Intelligent pantograph

A technology of pantograph and pantograph sliding plate, which is applied in collectors, electric vehicles, power collectors, etc., and can solve problems such as insufficient arc tolerance and frequent pantograph-catenary vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

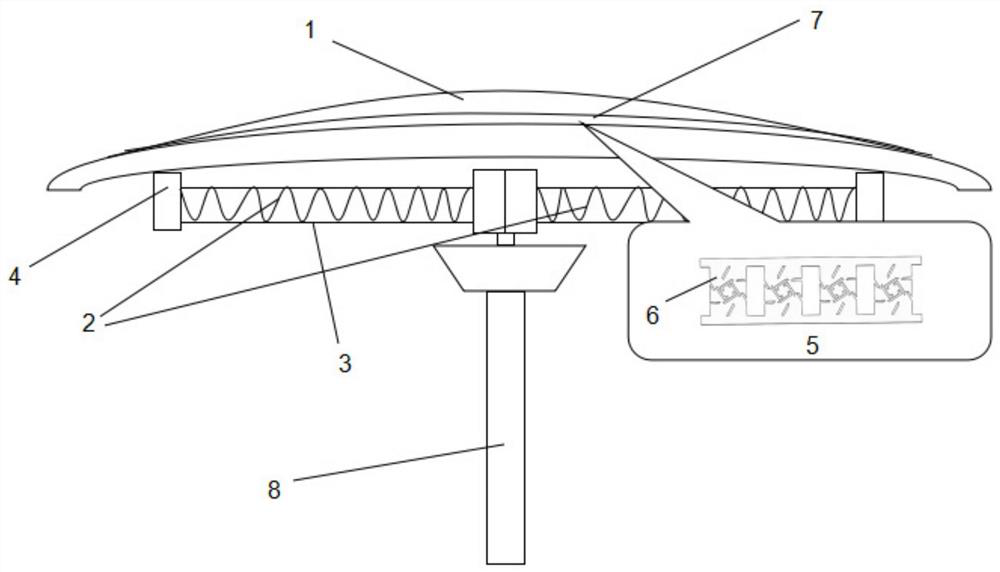

[0023] In the pantograph-catenary structure, the train obtains electric energy through the close mechanical contact between the pantograph slide and the catenary. However, when the train is running, due to various reasons, the pantograph sliding plate will inevitably vibrate, and, with the development of high-speed trains, the frequency of this vibration will become higher and higher. Therefore, it is impossible to maintain a close and good mechanical contact between the skateboard and the catenary, and there will be a short "separation" between the two due to vibration. When the two are in a non-contact state, because the pantograph-catenary current and voltage are very large, and the conditions required to generate an arc are very low, it is easy to break down the air and generate an arc between the slide plate and the catenary. In the present invention, two sets of spiral excitation coils 2 are added to the transverse support rod 3 below the pantograph to generate a transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com