Magnetic suspension homogenizing device for nondestructive flaw detection

A non-destructive testing, magnetic suspension technology, applied in the direction of transportation and packaging, material magnetic variables, dissolution, etc., can solve problems such as uneven spraying and affecting the detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

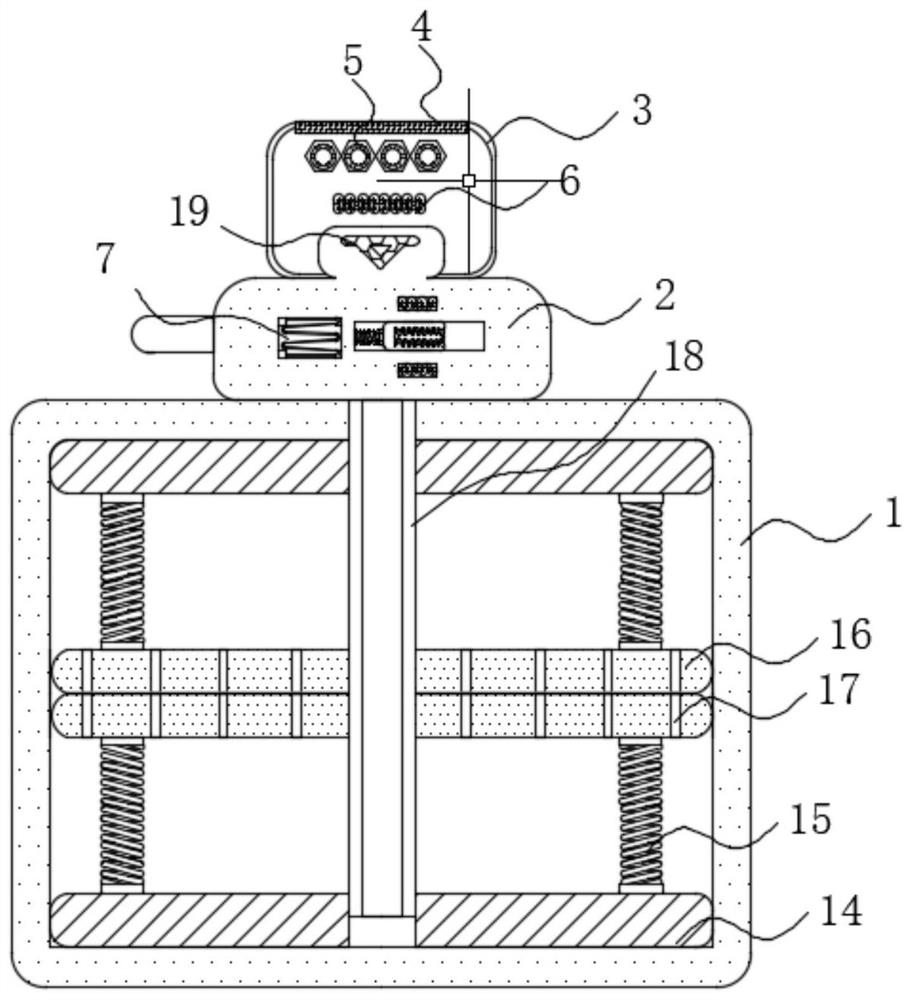

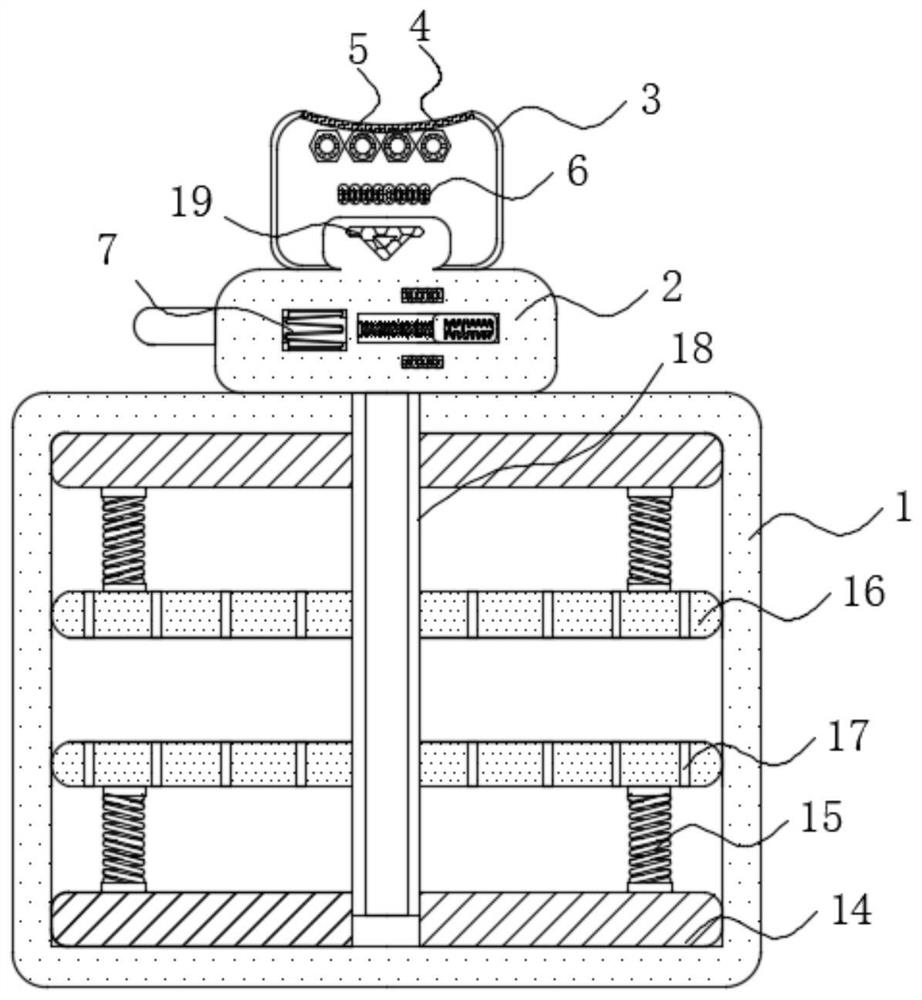

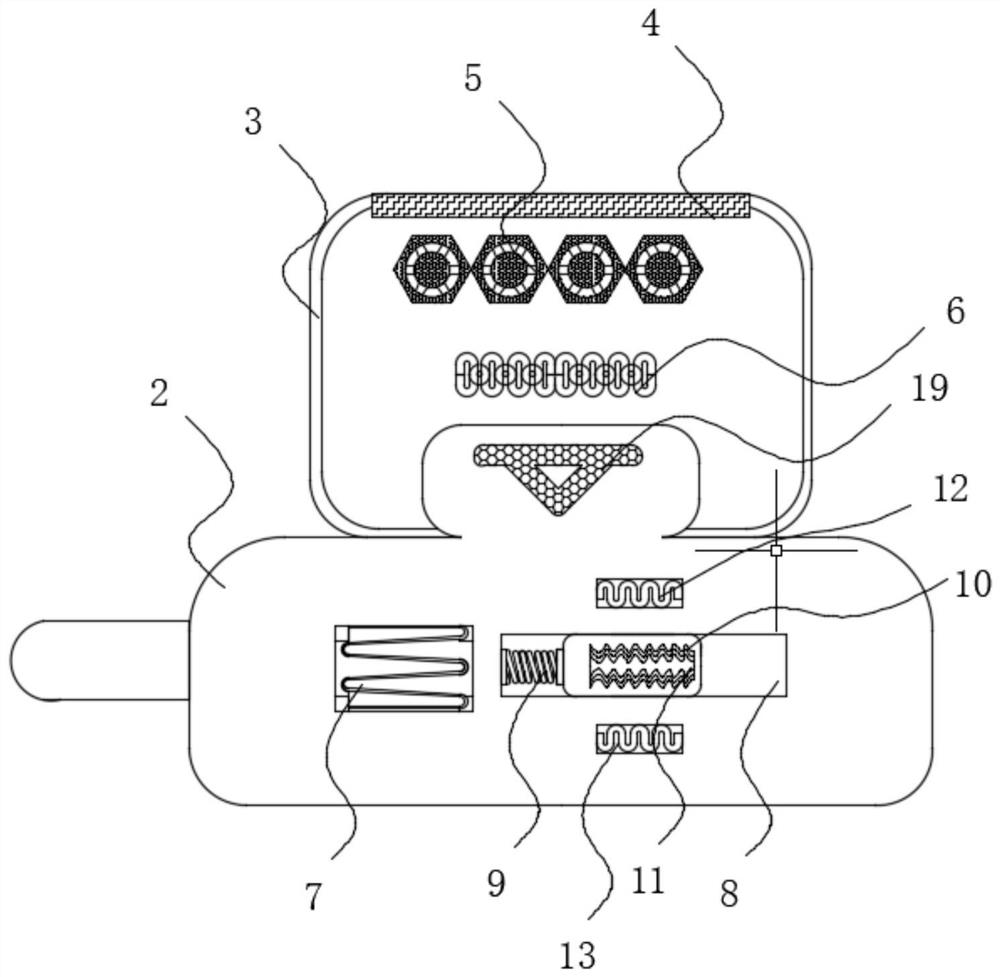

[0024]SeeFigure 1-4A homogeneous flaw detection magneto-suspension uniform apparatus, including the storage tank 1 and the spray press 2, and the top of the storage tank 1 is attached to the spray press 2, and the spray press head 2 is fixedly connected to the pressing housing 3, The top of the pressing housing 3 is fixedly connected to the elastic pressing layer 4, and the inner portion of the pressing housing 3 is fixed to the pressing case 3, the pressing housing 3 is a cylindrical structure, and the top portion of the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com