Bubble blasting device for cooking equipment, and cooking equipment

A cooking equipment and bubble-breaking technology, which is applied in applications, cooking utensils, household appliances, etc., can solve the problems of unsatisfactory bubble-breaking effect and high energy consumption of turbo fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

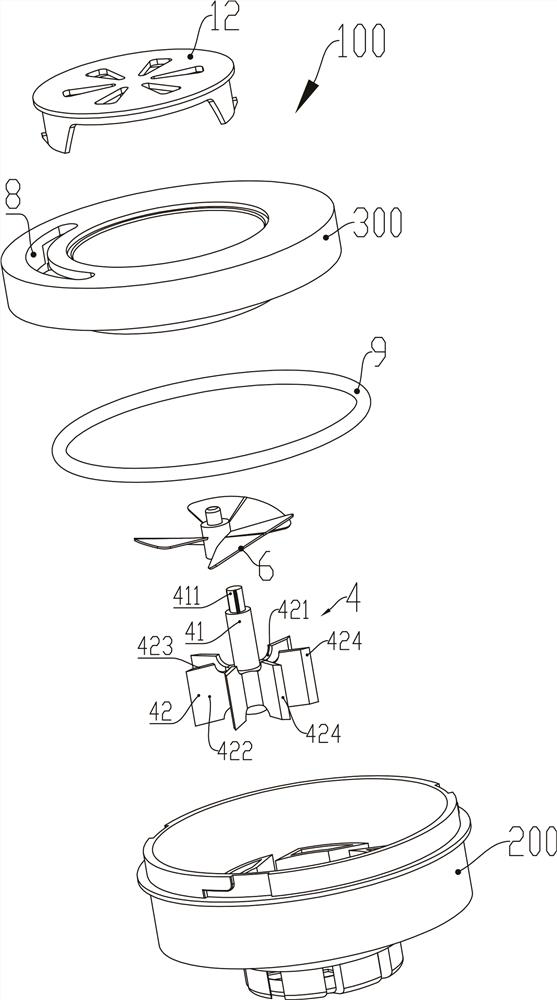

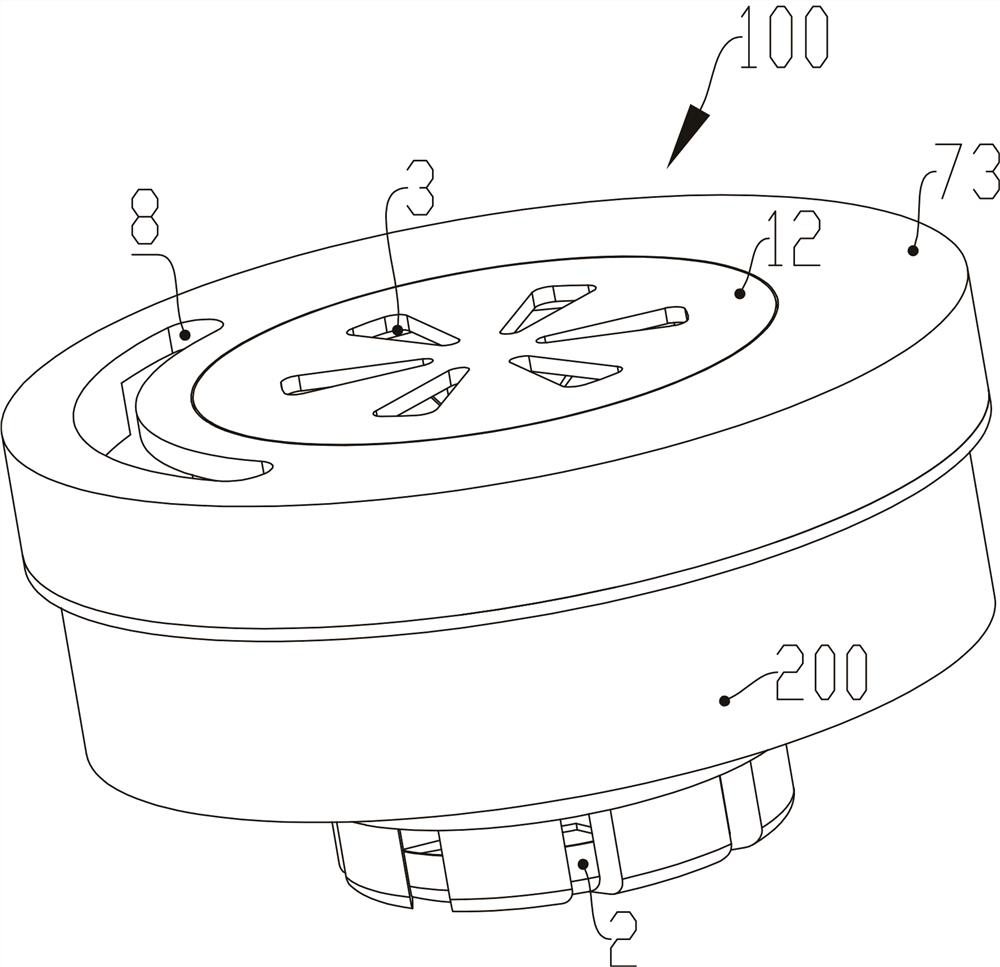

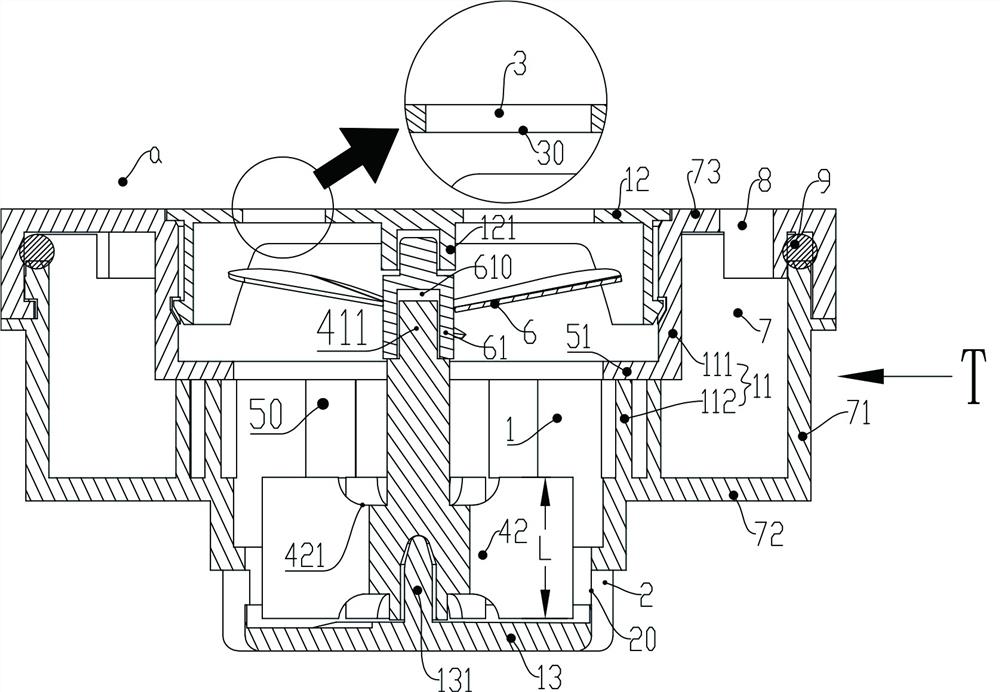

[0031] The structure of the rotary impeller 4 for the cooking equipment, the foam breaking device 100 and the cooking equipment applying the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] As shown in the figure, the bubble breaking device 100 adopts the following bubble breaking structure, including a main bubble breaking chamber 1 and a steam introduction channel 2 for cooking steam, and the steam introduction channel 2 communicates with the main bubble breaking chamber 1 for supplying The main bubble-breaking chamber 1 introduces a high-temperature bubble flow; it is characterized in that it also includes a cold air introduction channel 3, and the cold air introduction channel 3 communicates with the main bubble-breaking chamber 1 for providing an external space for the cooking equipment. The cold air of a is introduced into the main bubble-breaking chamber 1 to provide an introduction channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com