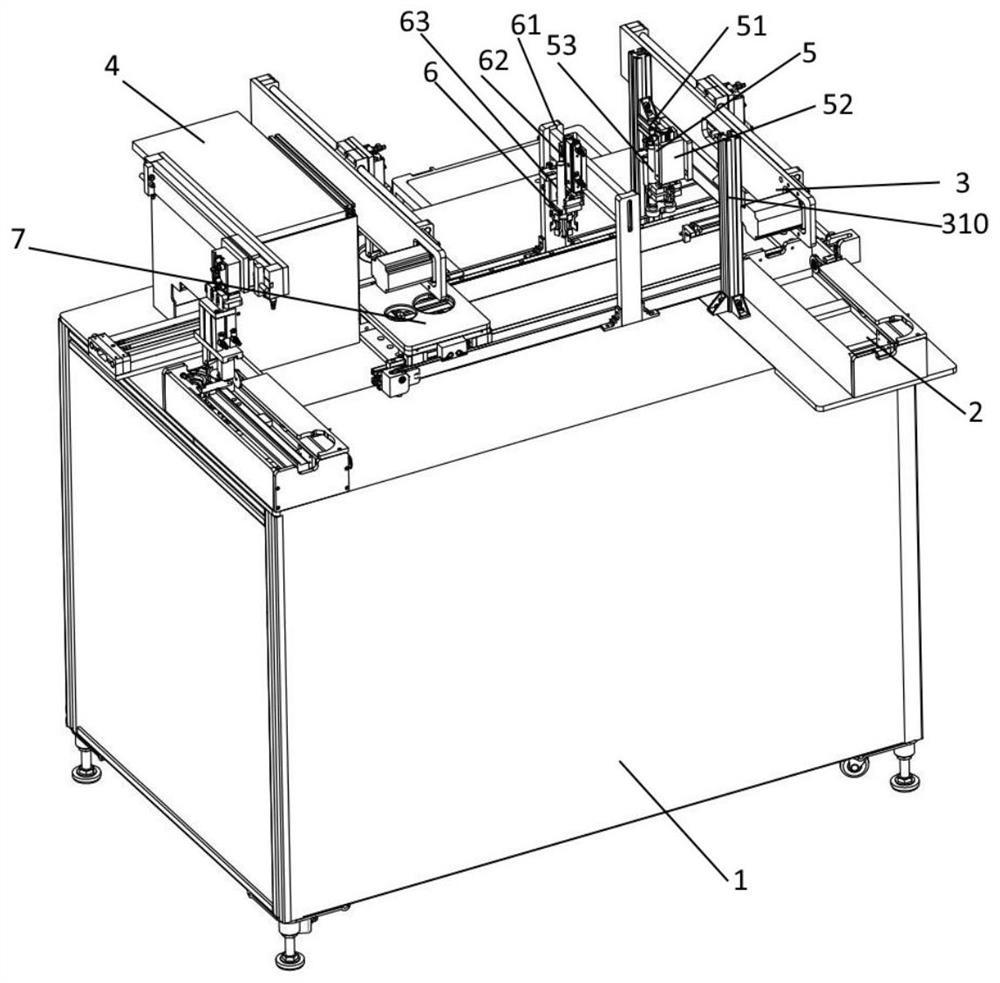

Flaw detection device based on visual sensor and detection method thereof

A visual sensor and defect detection technology, which is applied to grinding drive devices, machine tools suitable for grinding workpiece edges, and parts of grinding machine tools, etc., can solve problems such as deformation of cylindrical pipes, failure of detection results, etc. , to ensure the accuracy and reduce the effect of detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

