Overhead transmission line stringing construction method

An overhead transmission line and construction method technology, which is applied in the field of transmission tower lines, can solve the problem of excessive deviation of line sag from a preset value, and achieve the effects of accurate tightening and harm reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

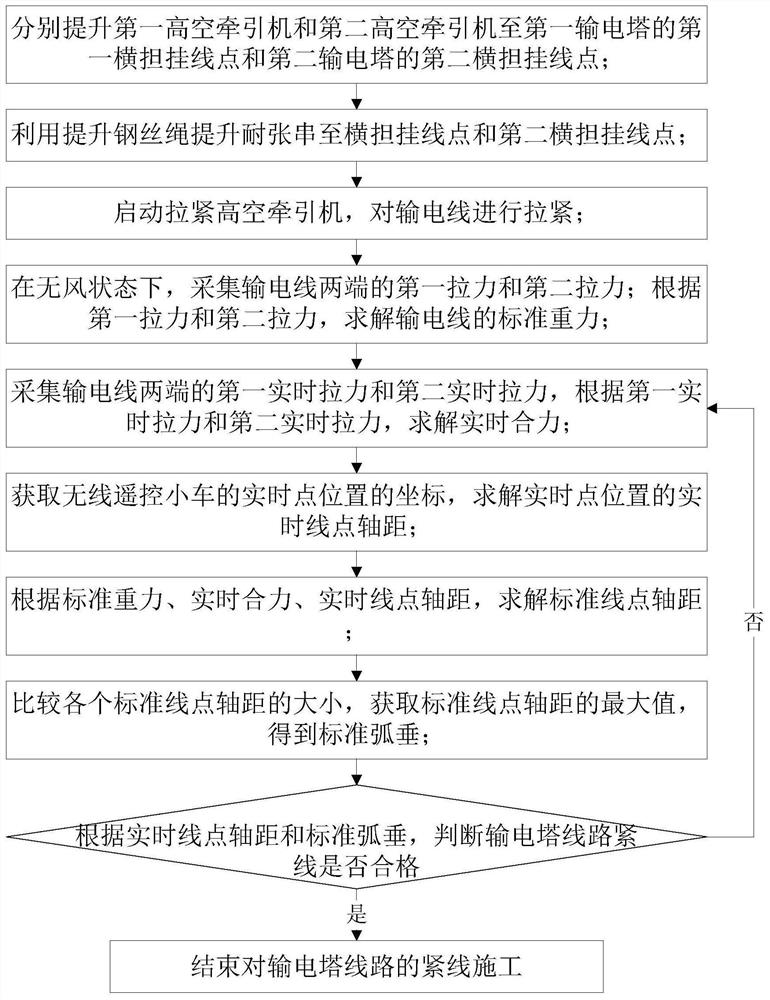

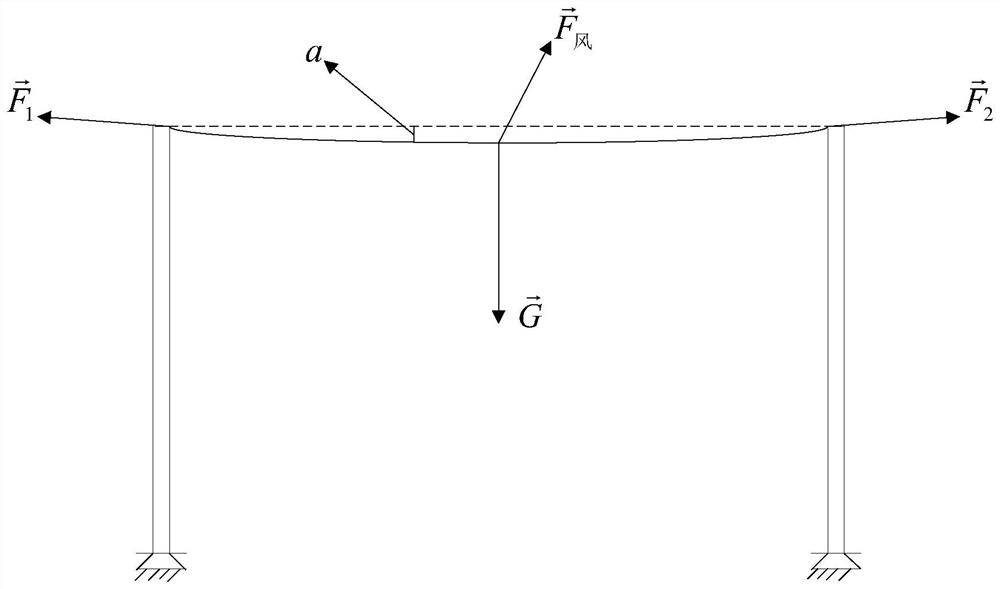

[0027] Such as Figure 1-2 As shown, in a specific embodiment of the present invention, a kind of overhead transmission line tightening construction method is provided, and the method includes the following steps:

[0028] Step S1, lifting the first high-altitude traction machine and the second high-altitude traction machine to the first cross-arm hanging point of the first power transmission tower and the second cross-arm hanging point of the second power transmission tower respectively; the first power transmission tower and The second transmission tower is two adjacent transmission towers;

[0029] Step S2, using the lifting wire rope to lift the tension string to the cross-arm hanging point and the second cross-arm hanging point; the two ends of the power line are fixed to the lifting wire rope through the power line fixing assembly;

[0030] Step S3, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com