Pull riveting type tire repairing nail

A riveting and tire nail technology, which is applied in the field of riveting tire repair nails, can solve problems such as tire bulging, increased use cost, and tire blowout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

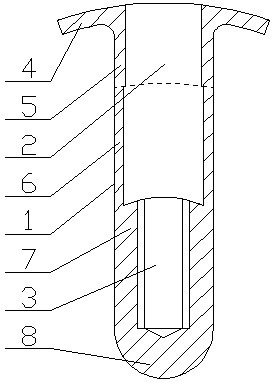

Embodiment 1

[0050] Such as figure 1 , Figure 4 , Figure 5 , Figure 7 with Figure 10 It can be seen that the riveting type tire repair nail includes a nail body 1, one end of the nail body 1 is provided with a slot A2 along the axial direction of the nail body 1, and the bottom of the slot A2 is connected with a slot B3 , the inner wall of the slot B3 is provided with an internal thread, the inner diameter of the slot A2 is greater than or equal to the major diameter of the internal thread of the slot B3, and one end of the nail body 1 provided with the slot A2 is provided with a flanging outward A4, the part of the nail body 1 corresponding to the slot hole A2, along the direction from the flanging A4 to the slot hole B3, is a reinforcement part 5 and a deformation part 6 in sequence, and the strength of the reinforcement part 5 is greater than that of the deformation part 6 , the part of the nail body 1 corresponding to the slot B3 is the tension part 7, and the flange A4 is an a...

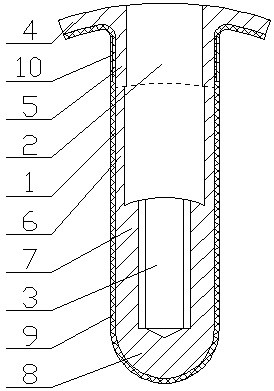

Embodiment 2

[0054] Such as figure 2 , Figure 4 , Image 6 , Figure 8 with Figure 11 It can be seen that the riveting type tire repair nail includes a nail body 1, one end of the nail body 1 is provided with a slot A2 along the axial direction of the nail body 1, and the bottom of the slot A2 is connected with a slot B3 , the inner wall of the slot B3 is provided with an internal thread, the inner diameter of the slot A2 is greater than or equal to the major diameter of the internal thread of the slot B3, and one end of the nail body 1 provided with the slot A2 is provided with a flanging outward A4, the part of the nail body 1 corresponding to the slot hole A2, along the direction from the flanging A4 to the slot hole B3, is a reinforcement part 5 and a deformation part 6 in sequence, and the strength of the reinforcement part 5 is greater than that of the deformation part 6 , the part of the nail body 1 corresponding to the slot B3 is the tension part 7, and the flange A4 is an a...

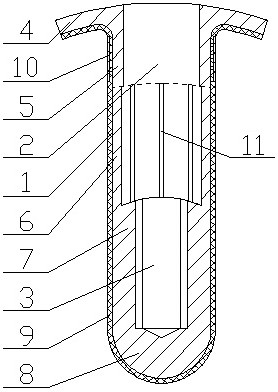

Embodiment 3

[0057] Such as image 3 , Figure 4 , Image 6 , Figure 9 with Figure 12 It can be seen that the riveting type tire repair nail includes a nail body 1, one end of the nail body 1 is provided with a slot A2 along the axial direction of the nail body 1, and the bottom of the slot A2 is connected with a slot B3 , the inner wall of the slot B3 is provided with an internal thread, the inner diameter of the slot A2 is greater than or equal to the major diameter of the internal thread of the slot B3, and one end of the nail body 1 provided with the slot A2 is provided with a flanging outward A4, the part of the nail body 1 corresponding to the slot hole A2, along the direction from the flanging A4 to the slot hole B3, is a reinforcement part 5 and a deformation part 6 in sequence, and the strength of the reinforcement part 5 is greater than that of the deformation part 6 , the part of the nail body 1 corresponding to the slot B3 is the tension part 7, and the flange A4 is an ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com