A method for restoring the three-dimensional structure of nonwoven materials through the central axis of fibers

A non-woven material, three-dimensional structure technology, applied in the details, instruments, and calculations involving 3D image data, can solve problems such as loss of true fiber shape, loss of layer-to-layer connection, and difficulty in calculating the unique depth of surface points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

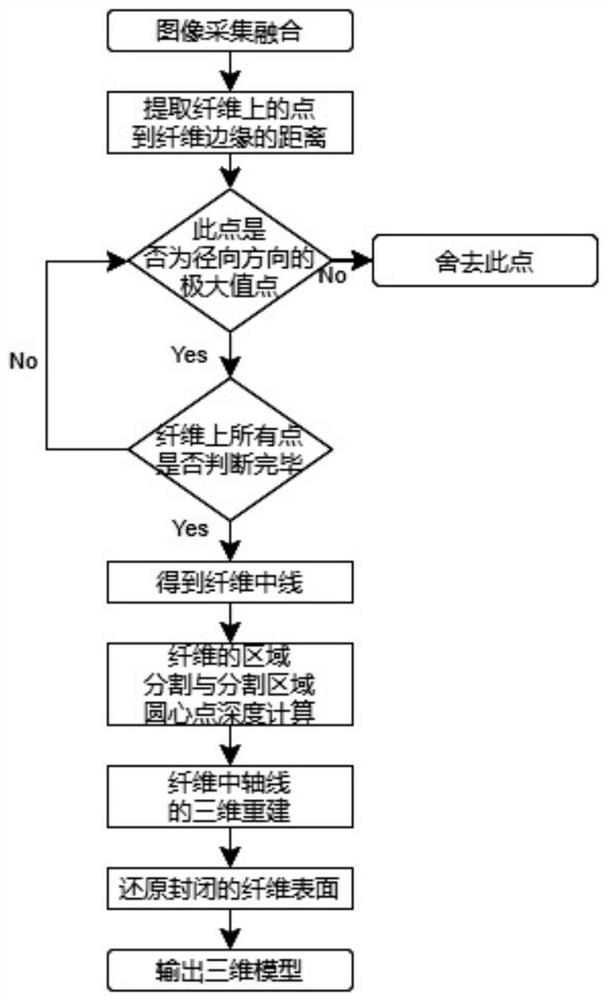

[0029] The invention provides a method for restoring the three-dimensional structure of non-woven materials through the central axis of fibers, such as figure 1 The schematic diagram of the flow shown, the specific steps are as follows:

