A crushing device for water conservancy and hydropower projects and its use method

A water conservancy, hydropower, and crushing device technology, which is applied in the direction of grain processing, etc., can solve the problems of affecting material crushing, affecting material crushing efficiency, and reducing the utilization rate of crushing rollers, and achieves the effects of easy removal, guaranteed pre-screening effect, and reduced occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

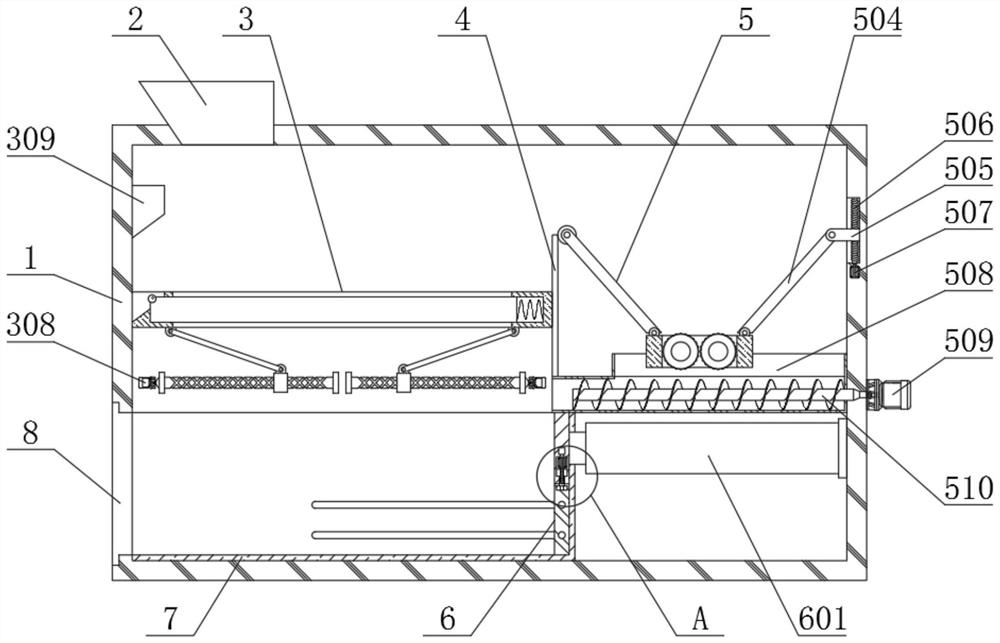

[0028] see Figure 1-5 , the present invention provides a technical solution:

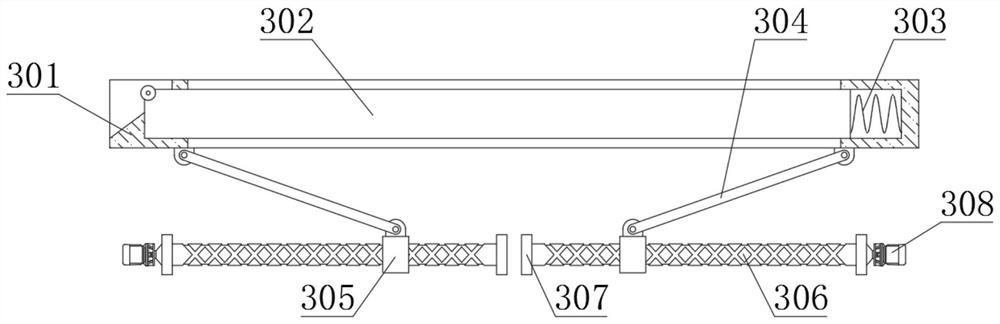

[0029] A crushing device for water conservancy and hydropower projects and its use method, comprising a crushing box 1, the top of the crushing box 1 is connected with a feed hopper 2, and the inner side of the crushing box 1 is fixedly connected with a partition 4. The material on the pre-screening mechanism 3 is blocked, and the left end of the dividing plate 4 is provided with a pre-screening mechanism 3, and the pre-screening mechanism 3 includes a lifting plate 301, a screening screen plate 302, a return spring 303, a transmission rod 304, a screw sleeve 305, Reciprocating lead screw 306, fixed block 307, first motor 308 and limit inclined block 309, lifting plate 301 is slidably connected between crushing box 1 and partition 4, and the inner side of lifting plate 301 is provided with screen mesh plate 302, partition The right end of 4 is provided with a deflection crushing mechanism 5, and t...

