A kind of steel cold sawing process

A technology of cold sawing and sawing, which is applied in the direction of metal sawing equipment, manufacturing tools, sawing machine devices, etc., which can solve the problems of low utilization rate of cold sawing, improve production capacity, reduce the number of sawing times, and improve the utilization rate of cold sawing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

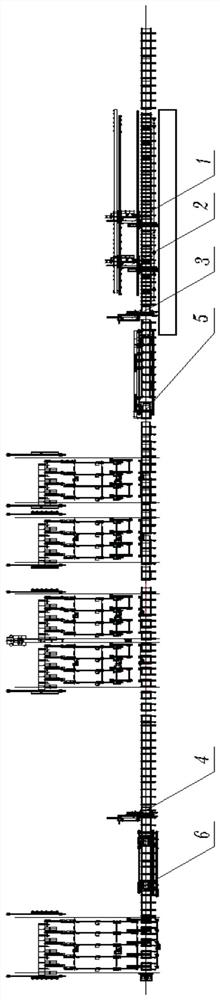

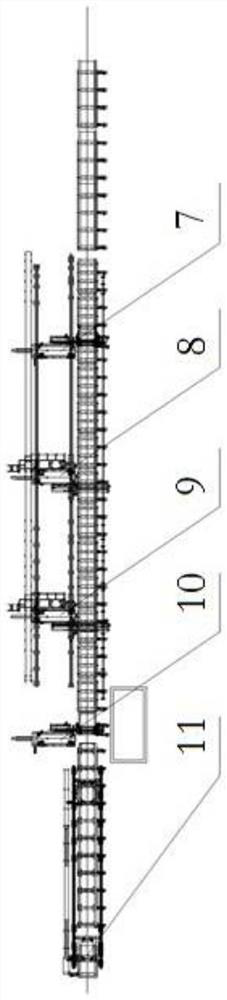

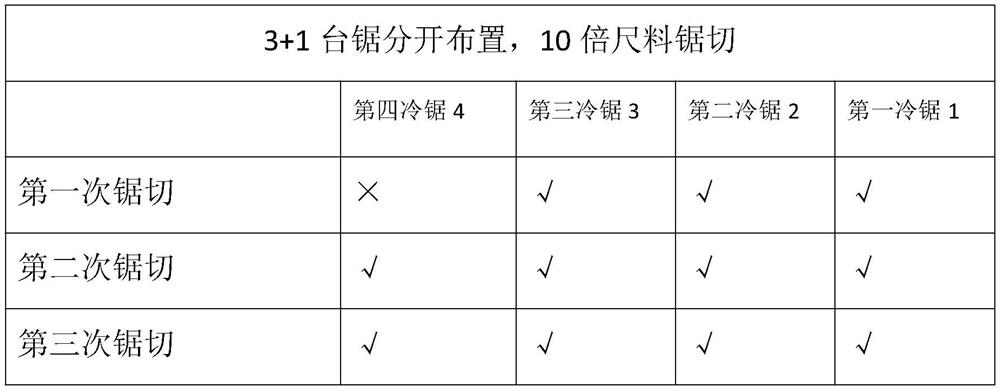

[0028] like figure 1 As shown, a section steel cold sawing process adopts an N+1 arrangement process. When N=3, that is, three cold saws are arranged in the first sawing area. The first cold saw 1, the second cold saw 2, the third cold saw 3, the first fixed-length baffle 5, the fourth cold saw 4 and the second fixed-length baffle 6 are arranged in sequence from right to left, and all are set. Above the roller table; wherein the first cold saw 1, the second cold saw 2, the third cold saw 3, and the first fixed-length baffle 5 are the first sawing area, and the fourth cold saw 4 and the second fixed-length baffle 6 is the second sawing area; the first cold saw 1 and the second cold saw 2 are movable cold saws, and the third cold saw 3 is a fixed cold saw. Both the sizing baffles in the first sawing area and the second sawing area are movable sizing baffles.

[0029] The distance between the first fixed length baffle 5 and the third cold saw 3 can be adjusted by the movement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com