Punching equipment for connector

A technology of punching equipment and connectors, applied in drilling/drilling equipment, metal processing equipment, boring/drilling and other directions, can solve problems such as affecting punching efficiency, multi-manpower and time, and reduce operational troubles , The effect of preventing damage and reducing the trouble of collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

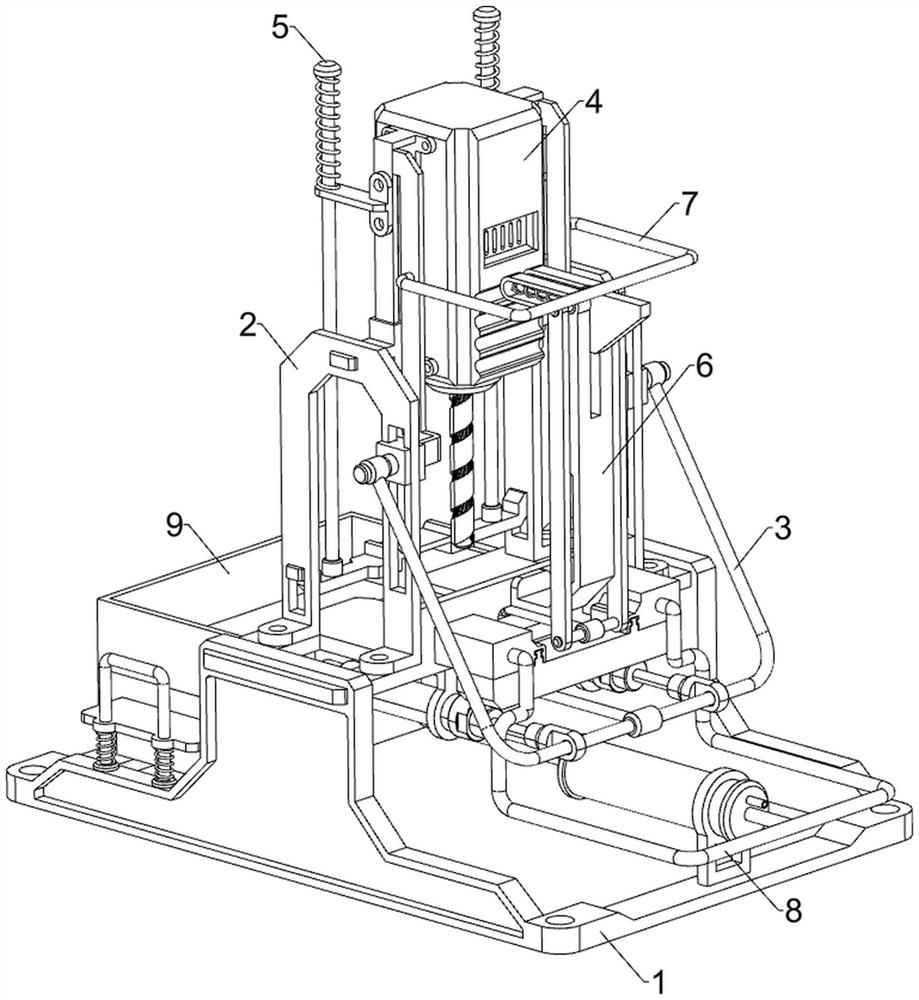

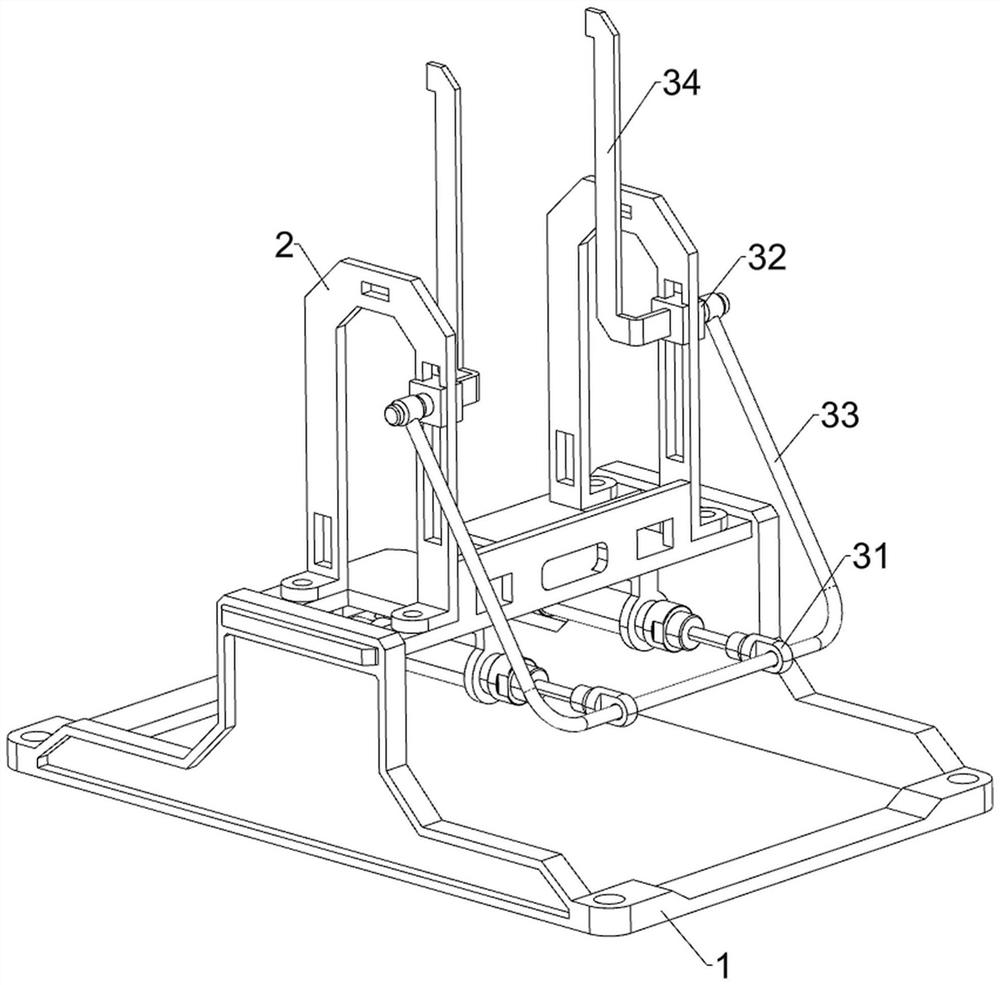

[0030] A punching device for connectors such as Figure 1 to Figure 3 As shown, it includes a bracket 1, a support plate 2, a drive assembly 3 and a drilling assembly 4. The support plate 2 is fixed on the front and rear sides of the upper part of the support 1 through bolts, and the drive assembly is arranged between the support plate 2 and the bracket 1. 3. A drilling assembly 4 is provided between the support plates 2 .

[0031] When the connector needs to be drilled, the connector is placed on the bracket 1, and then the driving component 3 is started, the driving component 3 will drive the drilling component 4 to operate, and then the drilling component 4 will punch the connector , when the connector punching is completed, control the driving