Gas sensor based on photoacoustic effect

A technology of gas sensor and photoacoustic effect, which is applied in the direction of instruments, scientific instruments, and material analysis through optical means, can solve the problem of low detection sensitivity and achieve the effect of high gas concentration detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

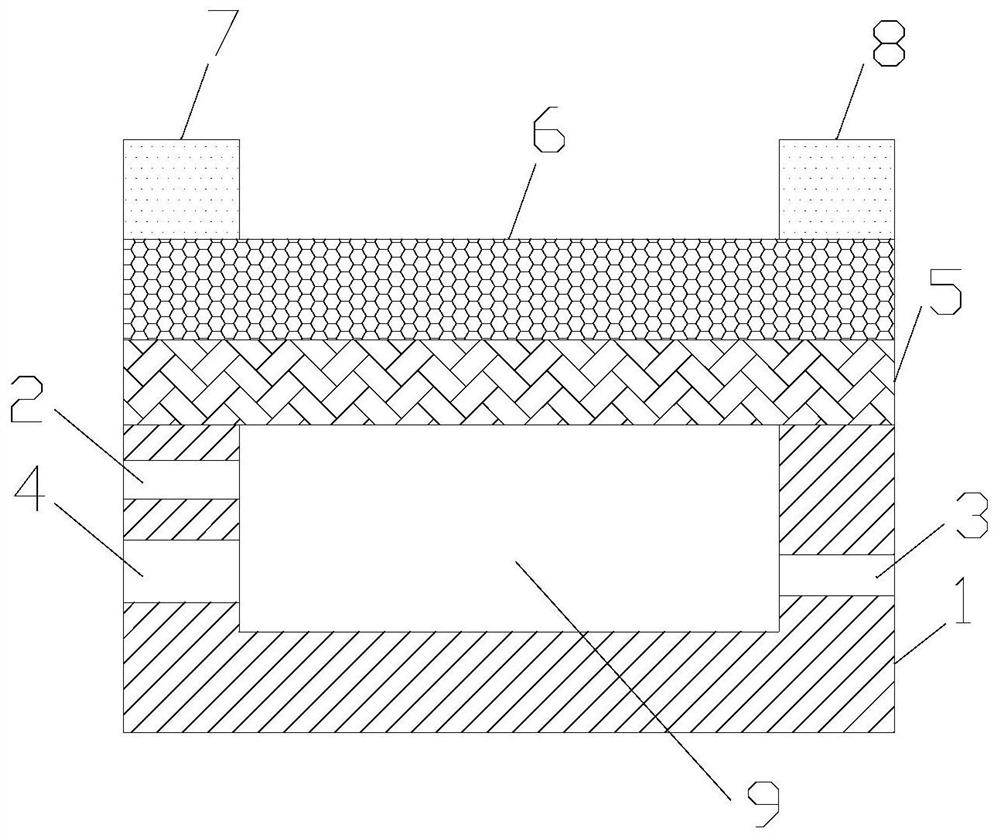

[0020] The invention provides a gas sensor based on the photoacoustic effect, such as figure 1 As shown, it includes a cavity wall 1 , an air inlet 2 , an air outlet 3 , a light-transmitting hole 4 , an elastic layer 5 , an electric sensitive layer 6 , a source 7 , and a drain 8 . The chamber wall 1 includes side surfaces and a bottom surface. The air inlet 2 and the air outlet 3 are arranged on opposite sides of the chamber wall 1 . exist figure 1 Among them, the air inlet 2 is set on the left side of the cavity wall 1, and the gas outlet 3 is set on the right side of the cavity wall 1. The light-transmitting hole 4 is arranged on the side of the chamber wall 1 , and the light-transmitting hole 4 is on the same side as the air inlet 2 . The light-transmitting hole 4 is used to introduce an external laser into the cavity wall 1 . The light hole 4 is a transparent material. The elastic layer 5 covers the chamber wall 1 , and the elastic layer 5 and the chamber wall 1 enclo...

