Noise isolation device for building tapping

A technology for noise and holes, applied in the field of isolation devices, can solve problems such as excessive physical strength, large noise, and cost, and achieve the effect of reducing noise, reducing noise, and increasing noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

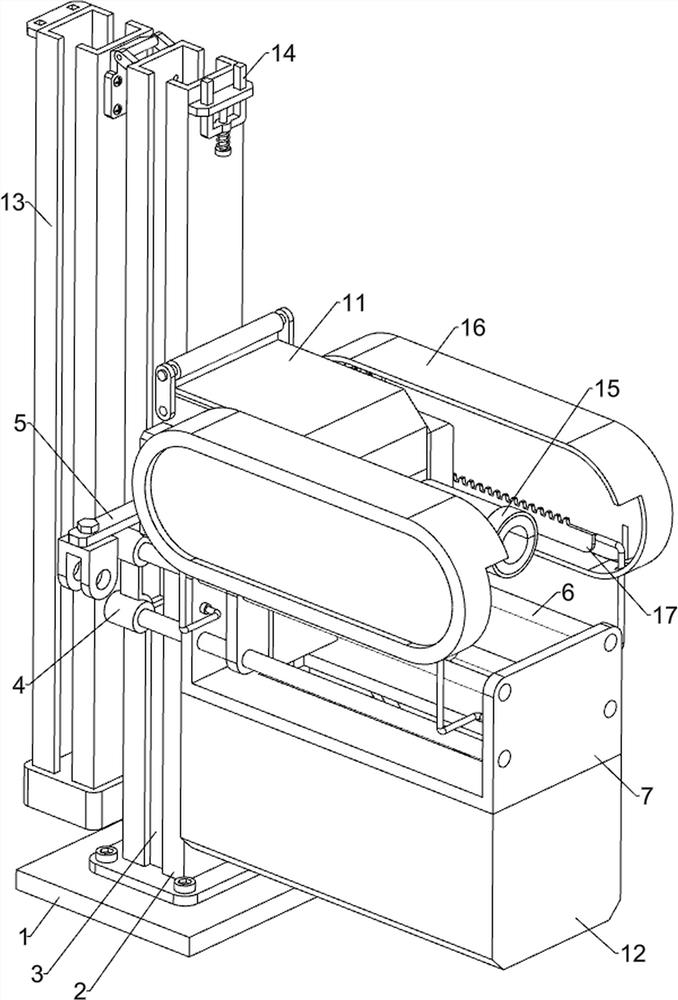

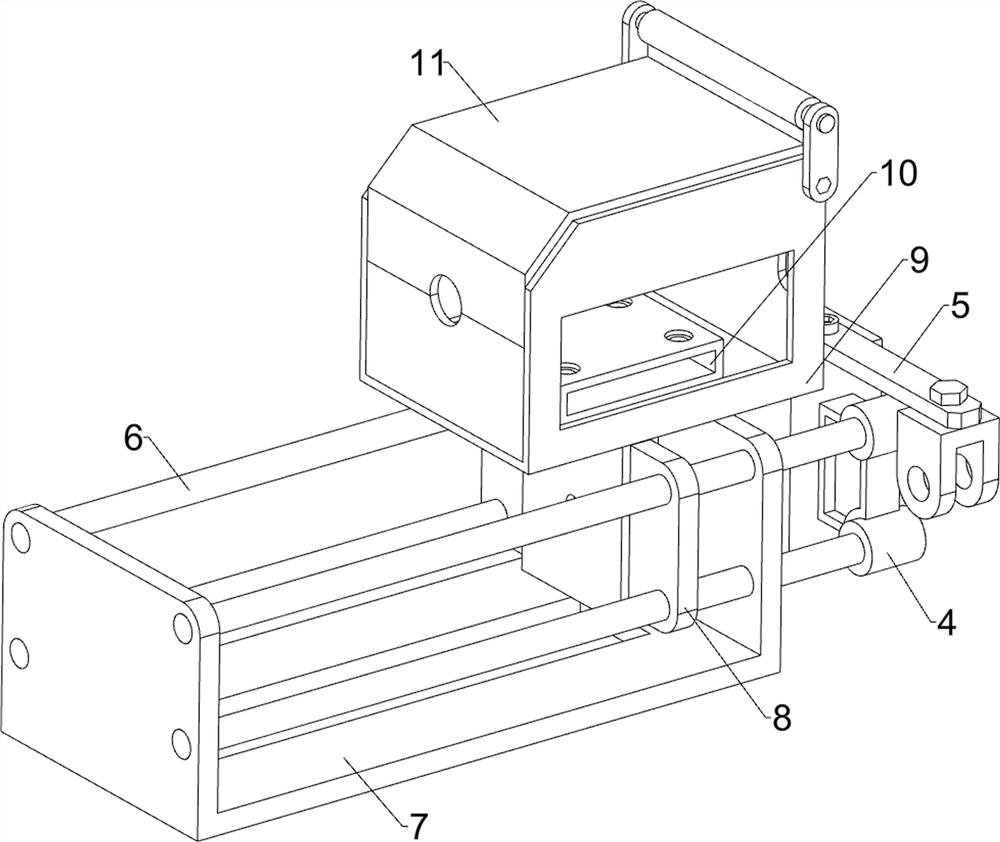

[0036] A noise insulation device based on building openings, such as Figure 1-9 As shown, it includes a bottom plate 1, a guide frame 2, a support block 3, a first sliding block 4, a connecting frame 5, a cross bar 6, a frame plate 7, a first sliding plate 8, an airtight frame 9, a mounting frame 10, and a cover plate 11. The moving assembly 12 and the extension assembly 13, the upper side of the bottom plate 1 is fixed with a guide frame 2 through bolts, the lower side of the guide frame 2 is provided with a support block 3, and the inner side of the guide frame 2 is slidingly provided with a first sliding block 4 , the first sliding block 4 is in contact with the support block 3, the upper side of the first sliding block 4 is connected with a connecting frame 5, the