Straightness interference measuring device insensitive to incident angle

A technology of interferometric measurement and straightness, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of increased squareness measurement error, large difference in straightness slope, and reduced data reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

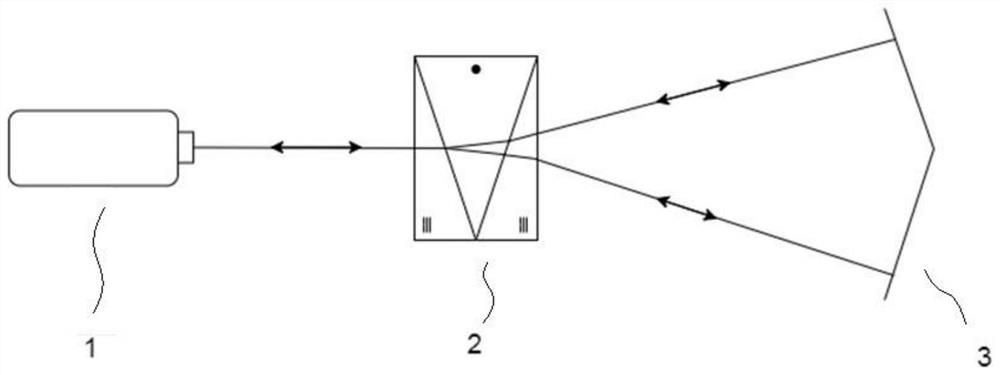

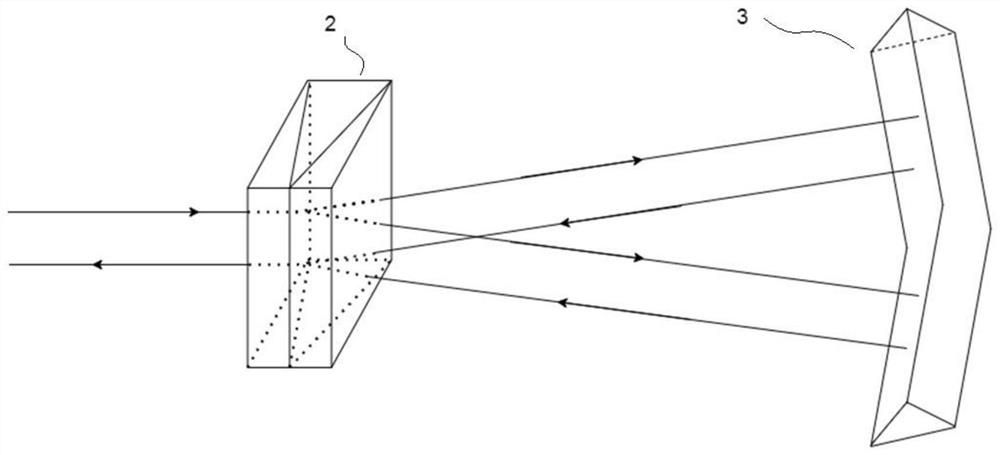

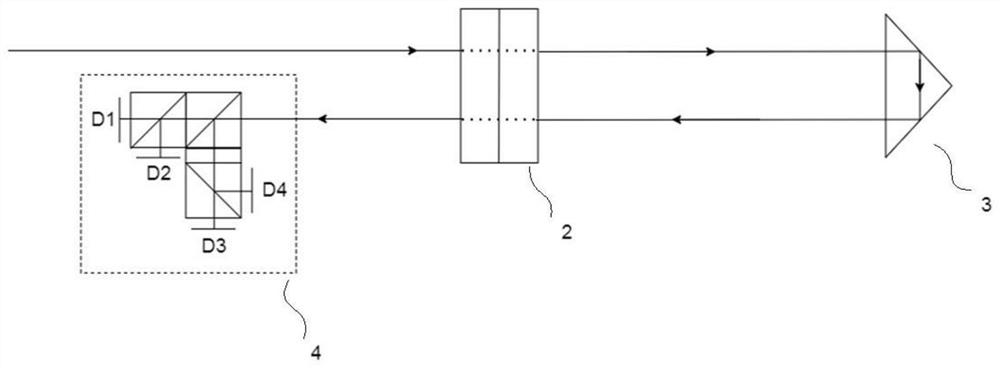

[0024] Such as Figure 1 to Figure 7 As shown, a straightness interferometric device that is insensitive to incident angle mainly includes an interferometer host system 1 , a double Wollaston prism 2 and a double-sided rectangular roof reflector 3 . The interferometer host system 1 emits a measuring beam, which is divided into two beams of orthogonally polarized light after passing through the double Wollaston prism 2, and returns to the detection and receiving unit 4 in the interferometer host system 1 after being reflected by the double-sided right-angle roof reflector 3 Analyze the interference signal and get the relative distance information. By moving the double Wollaston prism, the relative distance information of different points on the linear guide is obtained, and finally the straightness error of the linear guide is calculated....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com