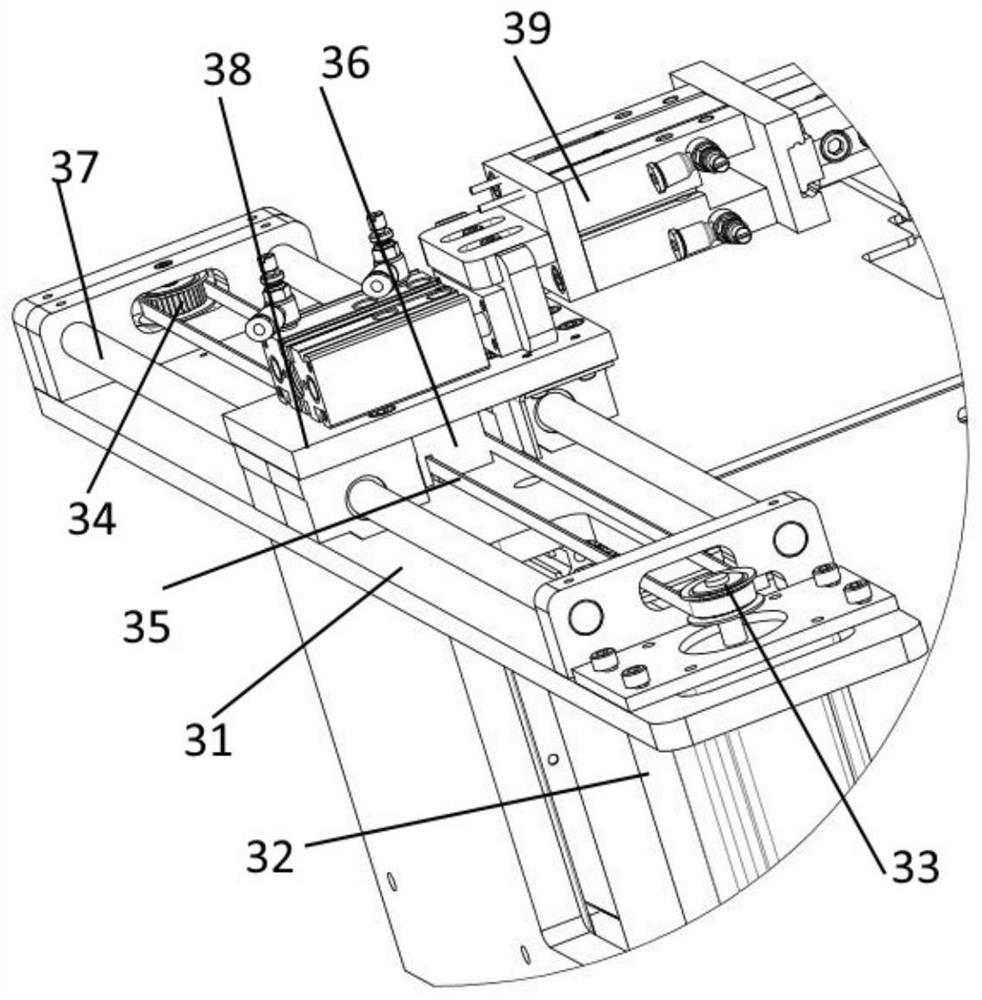

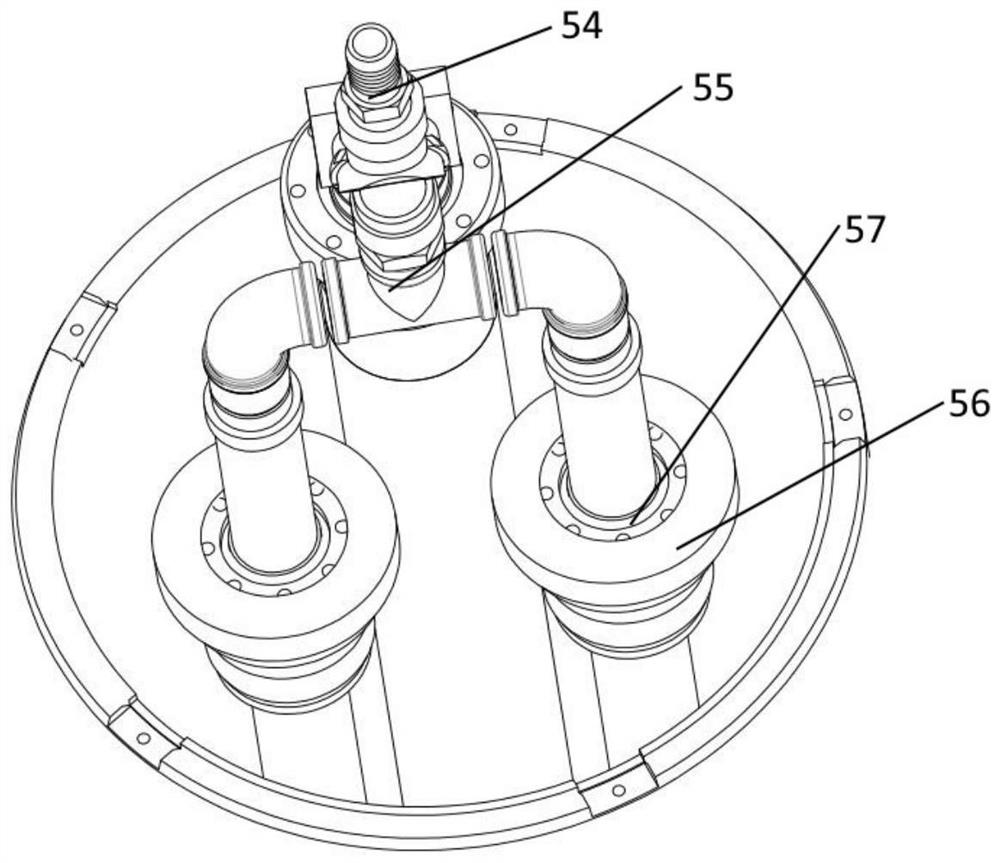

[0034] After the applicant's research and analysis, the reason for this problem (the visual sensor will extract the wrong features of the target from the deformed columnar pipeline, which will lead to the failure of the detection result) is that the existing detection device is performing the inspection on the inner wall of the columnar pipeline. During the detection work, it is necessary to penetrate the visual detection device on the detection device into the interior of the columnar pipe, and then rotate the visual detection device to complete the inspection of the inner wall of the columnar pipe. However, when the thickness of the cylindrical pipe is thin or the texture is soft, At this time, the columnar pipe placed on the loading platform will be deformed, and when the detection device detects the deformed columnar pipe, the visual sensor will detect the deformed Extracting the wrong features of the target will lead to the failure of the detection results; in order to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com