front and rear sides of the connecting frame 5 are provided with bolt holes, and the upper and lower sides of the left part of the first sliding block 4 are The front and back are symmetrically connected with cr...

Embodiment 2

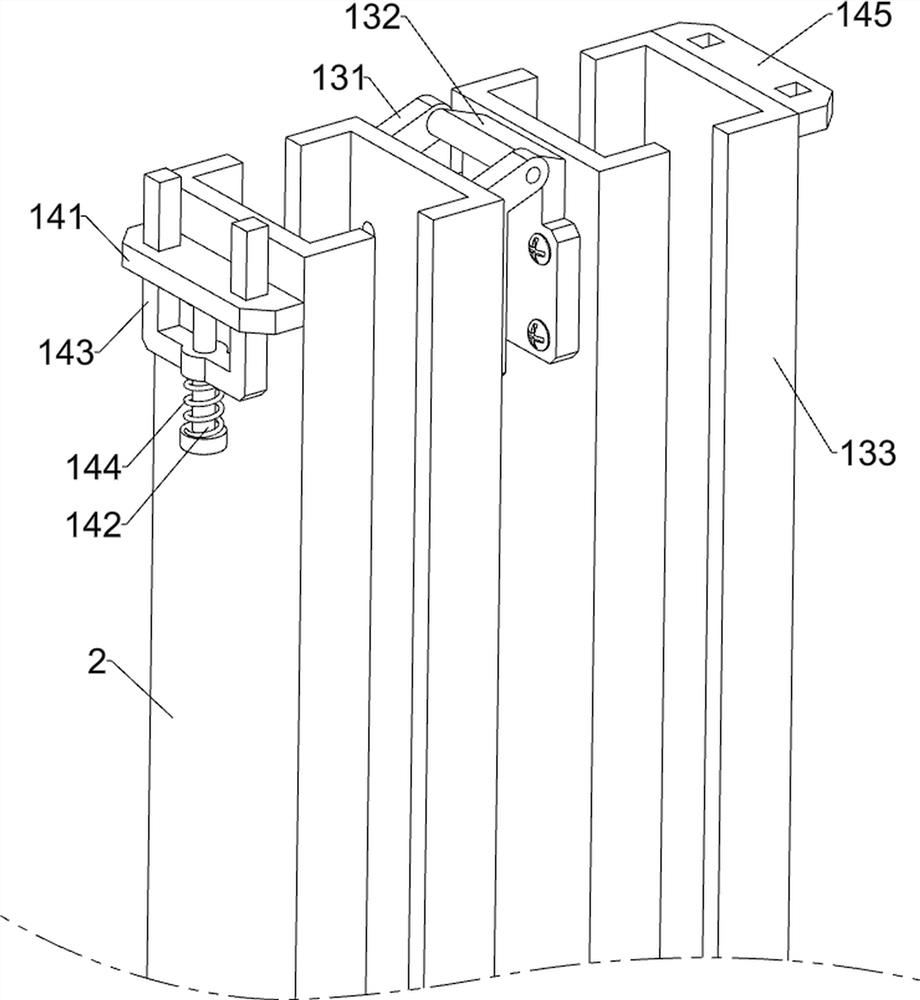

[0043] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 As shown, it also includes a fixed assembly 14, the fixed assembly 14 includes a guide plate 141, a guide rod 142, an insert block 143, a second spring 144 and a clamping plate 145, the upper left side of the guide frame 2 is connected with a guide plate 141, the guide The lower side of the plate 141 is connected with a guide rod 142, the guide rod 142 is slidably connected with an insert 143, the two ends of the insert 143 are slidably connected with the guide plate 141, and the bottom of the insert 143 is connected with the bottom of the guide rod 142. A second spring 144 is connected between them, and a clamping plate 145 is connected to the upper right side of the elongated frame 133 , and the clamping plate 145 cooperates with the inserting block 143 .

[0044] When the height of the guide frame 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com