Die-casting machine discharging device for piston production

A die-casting machine and piston technology, which is applied in the field of die-casting machine blanking device for piston production, and can solve problems such as troublesome removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

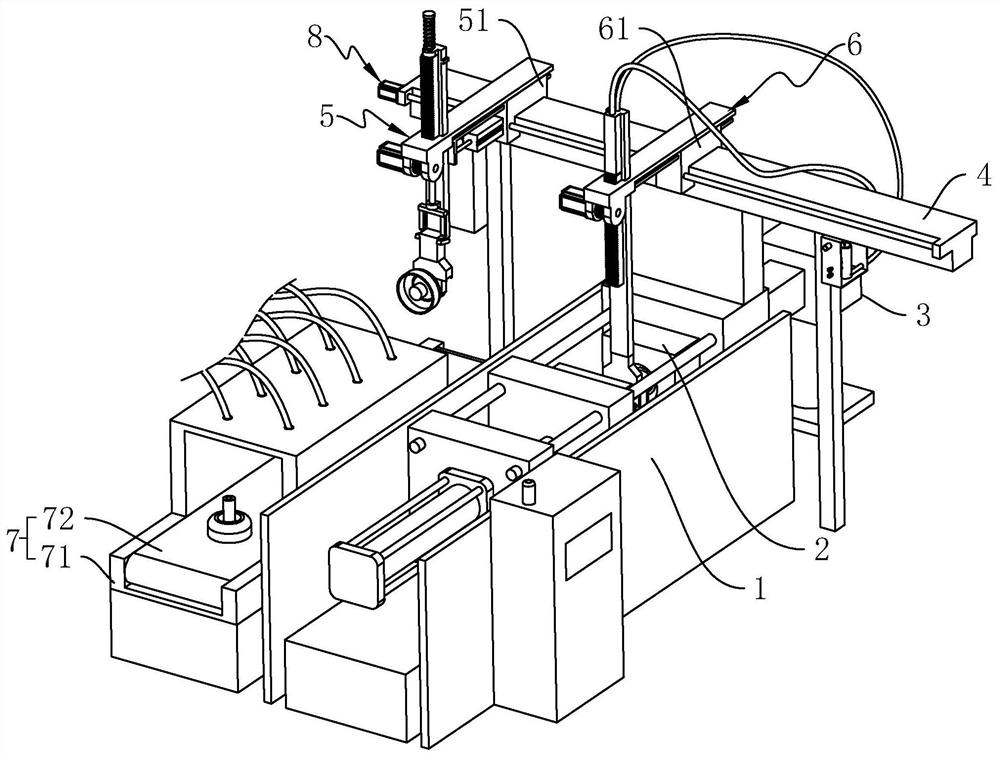

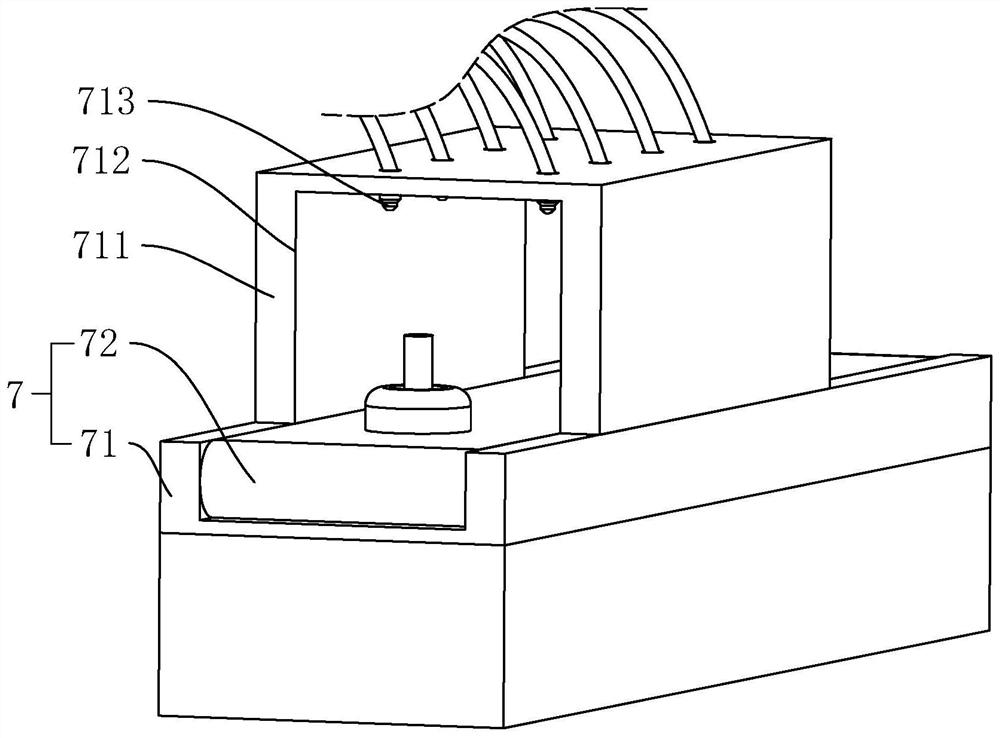

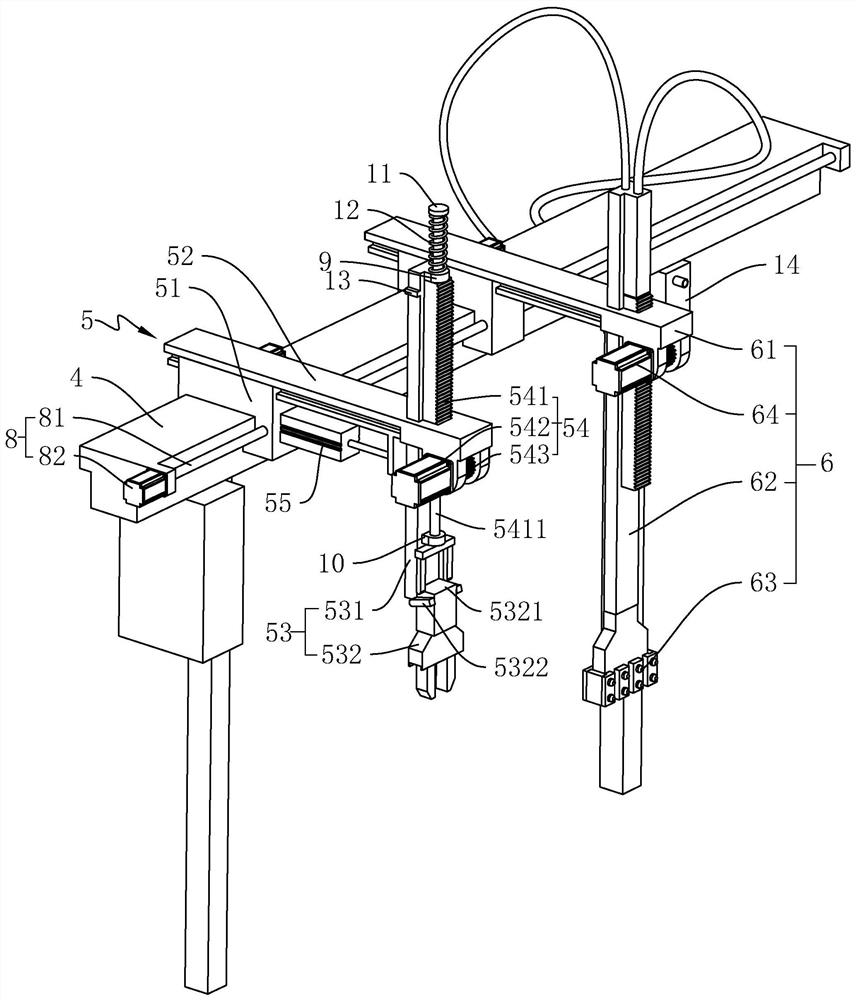

[0042] The following is attached Figure 1-7 The application is described in further detail.

[0043] Such as figure 1 As shown, there is a die-casting machine 1 in the related art, and a molding die 2 is provided on the die-casting machine 1 for forming a workpiece. Die-casting machine 1 is the prior art, which is a series of industrial casting machines that hydraulically inject molten metal into the forming mold 2 under pressure for cooling and forming. The forming mold 2 includes a movable mold and a fixed mold, and a series of solid metal castings are obtained after the mold is opened. . One end of the die-casting machine 1 is provided with a soup feeder 3 , through which liquid aluminum is filled into the die-casting machine 1 so as to enter the mold cavity of the forming mold 2 .

[0044] The embodiment of the present application discloses a die-casting machine blanking device for piston production, such as figure 1 , including a support frame 4, and the support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com