Implementation method of pressure self-tightening sealing structure

A self-tightening sealing and pressure technology, applied in geometric CAD and other directions, can solve problems such as the inability to quantitatively calculate the degree of self-tightening, cumbersome design calculations, and long design cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] A parametric design method of a pressure self-tightening sealing structure of the present invention, the specific operation steps are as follows:

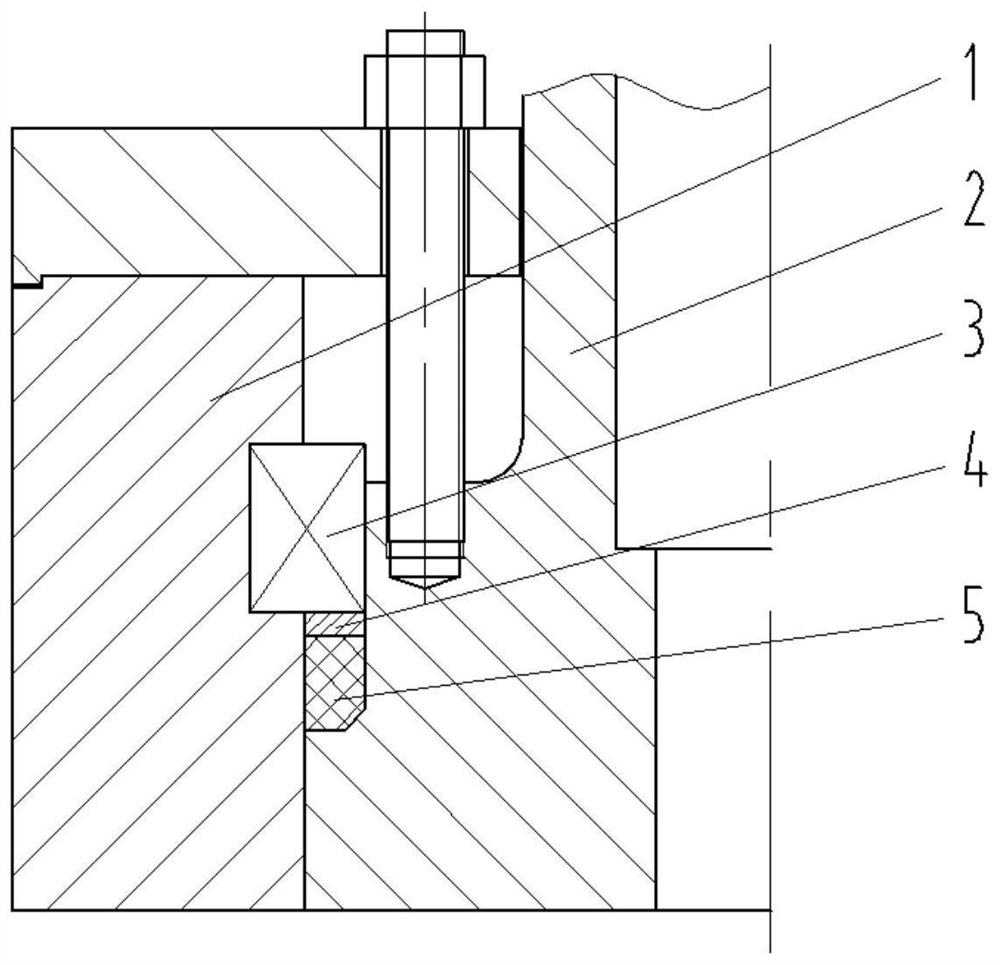

[0018] Step 1: Use CAD software to create a two-dimensional geometric model of the pressure self-tightening seal structure, and determine the valve body (1), stuffing box (2), four open rings (3), gaskets (4), and seals in the pressure self-tightening seal structure. The geometric relationship between the circles (5), see Figure a for details;

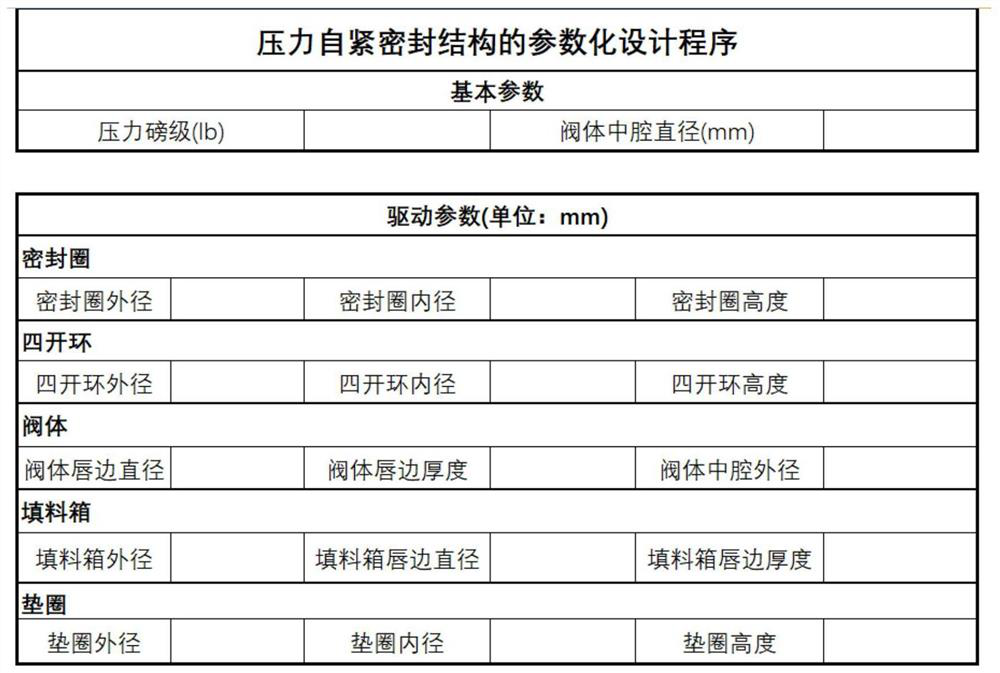

[0019] Step 2: Obtain the geometric parameters of the pressure self-tightening seal structure, and determine the basic parameters and driving parameters of the parametric design;

[0020] Step 3: Add basic parameters and driving parameters in the EXCEL software interface, write the functional relationship between the basic parameters and driving parameters, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com