Embodiment 2

[0033] see Figure 1-5 , the present invention provides a technical solution:

[0034] A crushing device for water conservancy and hydropower projects and its use method, the same parts in embodiment 2 as in embodiment 1 will not be repeated in the present invention, and the difference lies in the working process.

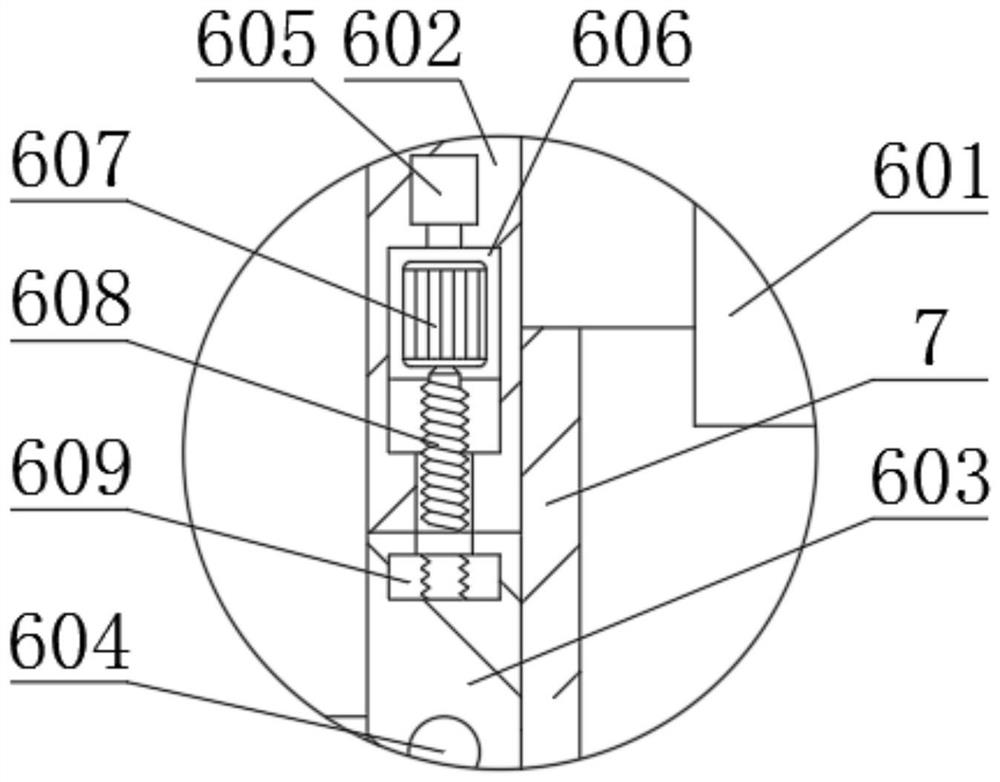

[0035] Workflow: When it is necessary to take out the material from the inside of the stacking box 7, the fourth motor 607 can be started, so that the fourth motor 607 drives the positioning screw 608 to rotate, and then the extension of the electric telescopic rod 605 drives the sliding seat 606 to move downward. Until the positioning screw 608 slides out from the bottom end of the tiling plate 602 and is inserted into the top inner side of the pushing plate 603, finally the positioning screw 608 is threaded with the screw groove block 609 to realize the fixing of the tiling plate 602 and the pushing plate 603 At this time, the elongation of the hydraulic push ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com