assembly 3 to operate in reverse, so that the drilling assembly 4 operates in reverse and resets, and then replace another connector on the bracket 1, and then repeat the above operation, when all the connectors are all After the pu...

Embodiment 2

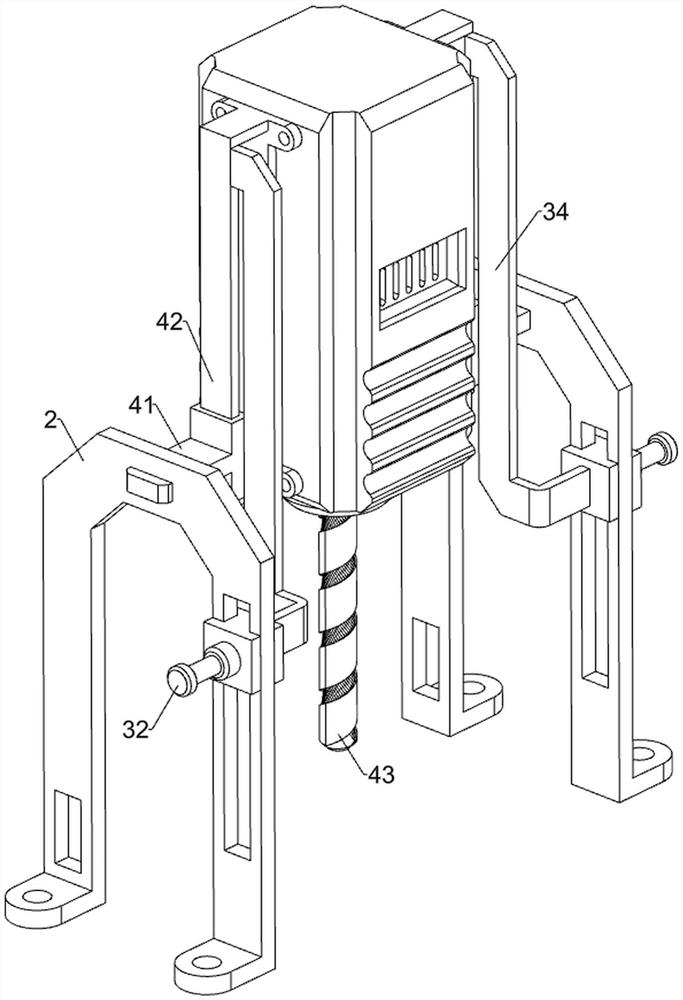

[0037] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, it also includes a pressing assembly 5, and the pressing assembly 5 includes a guide plate 51, a vertical bar 52, a first spring 53 and a pressing plate 54, and the slide rail 42 is fixed with a guide plate 51 by bolts, and the guide plate 51 A vertical rod 52 is slidably connected to the top, a first spring 53 is connected between the vertical rod 52 and the guide plate 51 , and a pressing plate 54 is welded between the lower sides of the vertical rod 52 .

[0038] When the slide rail 42 moves downward, it will drive the guide plate 51, the vertical bar 52, the first spring 53 and the pressing plate 54 to move downward together. When the pressing plate 54 moves to contact with the bracket 1 and the connector, the pressing plate 54 and the vertical bar 52 No longer moving down, the guide plate 51 will continue to move down, and then the first spring 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com