Reworking method for nanocrystalline alloy magnetic core

A technology of nanocrystalline alloy and magnetic core, which is applied in manufacturing tools, inductance/transformer/magnet manufacturing, heat treatment equipment, etc. It can solve the problems of constant 10KHz inductance value, poor inductance, large economic loss, etc., and improve the utilization rate of materials , The effect of reducing scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

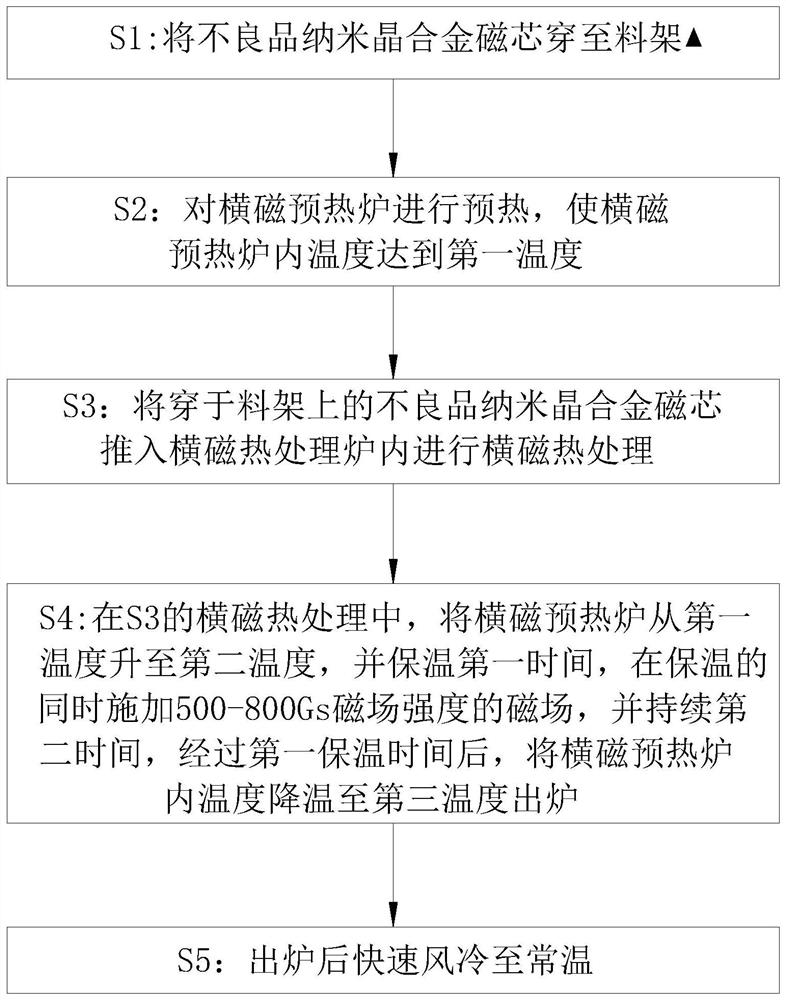

[0025] Such as figure 1 As shown, a method for reworking a nanocrystalline alloy magnetic core, the specific steps are:

[0026] S1: Pass the defective nanocrystalline alloy core to the rack;

[0027] S2: Preheating the transverse magnetic preheating furnace so that the temperature in the transverse magnetic preheating furnace reaches the first temperature;

[0028] S3: push the defective nanocrystalline alloy magnetic core worn on the rack into the transverse magnetic heat treatment furnace for transverse magnetic heat treatment;

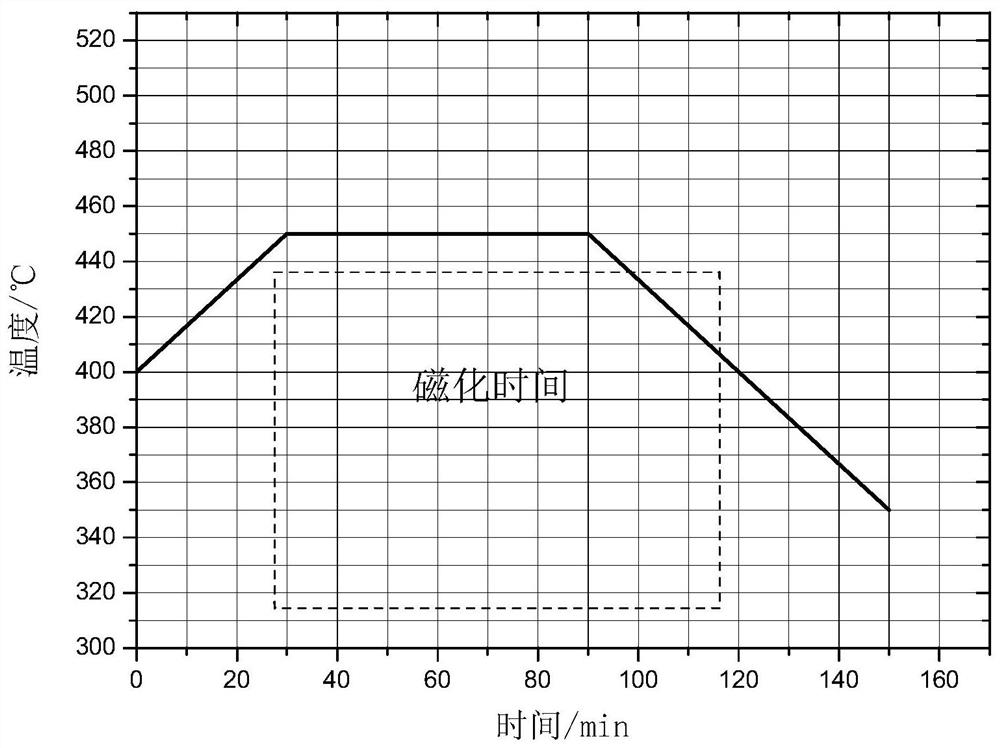

[0029] S4: In the transverse magnetic heat treatment of S3, raise the transverse magnetic preheating furnace from the first temperature to the second temperature, and keep it warm for the first time, and apply a magnetic field with a magnetic field strength of 500-800Gs while keeping warm, and last for the second time , after the first holding time, the temperature in the transverse magnetic preheating furnace is lowered to the third temperature ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap