Cylindrical mold core wrapping force calculation method and system and server

A calculation method and technology of wrapping force, applied in calculation, computer-aided design, instrument, etc., can solve the problems of large wrapping force, deformation, inaccurate wrapping force, etc., and achieve the effect of accurate wrapping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

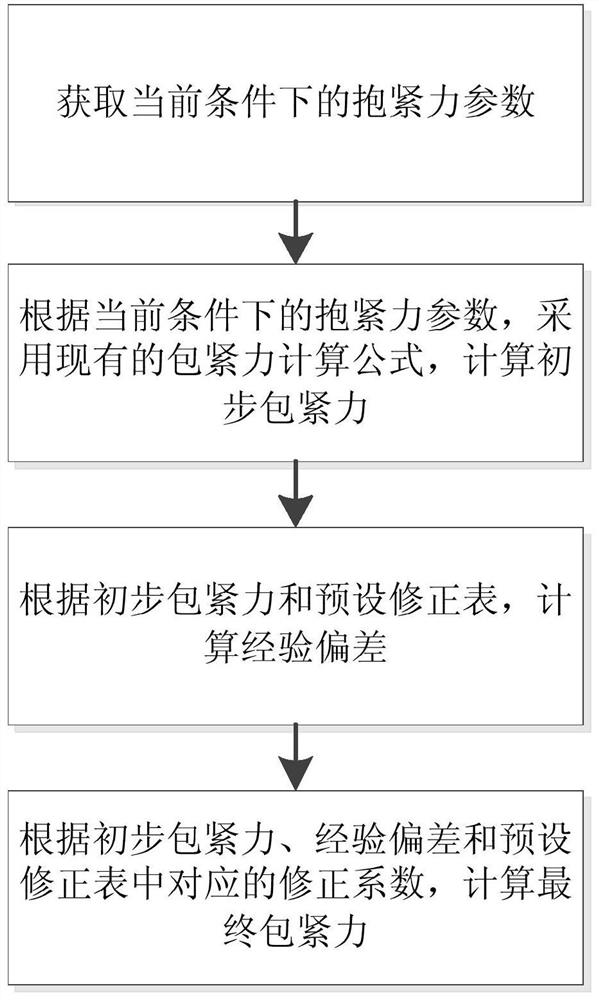

[0048] Such as figure 1 As shown, a method for calculating the clamping force of a cylindrical core includes the following steps:

[0049] Step 1, obtain the holding force parameters under the current conditions; among them, the holding force parameters include plastic elastic modulus, plastic shrinkage rate, plastic product wall thickness and plastic product inner diameter, and the information in the conditions includes plastic material information, demoulding angle information, core surface roughness information.

[0050] Step 2, according to the parameters of the clamping force under the current conditions, the preliminary clamping force is calculated by using the existing calculation formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com