Painting equipment for furniture production

A technology for equipment and furniture, applied in the field of painting equipment for furniture production, can solve the problems of easy rotation of the brush, easy sticking of rolling, uneven painting, etc., and achieve the effect of reducing joint marks, rolling smoothly, and improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

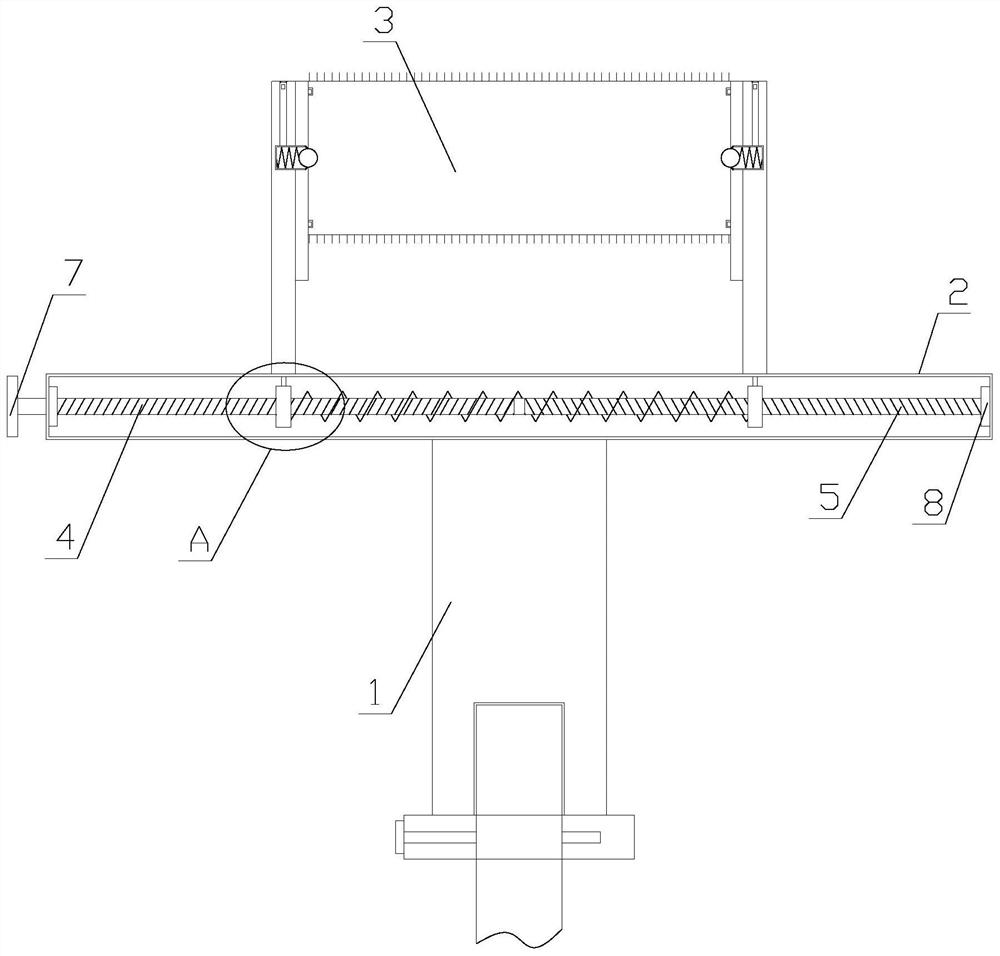

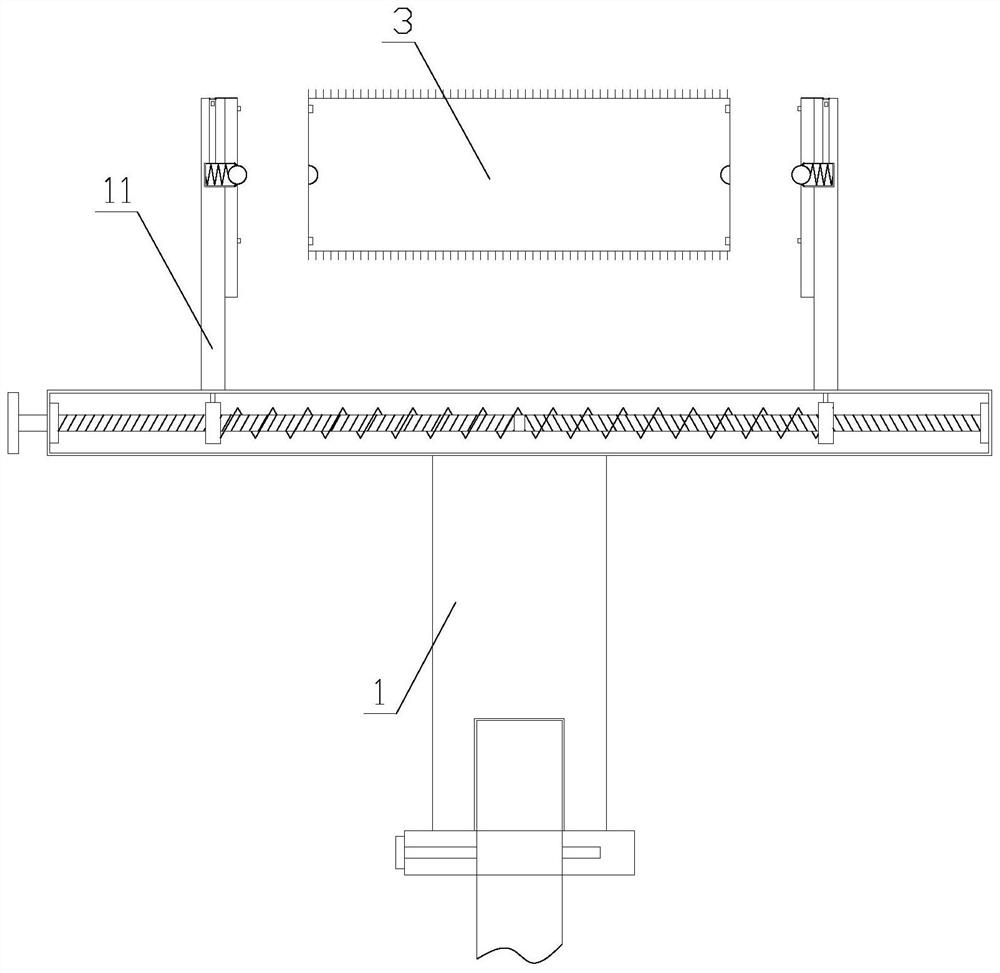

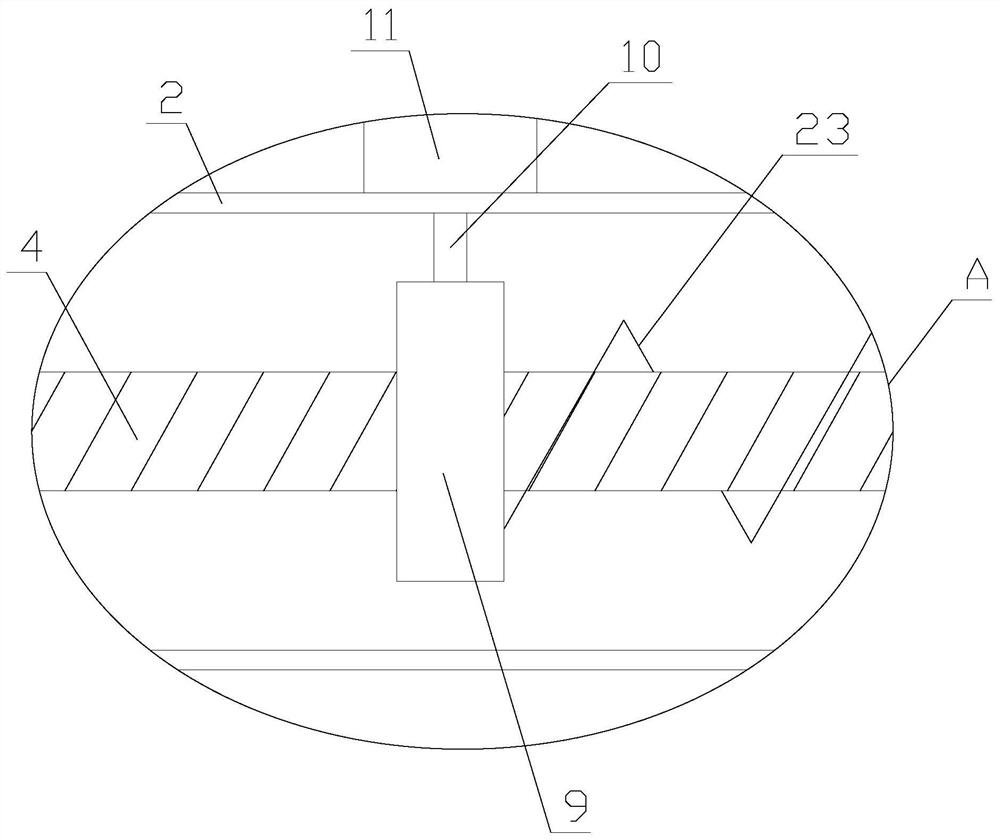

[0027] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0028] Such as Figure 1-2 As shown, a painting equipment for furniture production includes a fixed rod 1, a rectangular block 2, a limit mechanism and a connecting mechanism, the rectangular block 2 is arranged horizontally, and the fixed rod 1 is vertically arranged on the Below, the top of the fixed rod 1 is connected to the middle of the rectangular block 2 , the connecting mechanism is arranged at the end of the fixed rod 1 away from the rectangular block 2 , and the limiting mechanism is arranged above the rectangular block 2 .

[0029] The hairbrush 3 of different sizes is adjusted by the limiting mechanism, so that when the furniture is painted, one-t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap