A performance test system and test method for an air-cooled evaporation composite cross-flow closed cooling tower

A closed cooling tower and testing system technology, applied in the field of cooling water circulation, to achieve the effect of novel system structure, clear operating principle and diversified experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings:

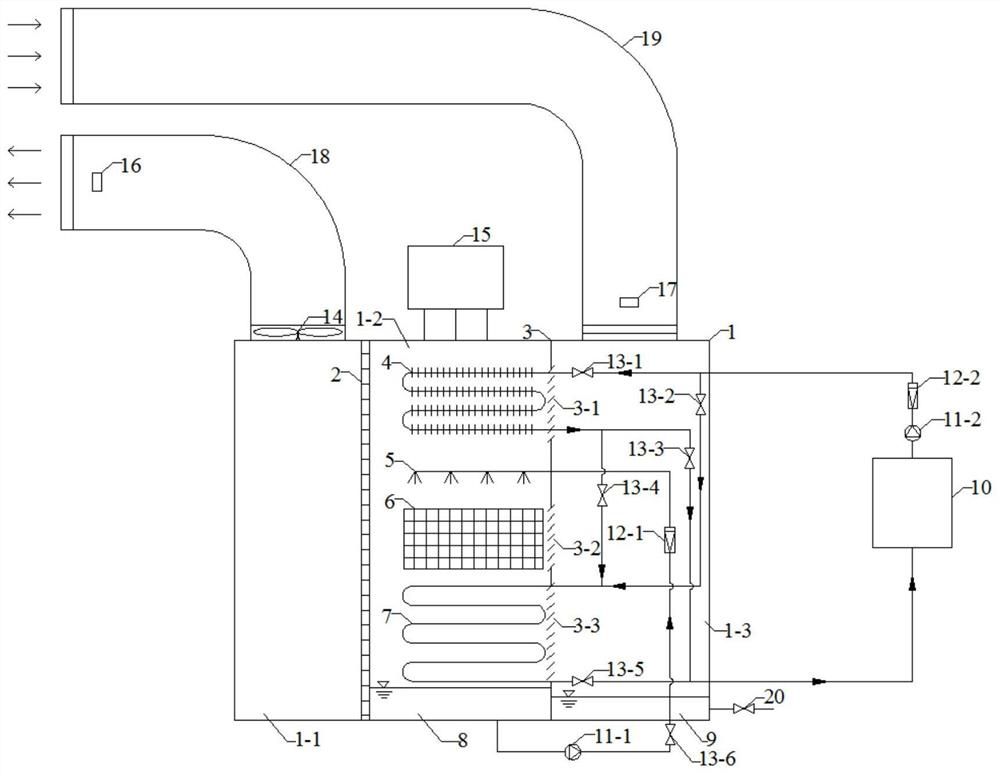

[0020] like figure 1 As shown in the figure, an air-cooled evaporation composite cross-flow closed cooling tower performance test system, the test system consists of a tower body 1, a water baffle 2, an air inlet baffle 3, a finned tube heat exchanger 4, a filler 6, a light pipe Heat exchanger 7, fan 14, data acquisition system 15, anemometer 16, temperature and humidity controller 17, air outlet duct 18, air inlet duct 19, spray water system and constant temperature inlet simulation system.

[0021] like figure 1 As shown in the figure, an air-cooled evaporation composite cross-flow closed cooling tower performance test system, the spray water system consists of a spray pipe 5, a water collection tank 8, a first circulating water pump 11-1, a first flow meter 12-1 and The sixth valve 13-6 is connected by pipes; the constant temperature inlet simulation system is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com