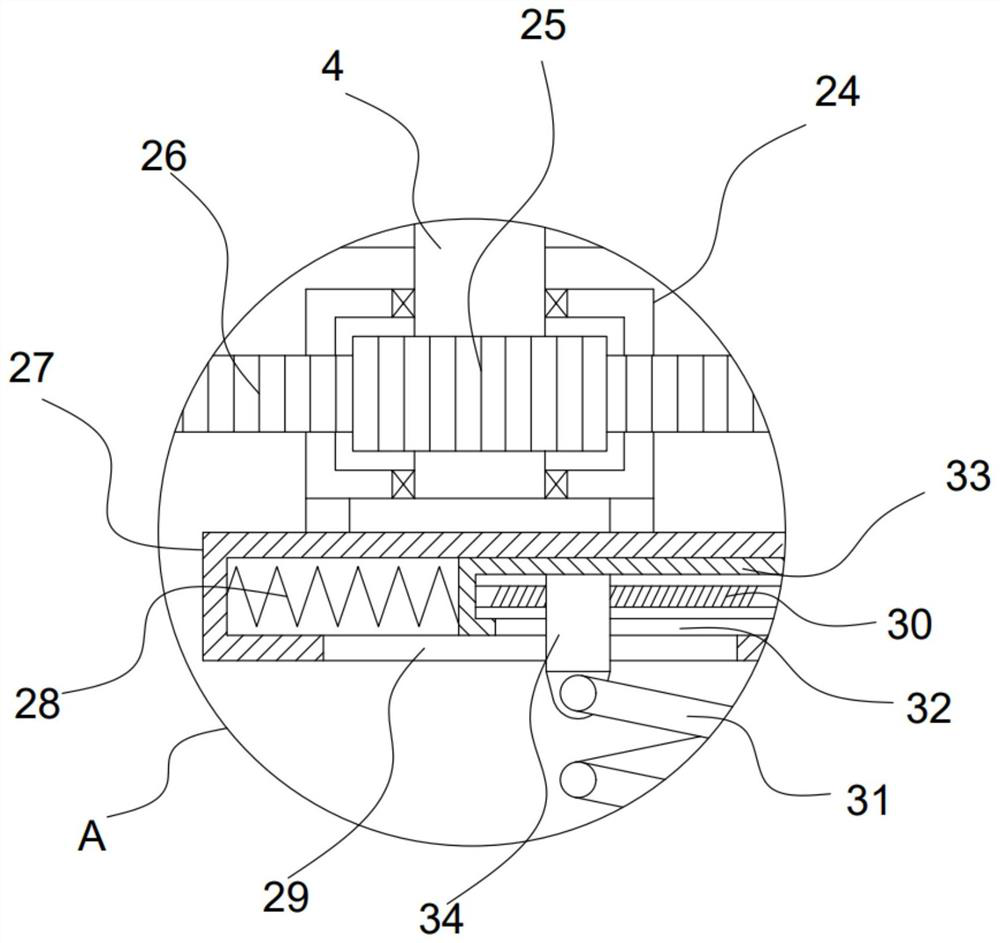

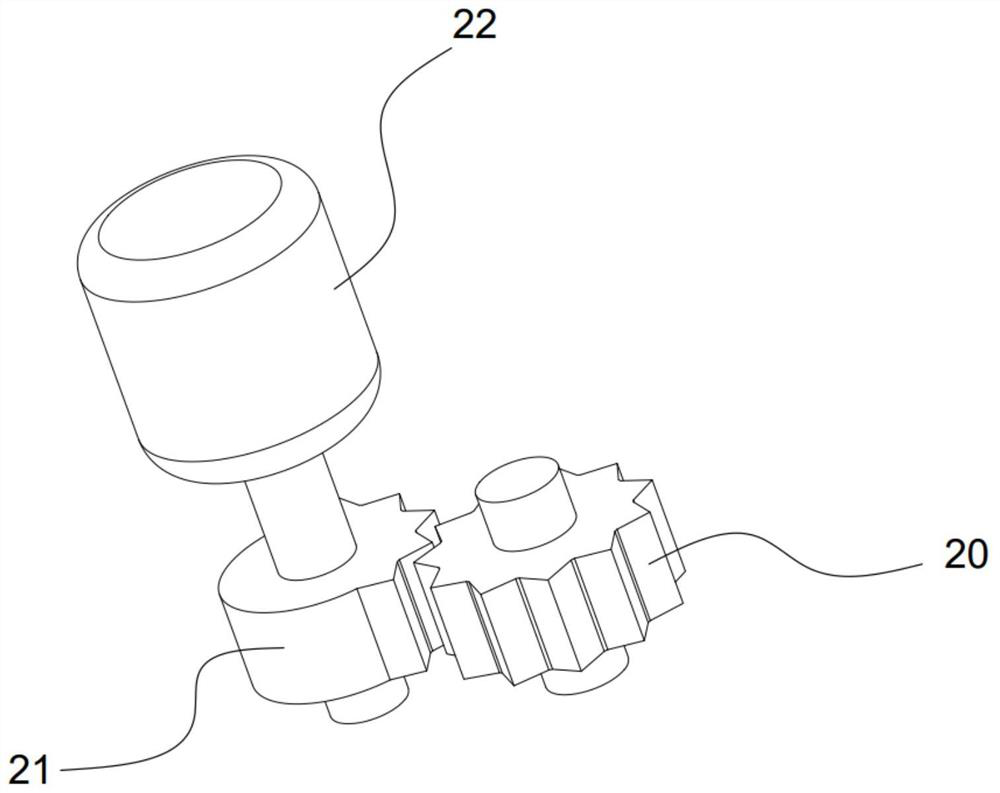

[0021] see Figure 1-3 , a self-propelled concrete maintenance device for water conservancy construction, comprising a walking frame 1, a transmission shaft 13 is installed in rotation on the bottom of the walking frame 1, a traveling wheel 12 is sleeved and fixed on the transmission shaft 13, and a horizontal adjustment is arranged on the walking frame 1 The horizontal adjustment mechanism is provided with a servo motor 6, and the servo motor 6 is driven and connected with a deflection mechanism. The bottom of the deflection mechanism is fixed with a guide sleeve 27, and a telescopic sleeve 33 is slidably installed in the guide sleeve 27. The bottom of the sleeve 33 is provided with a vertical lifting mechanism, the bottom of the vertical lifting mechanism is fixed with a sprinkler mechanism for spraying water on the concrete, and the driving motor 22 is fixed on the walking frame 1, and the driving motor 22 is connected by a transmission. It is a moving mechanism for driving...

Embodiment 2

[0026] On the basis of Embodiment 1, in addition, the spray mechanism of this device includes the water tank 7 fixed on the top of the walking frame 1 and the delivery pump 11 communicated with the water tank 7, and the outlet end of the delivery pump 11 communicates with a The shower plate 17 that is fixed on the bottom of the vertical lifting mechanism. The inside of the water tank 7 is used to store the clean water to be sprayed, and the delivery pump 11 is set to extract the clean water, and finally spray it downwards from the spray plate 17 to achieve the curing effect on the concrete.

[0027] The vertical lifting mechanism of the device includes two threaded rods 30 that are coaxially fixed in the telescopic sleeve 33 and have opposite screw threads. The ends of the threaded rods 30 are fixed with hand wheels II10. A threaded block 34 is sleeved, the guide sleeve 27 and the telescopic sleeve 33 are provided with a strip hole I29 and a strip hole II32 for the threaded bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com