Embodiment 2

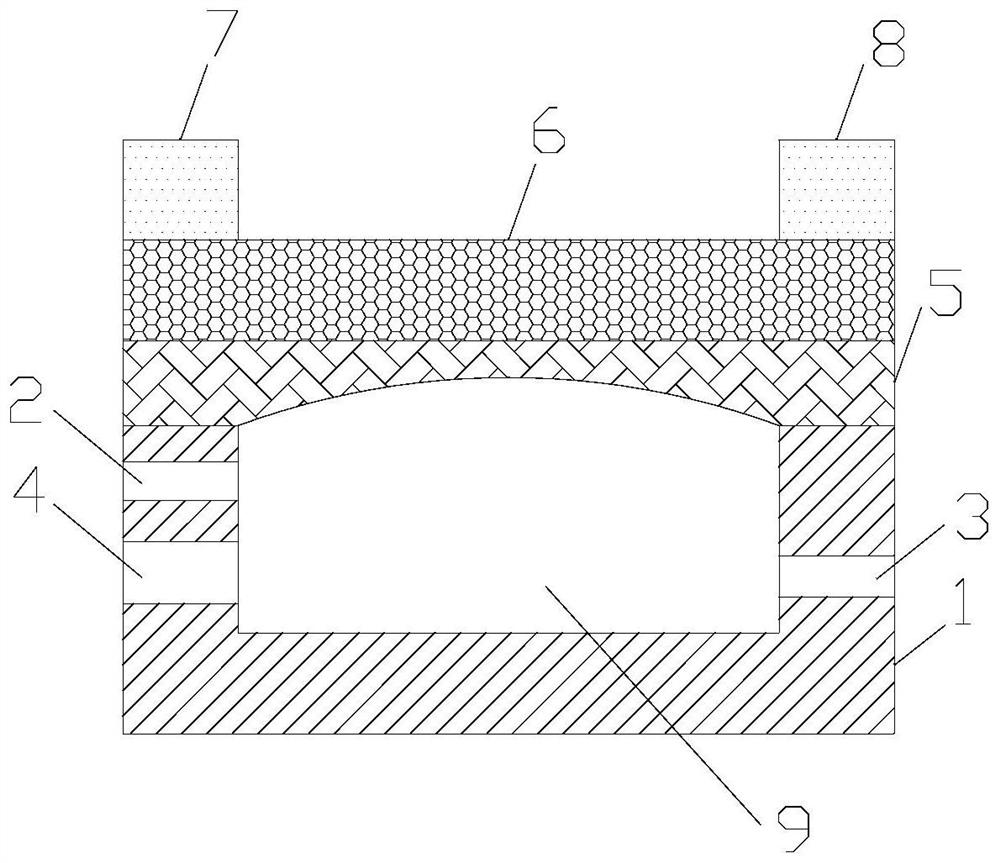

[0024] On the basis of Example 1, such as figure 2 As shown, the elastic layer 5 is thin in the middle and thick in the edges. In this way, when the gas to be measured absorbs the laser light and expands, the elastic layer 5 deforms to a greater extent, thereby changing the electrical conductivity of the electrosensitive layer 6 more, thereby realizing gas detection with higher sensitivity.

Embodiment 3

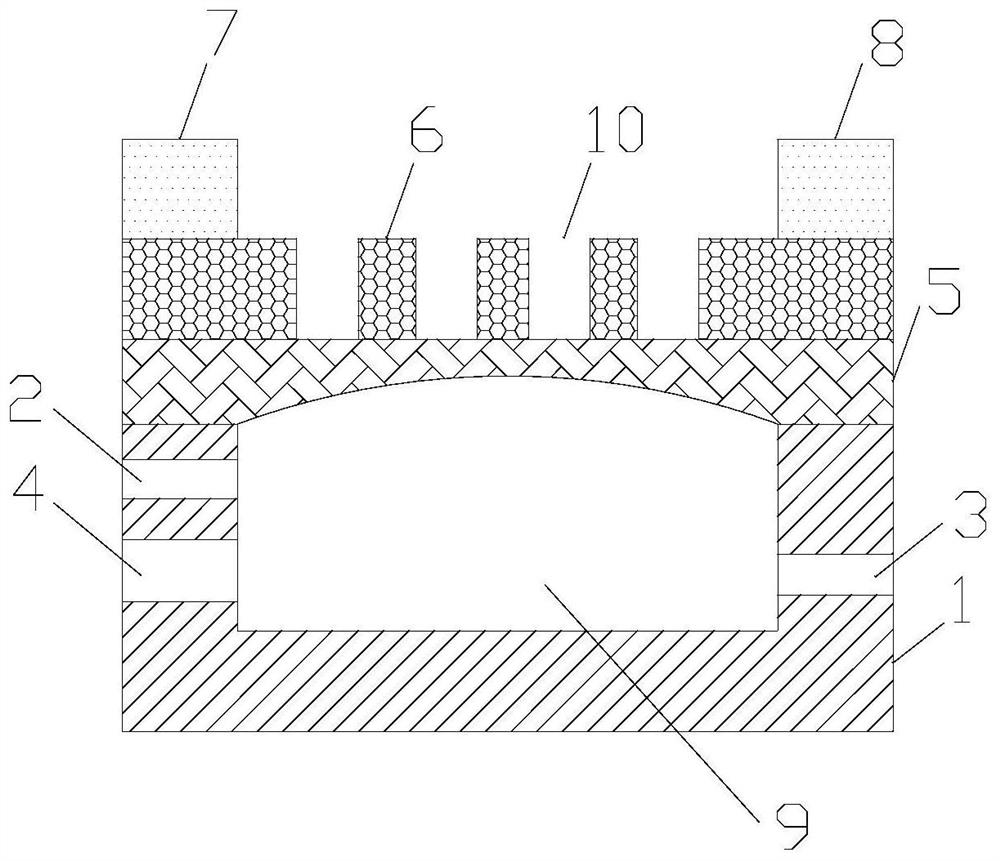

[0026] On the basis of Example 2, such as image 3 As shown, there are holes 10 in the graphene layer. In this way, the current in the graphene layer is confined to a narrower path. When the graphene layer is deformed, the current distribution in the graphene layer changes more significantly, which leads to a greater change in the conductive properties of the graphene layer, thereby achieving higher sensitivity gas detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com