Adjustable square steel grooving equipment

A slotting equipment, adjustable technology, applied in the direction of metal processing equipment, forming tools, feeding devices, etc., can solve the problem of inconvenient waste collection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

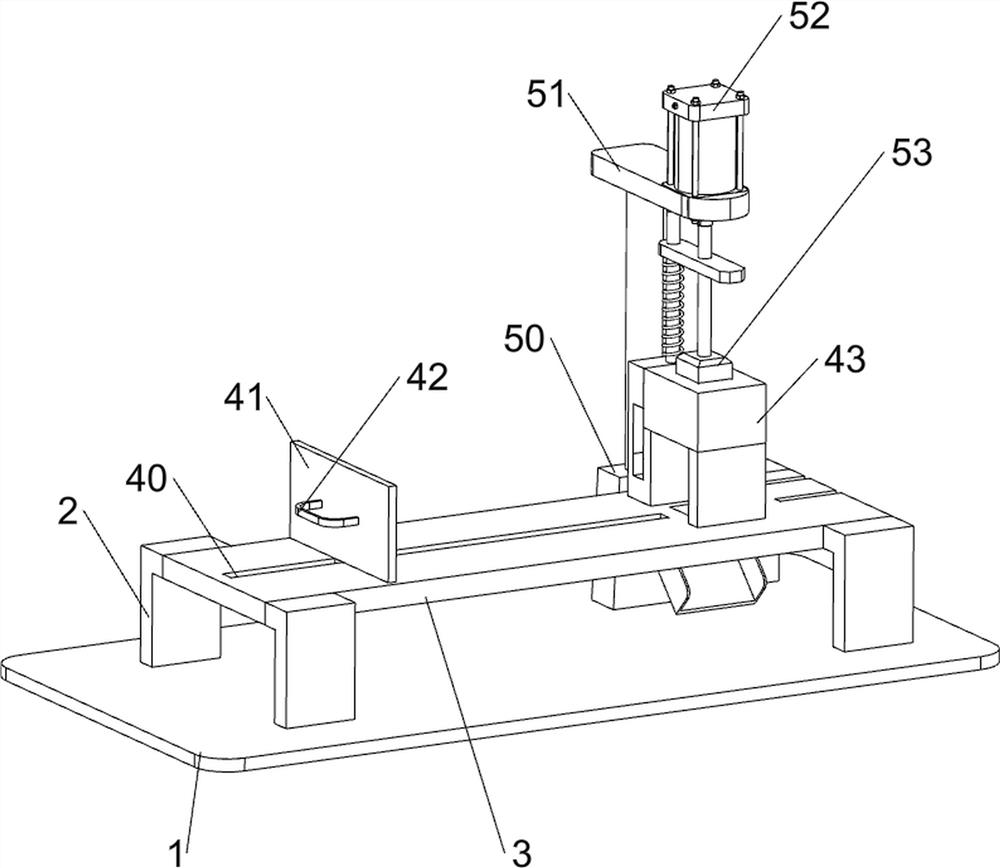

[0026] An adjustable square steel grooving equipment such as figure 1 and figure 2 As shown, it includes a base plate 1, a support 2, a workbench 3, a placement mechanism 4 and a slotting mechanism 5. The base plate 1 is provided with a plurality of supports 2, and a workbench 3 is arranged between the supports 2. On the workbench 3, there are The placement mechanism 4 is provided with a slotting mechanism 5 on the workbench 3 .

[0027] When people need to use this equipment, first people place the square steel on the workbench 3 between the placement mechanism 4, then people adjust the position of the square steel so that the right end of the square steel is tightly positioned under the slotting mechanism 5, and then people can Start the slotting mechanism 5 to make the slotting mechanism 5 operate on the upper and lower sides of the opposite steel for slotting. When the slotting mechanism 5 completes the slotting of the opposite steel and is away from the square steel, pe...

Embodiment 2

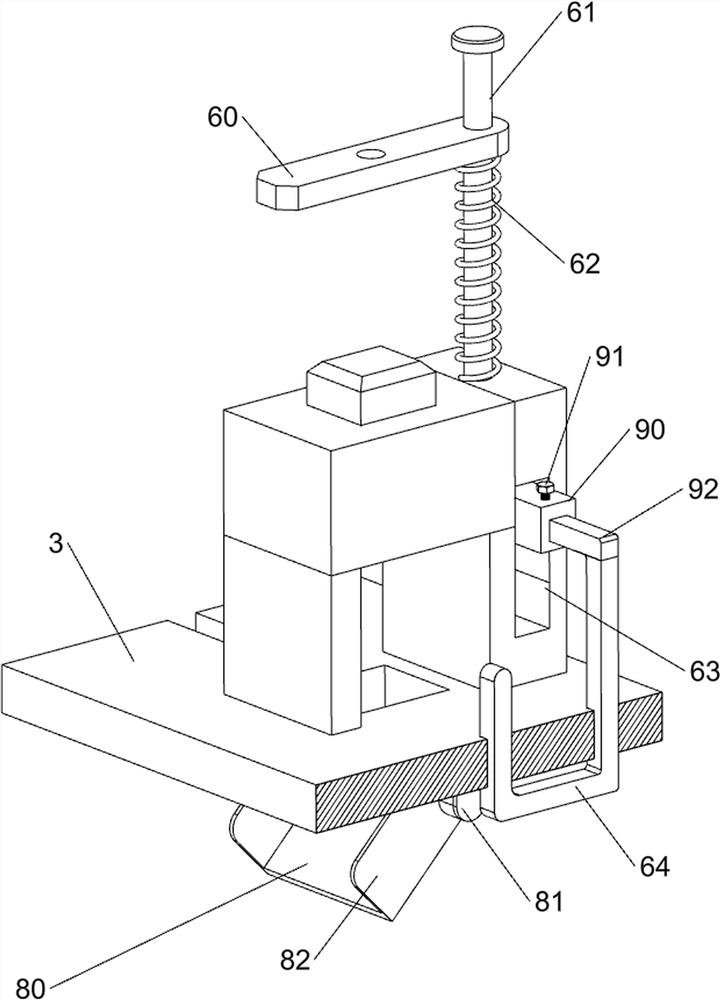

[0032] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 and Figure 5 Shown, also comprise limit mechanism 6, limit mechanism 6 comprises mounting plate 60, connecting rod 61, first spring 62 and limit rod 64, is provided with mounting plate 60 on cylinder 52 expansion rods, is provided with mounting plate 60 Connecting rod 61 is arranged, and connecting rod 61 is slidably connected with N-type block 43, and first spring 62 is sleeved on connecting rod 61, and first spring 62 is connected with N-type block 43 and mounting plate 60, and N-type block 43 is provided with The sliding groove 63 on the right side of the workbench 3 is provided with a limit rod 64 .

[0033] First, people move the limit rod 64 upwards, so that the limit rod 64 limits the position of the square steel, and then when the cylinder 52 telescopic rod moves downward, the cylinder 52 telescopic rod drives the mounting plate 60 and the connecting rod 61 to move downward. A spring 62 was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com