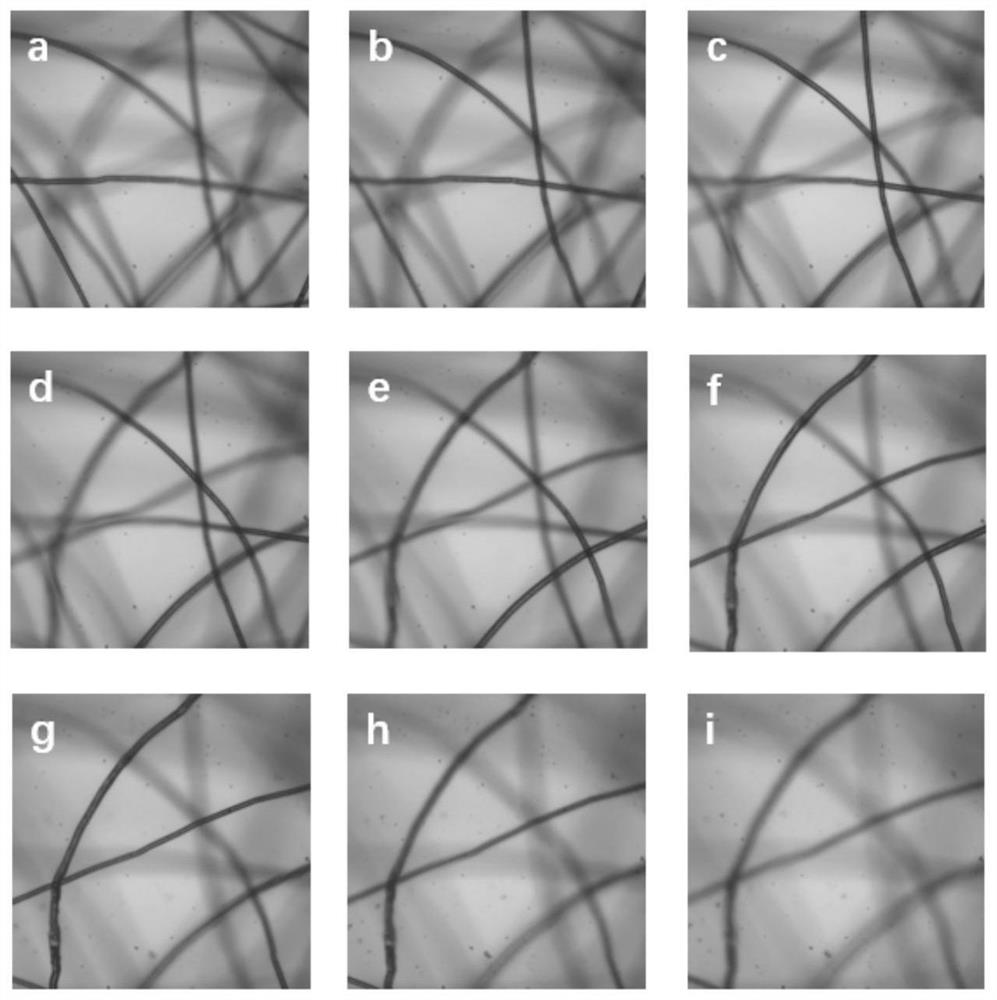

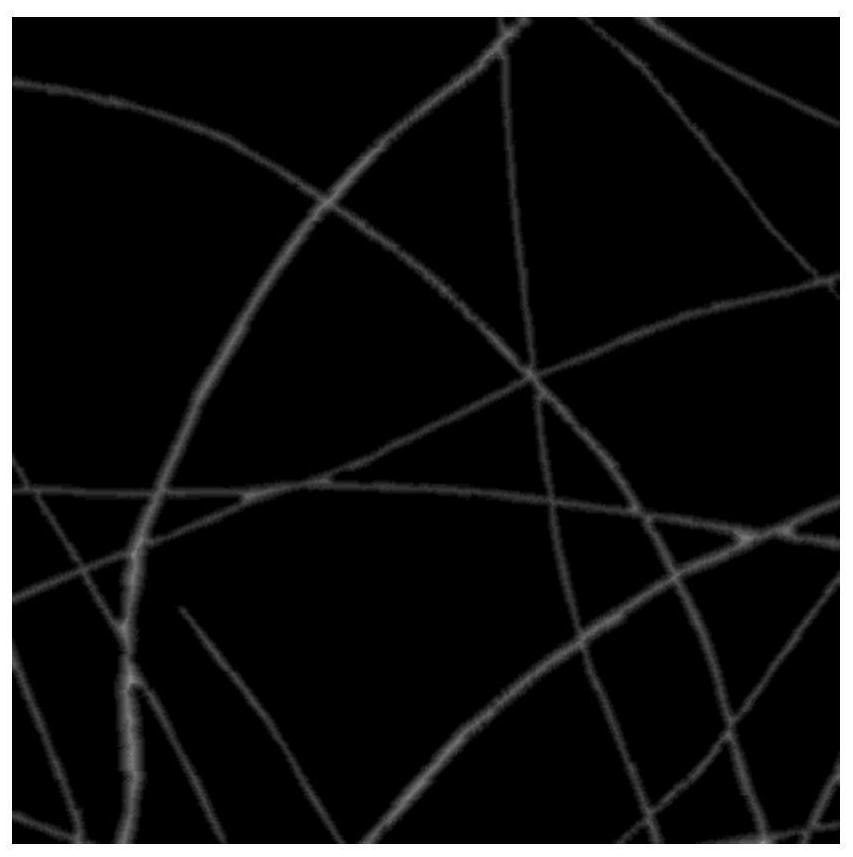

[0030] The first step, multi-layer microscopic image acquisition and fusion: use a fully automatic microscope equipped with an automatic stage to collect fusion images of multi-layer microscopic images under the same field of view and different focus positions, such as figure 2 During the focusing process under the same field of view, different foc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com