Steel stacking prevention device for 2# shear and operation process thereof

A technology of moving and manipulating arms, applied in the field of 2# shearing anti-piling steel device and its operation process, can solve the problems of steel stacking accident, head running around, affecting production time, etc., to prevent steel stacking, ensure quality, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

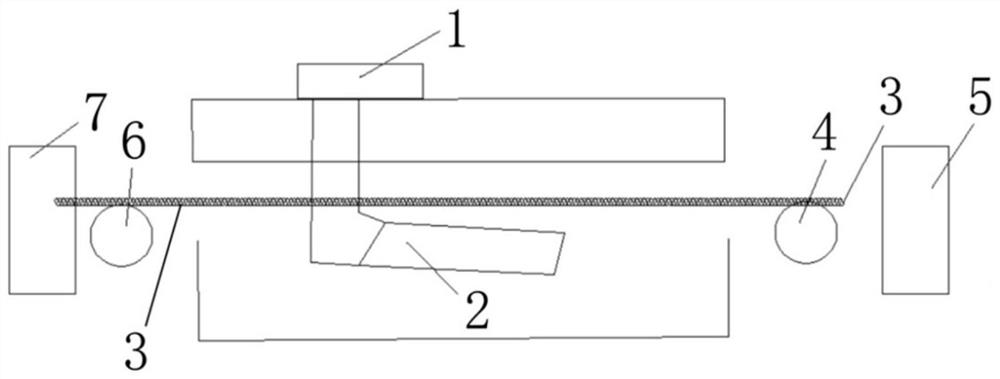

[0015] A 2# shear anti-stacking steel device, comprising more than one bar mill, 2# shears are arranged between the bar mills, such as figure 1 As shown, the middle part of the 2# shearing area is provided with an anti-stacking steel device, and the anti-stacking steel device includes an operating arm 2 and a control center 1, and the control center 1 is located on the roller table 3 in the 2# shearing area On one side, the operating arm 2 is a straight rod-shaped structure, and its fixed end is connected with the control center 1. When the operating arm 2 is in a non-working state, it is vertically downward. The middle part is controlled by the hydraulic system and can be folded and moved upwards by 90°, and its movable end is the moving end; when the operating arm moves upwards by 90°, the end of the moving end is located in the middle of the roller table 3 .

[0016] A preferred solution, the length of the operating arm is 100±10cm.

[0017] In this embodiment, the 2# shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com