A dumping device for kitchen waste

A technology for dumping device and kitchen waste, applied in water supply device, grease/oily substance/floating matter removal device, water/sewage multi-stage treatment, etc. It can solve the problems of oil and solid particles entering and increasing the blockage of sewage pipelines, etc. Achieve the effects of reducing adverse effects, facilitating disassembly and assembly, facilitating the cleaning of sundries and devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

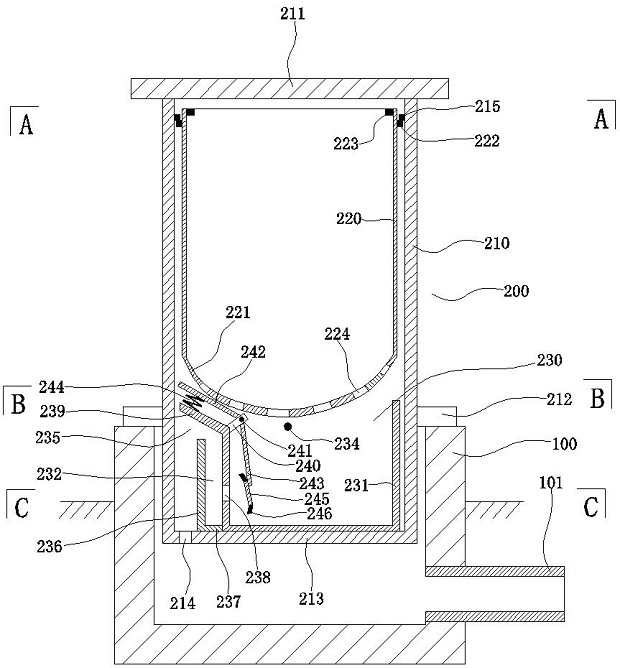

[0012] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4.

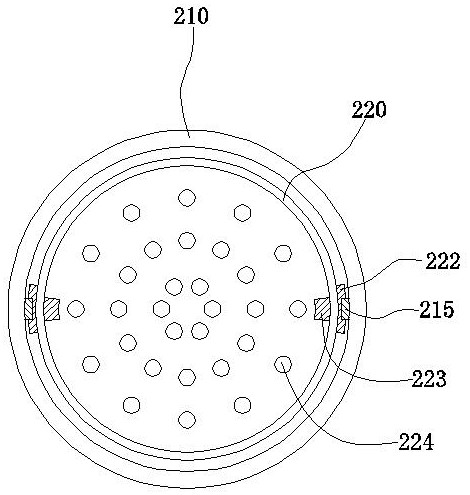

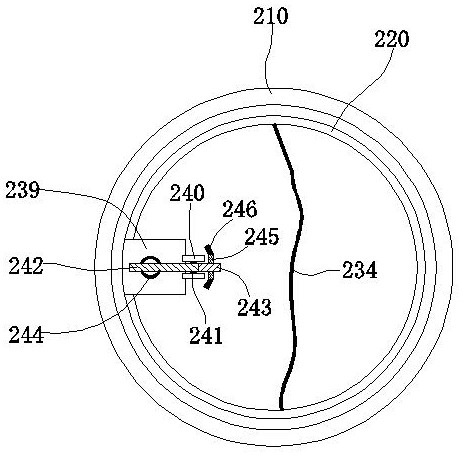

[0013] A dumping device for kitchen waste, comprising a sewage collection well 100 and a separation device 200 . The upper end of the collection well 100 is open, the upper part of the collection well 100 is exposed to the ground, and the lower side wall of the collection well 100 is connected to the sewage pipe 101 . Described separation device 200 comprises the barrel 210 that top is provided with cover 211, filter chamber 220 and separation mechanism 230, is provided with support block 212 on the outer wall of barrel 210, and support block 212 is placed on the top of collection well 100, barrel 210 bottom 213 A leak hole 214 is provided, and a stopper 215 is provided on the inner wall of the upper part of the bucket 210 . The filter chamber 220 is a hollow body with an upper end opening and a bottom plate 221 at the lower end,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com