High-power-density outer rotor permanent magnet motor heat dissipation device based on heat dissipation copper pipe technology

A high-power-density, heat-dissipating copper pipe technology, applied in electromechanical devices, cooling/ventilation devices, electrical components, etc., can solve problems such as high local temperature and large winding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

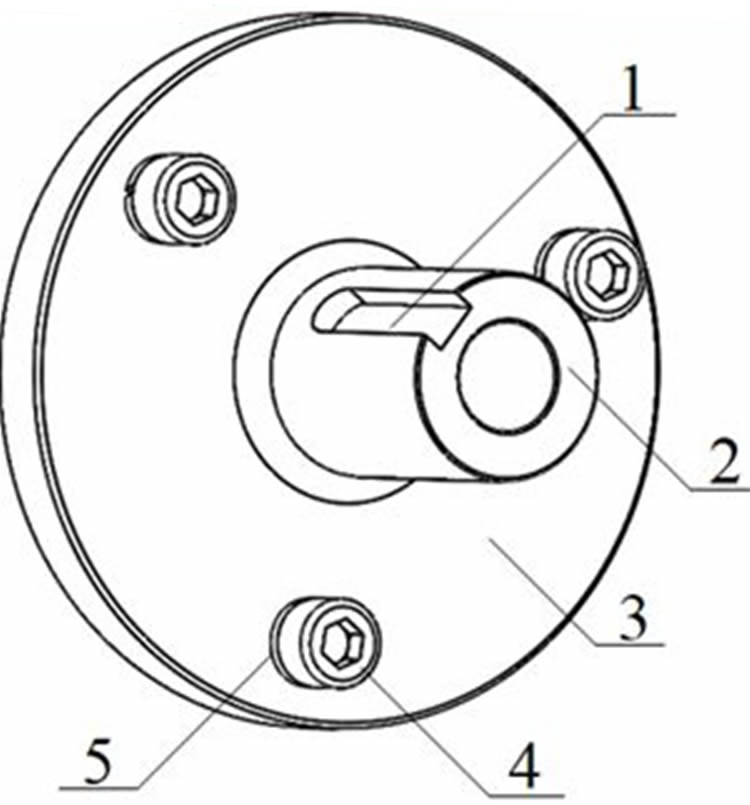

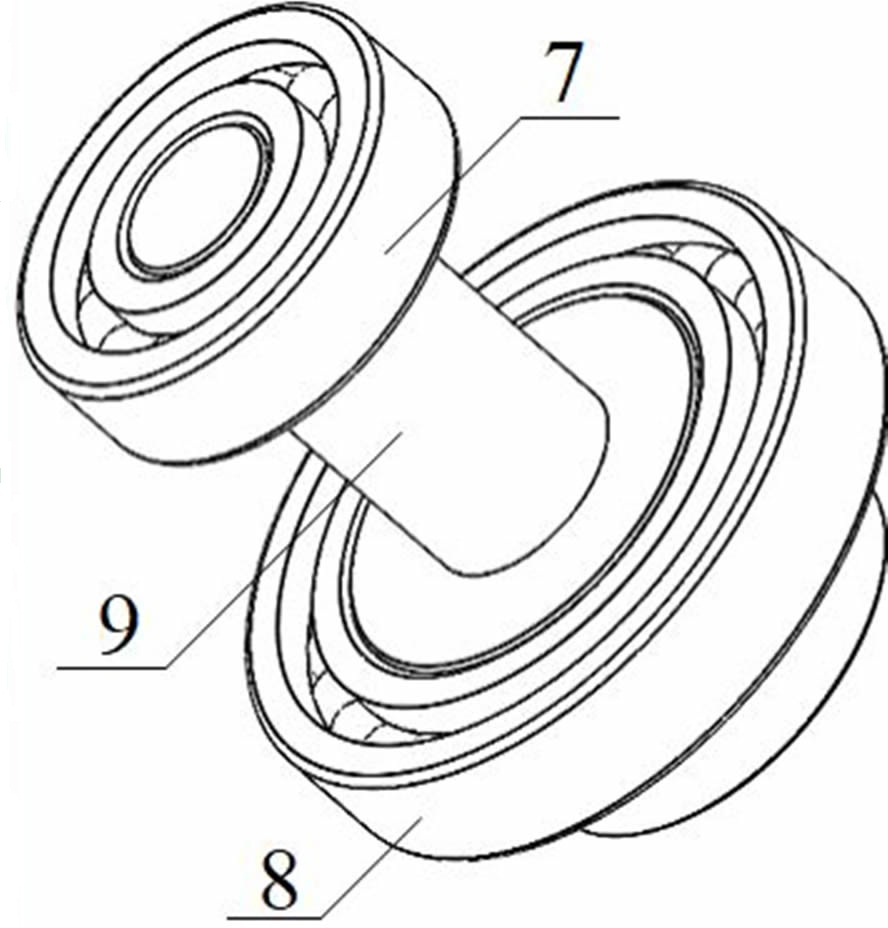

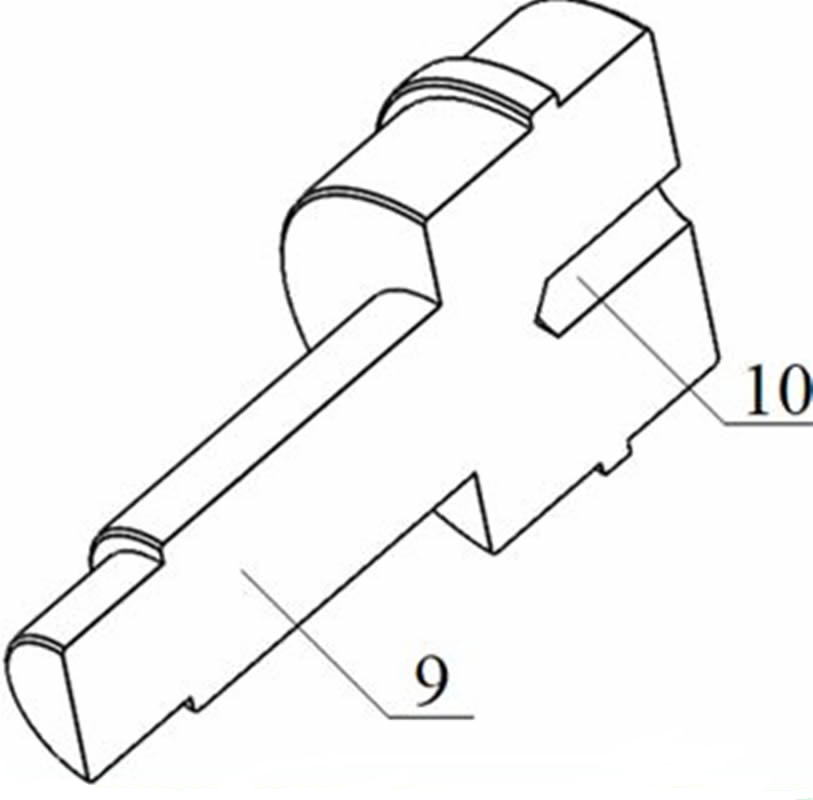

[0049] Specific embodiment 1: The method for fixing both ends of the heat dissipation copper pipe. The heat-absorbing end of the heat dissipation copper pipe is inserted into the round hole of the yoke of the stator core. The outer diameter of the stator core can be 10.0mm, so that the round hole of the stator core yoke and the copper tube can fully contact and transfer heat better. Considering the influence of the processing technology, there is no guarantee that there is an air gap between the two, and it is necessary to inject a thermally conductive adhesive with a high thermal conductivity inside to transfer heat better. The heat release end of the heat dissipation copper tube and the sun flower radiator adopt the same installation process as the round hole of the yoke of the stator core.

specific Embodiment 2

[0050]Specific embodiment 2: winding end potting technology, the temperature rise of the winding end of high power density permanent magnet motor is relatively high, in order to reduce the winding temperature rise, the process of winding end potting is usually adopted, but the existing winding end potting The heat dissipation of the winding end is limited; therefore, in the patent of the present invention, the heat dissipation copper pipe and the winding end are potted together, and the heat at the winding end is transferred to the outside through the heat dissipation copper pipe, which improves the heat dissipation efficiency; at the same time, the potting The glue plays a role in fixing the copper pipe, preventing the heat dissipation copper pipe from vibrating when the motor is running, resulting in a reduction in the heat dissipation efficiency of the heat dissipation copper pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com