Automobile active air-inlet grille limiting structure

A technology of air intake grille and position-limiting structure, which is applied to the arrangement of cooling combination of power unit, power unit, vehicle components, etc., which can solve problems such as poor sealing of blades, achieve smooth switching, increase effective frontal area, and reduce wind resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

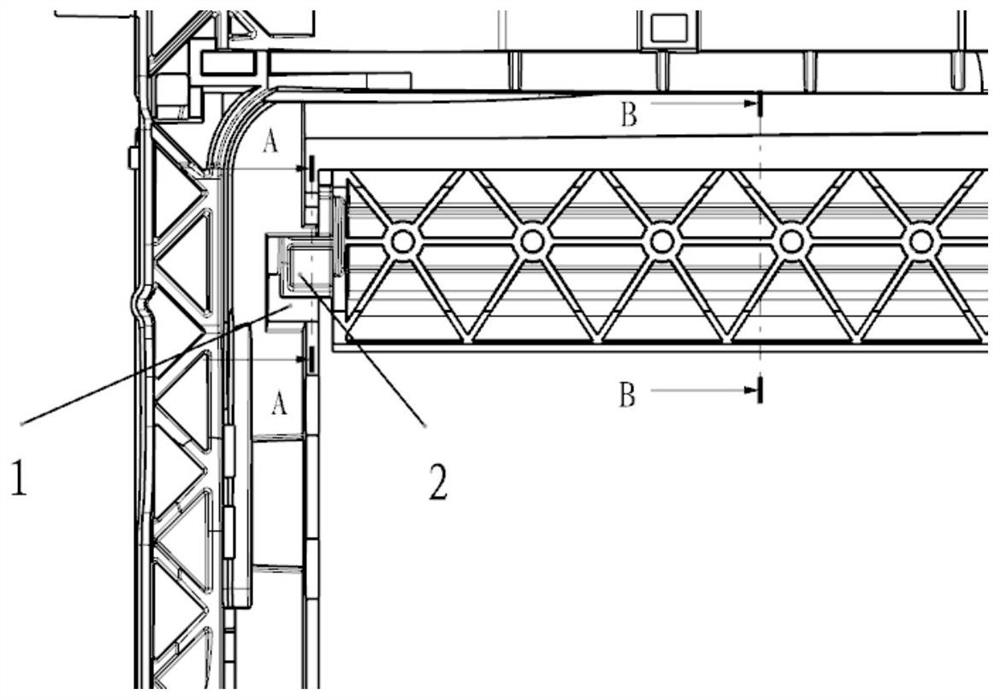

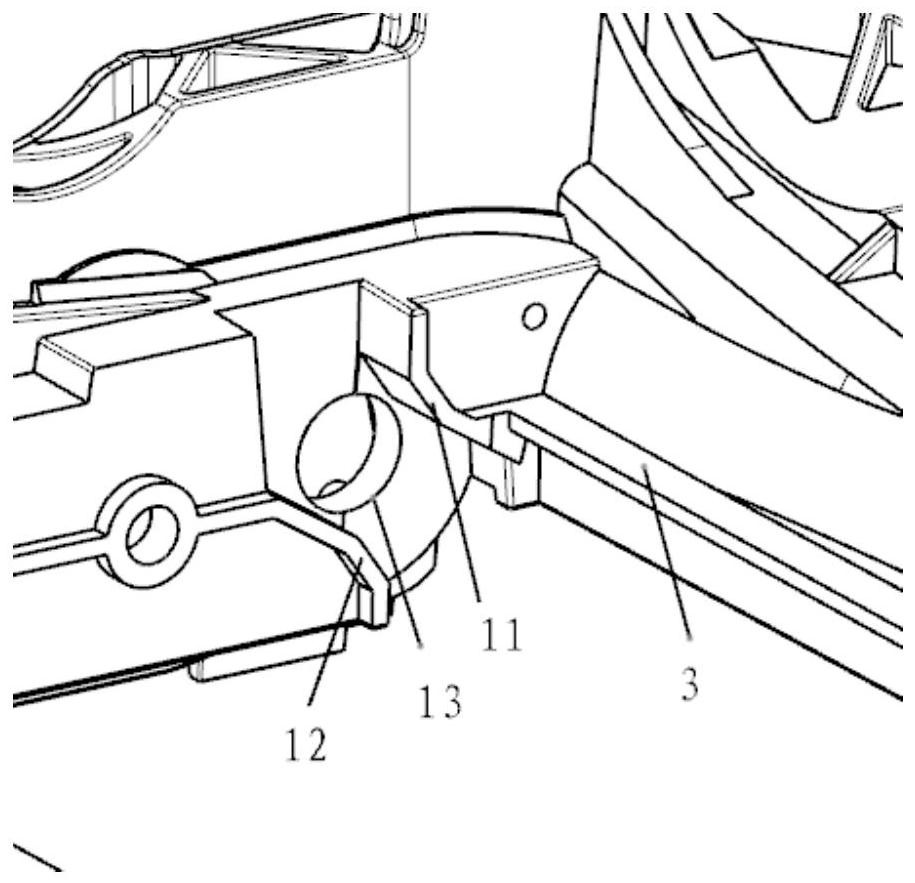

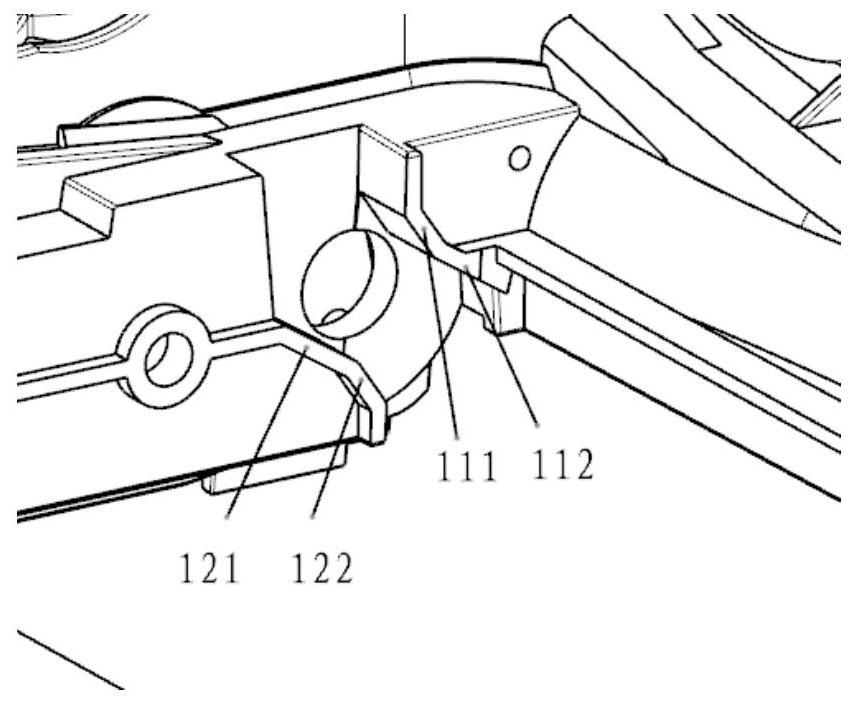

[0039] Please refer to Figure 1 to Figure 4 As shown, this embodiment provides a limiting structure for the active air intake grille of an automobile, the limiting structure includes a first limiting mechanism 1 arranged on the active air intake grille body 3 and a first limiting mechanism 1 arranged on the active blade 4 Two limit mechanisms 2, wherein the first limit mechanism 1 is installed on the active air intake grille body 3 near the installation hole of the active vane 4, and is used to limit the opening and closing limit positions of the active vane 4, and the drive shaft of the active vane passes through the active intake The air grille body 3 is installed in the installation hole and is connected with the drive mechanism (not shown) through the spline 26 on the transmission shaft. The drive mechanism can be selected from the existing drive motor. Before the drive motor is powered on, keep the active blade 4 in an unclosed state Of course, other driving mechanisms c...

Embodiment 2

[0047] Embodiment two is basically the same as embodiment one, and its difference is: combine Figure 9 and Figure 10 As shown, this embodiment provides a limiting structure for the active air intake grille of an automobile. In the illustrated embodiment, this technical solution still takes into account the deformation of the active blade 4, in order to ensure that the product lasts for a long time after assembly. For sealing performance, a layer of soft rubber layer 52 is provided for the limiting ribs that limit the active blade 4 to be in the closed state, that is to say, in this embodiment, at least a layer of soft rubber is provided on the hard rubber layer 51 of the limiting ribs A21 and C23. Adhesive layer 52, so that when the active blade 4 is in the closed state, the limiting rib A21 and the first limiting section A112 and the limiting rib C23 and the first limiting section B121 are always in contact with each other through the soft rubber layer 52, so as to ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com